At EDIBON, we reaffirm our commitment to the advancement of clean and renewable energy, with a special focus on green hydrogen as a key driver for a more sustainable future. We are proud to have been selected to equip the first Green Hydrogen Laboratory in the Region of Murcia, a pioneering space...

The shift towards electric vehicles (EVs) has gained considerable momentum worldwide, promising a reduction in greenhouse gas emissions and a path to a more sustainable future. However, as the demand for EVs accelerates, so too does the need for large quantities of essential minerals, such as...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

With the new smart bidirectional meters, all protection and control devices and the wide use of Internet, the grid has become an intelligent (smart) grid.

The growing concern over pollution and climate change has exponentially increased the interest about clean energies. Computer Controlled Renewable Energies units (with SCADA), designed by EDIBON, are not only an effective learning tool to understand all energy related processes, but also a...

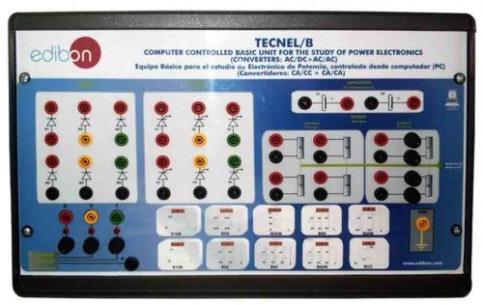

On December 1st, the Repair Course for Small Laboratory Equipment, taught by our engineers at the EDIBON facilities, was completed, lasting 4 days.

The attendees, (Laboratory technicians and maintenance of the Rey Juan Carlos University of Madrid) had the opportunity to perform multiple...

Cookie-Präferenzen

Cookie-Präferenzen