At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-SLB Ball Selection Workstation

INNOVATIVE SYSTEME

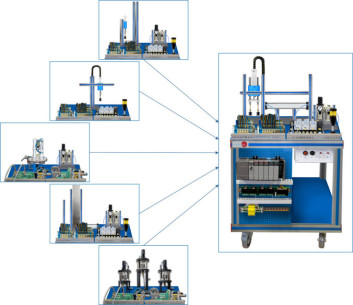

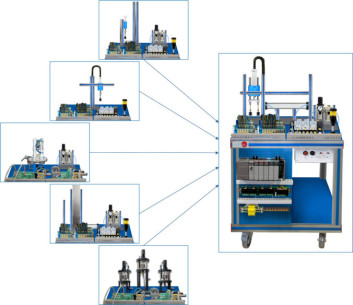

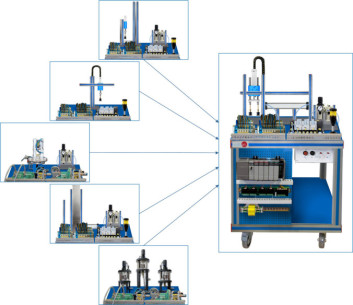

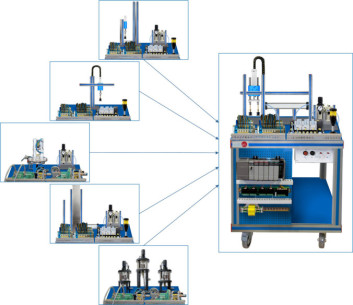

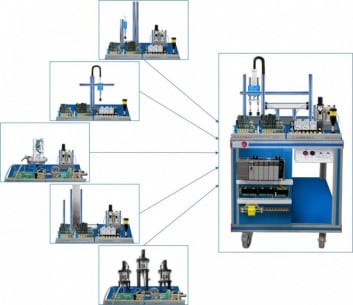

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes.

Erweiterungen

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes.

The "AE-PLC-SLB" is a ball selection system commanded by a PLC. The workstation detects balls that arrive to the collect position and, according to the color and material, a cylinder guides the balls to the correct container. The system is equipped with different sensors in order to identify the balls.

The "AE-PLC-SLB" workstation is designed as a modular system to facilitate the understanding.

The main components are:

- The PLC: is composed of the CPU unit and all additional modules needed to ensure the correct operation of the workstation.

- The Control Panel: with start/stop button, emergency pushbutton, reset button, light indicators to show the current state of the process, etc.

- The Pneumatic Circuit: contains the required solenoid valves, pressure components, filters, and regulators to ensure the proper functioning of the unit.

- The Workstation: is composed of real industrial components used by rotary table systems such as reed sensors, presence sensors, DC motor, inductive sensors, rotary table with 8 positions, etc.

- The "AE-PLC-MR1" is an independent workstation that can work alone and/or in conjunction with other workstations to form a complete Flexible Manufacturing System*.

The list of products of flexible manufacturing systems is available in the "6.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS" area.*

The pneumatic circuit and the workstation are distributed in the following sections:

- Air Treatment System: contains a filter-regulator block with a water trap and shut-off valve to control the air pressure input to the unit. Includes a dual-scale pressure gauge to visualize the pressure level supplied to the unit.

- Parts Feeding Section: contains a sloped ramp for storing the parts. The parts are supplied to the unit one by one through a double-acting cylinder. Each of the two inputs of the double-acting cylinder has an adjustable airflow valve with a bypass to regulate the cylinder speed.

- Parts Verification Section: designed to classify the parts, the four parts with different characteristics will be classified into four storage areas by activating three actuators. The three sorting actuators are double-acting and each has an adjustable airflow valve with a bypass and a pilot-operated check valve to regulate the cylinder speed and block its position in case there is no air input in the double-acting cylinder.

- Parts Sorting Section: designed to classify the parts, the four parts with different characteristics will be classified into four storage areas by activating three actuators. The three sorting actuators are double-acting and each has an adjustable airflow valve with a bypass and a pilot-operated check valve to regulate the cylinder speed and block its position in case there is no air input in the double-acting cylinder.

- Signaling Tower: contains green, yellow, and red LED lights to indicate the system’s status.

- Solenoid Valve Block: it is a distributor block of pneumatic valves with twelve solenoid valves, two of which function as 3/2 monostable solenoid valves, six as 5/2 monostable solenoid valves, and four as 5/2 bistable solenoid valves.

- Electrical Terminal Block: contains all accessible and identified unit signals for manual unit checking. The electrical terminal block has color-coded terminals to help the user identify the type of each signal, and it also contains the name of each signal.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Introduction to the flexible manufacturing system: Identification of unit components.

- Introduction to pneumatics and electro-pneumatics: Identification of components.

- Configuration of a pneumatic application.

- Operation of pneumatic system: Introduction to pneumatic actuators.

- Study of sensor detection.

- Manual control and study of inductive and color sensors.

- Industrial application of a ball sorting system.

- Modification of elevator process parameters and process time optimization.

- Fault inserted analysis and diagnosis.

ÄHNLICHE VERFÜGBARE GERÄTE

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-VS

The "AE-PLC-VS" is a quality control system commanded by a PLC. The "AE-PLC-VS" is equipped with a color camera that identifies the pieces on a conveyor belt. Depending on different specification, the system separates the corresponding pieces...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CF

Sorting Workstation

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places. The "AE-PLC-CF" workstation is designed as a modular system...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-RFID

RFID identification Workstation

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SIP

Pieces Identification Workstation

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CPD

Defective Pieces Sorter Workstation Application

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

ERGÄNZENDE AUSRÜSTUNG

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SIP

Pieces Identification Workstation

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-VS

Quality Control Workstation

The "AE-PLC-VS" is a quality control system commanded by a PLC. The "AE-PLC-VS" is equipped with a color camera that identifies the pieces on a conveyor belt. Depending on different specification, the system separates the corresponding pieces...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CF

Sorting Workstation

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places. The "AE-PLC-CF" workstation is designed as a modular system...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-RFID

RFID identification Workstation

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CPD

Defective Pieces Sorter Workstation Application

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen