PACC Anlage zur kontinuierlichen Herstellung von Öl, computergesteuert (PC)

INNOVATIVE SYSTEME

Computer Controlled Continuous Cycle Oil Production Plant, "PACC", designed by EDIBON, allows the teaching and research of the process of obtaining olive oil, measuring the acidity of the oil, as well as the study of the yield of the process.

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

Computer Controlled Continuous Cycle Oil Production Plant, "PACC", designed by EDIBON, allows the teaching and research of the process of obtaining olive oil, measuring the acidity of the oil, as well as the study of the yield of the process.

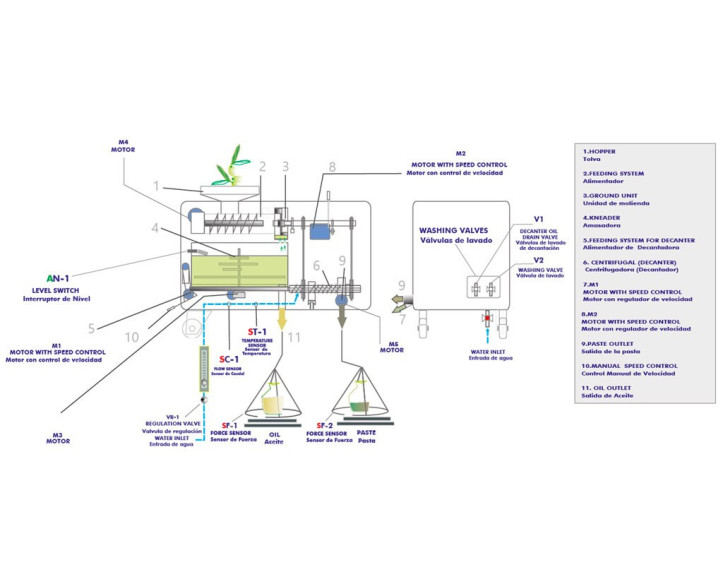

Computer Controlled Continuous Cycle Oil Production Plant, "PACC", is integrated by the following elements:

- Hopper. At this point the previously cleaned and selected olives are introduced and from here the olives are conveyed to a mill by means of a screw conveyor.

- Mill. Here the olives are milled to produce a heterogeneous paste that will be treated in the mixer.

- Mixer. The mixing of the paste takes place during a time never less than 45 minutes, obtaining a homogeneous mixture that will reach the decanter through an endless screw.

- Decanter. Here the oil extraction takes place. The quality and quantity is determined by the type of olive. The extraction is carried out by a two-stage horizontal centrifugation. The decanter has six pairs of screws that control the amount of oil extracted. Depending on the yield of the olive introduced in the process, the interface, oil, alpechín and paste will occur in the vicinity of one of these circles.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Obtaining of Extra Virgin Oil.

- Measurement of the acidity of the obtained oil.

- Determination of the performance depending on the decanter centrifugation speed.

- Determination of the performance depending on the type of used olive.

- Study of the influence of the collection time in the performance.

- Comparative study of the oil performance depending if the olive has been just recollected or if previously it has been put out in the sun to dry.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Study of the Hysteresis of the flow sensor.

- Decanter supply system calibration.

- Study of the obtaining of oil from different food products.

- Determination of the performance depending on the type of food product used for oil production.

- Comparative study of the oil performance depending if the food product for its production has been just recollected or if previously it has been put out in the sun to dry.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PACC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PACC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Sprühtrockner, computergesteuert (PC)

Sprühtrockner

Gerät für Sprühtrocknung und -kühlung, computergesteuert (PC)

Mehrzweckverarbeitungsbehälter, computergesteuert (PC)

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät zur Hydrierung, computergesteuert (PC)

Gerät zur Desodorierung, Computergesteuert (PC)

Fortschrittliches Gerät zur Desodorierung, Computergesteuert (PC)

Didaktisches Gerät für die Abfüllung von Flüssigkeiten, computergesteuert (PC)

Didaktisches Gerät für die Verpackung von Feststoffen, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen