At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

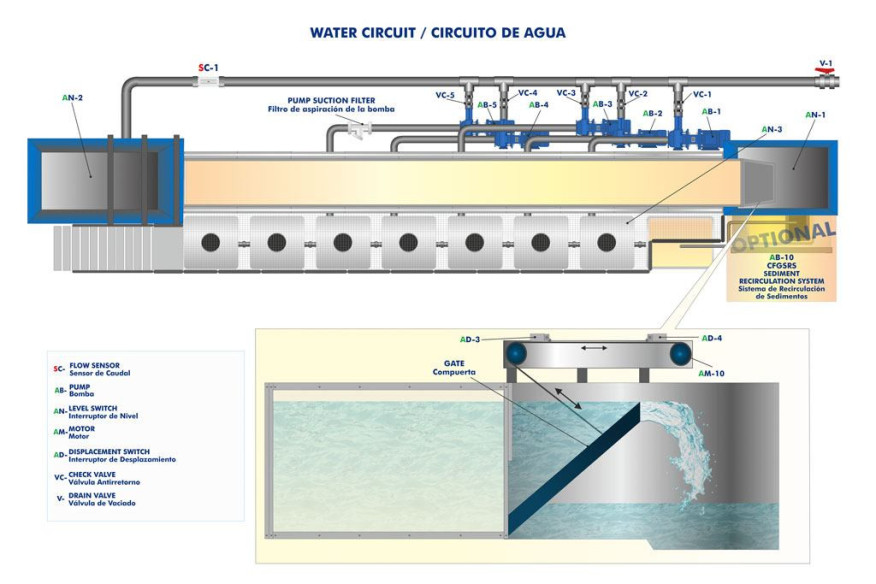

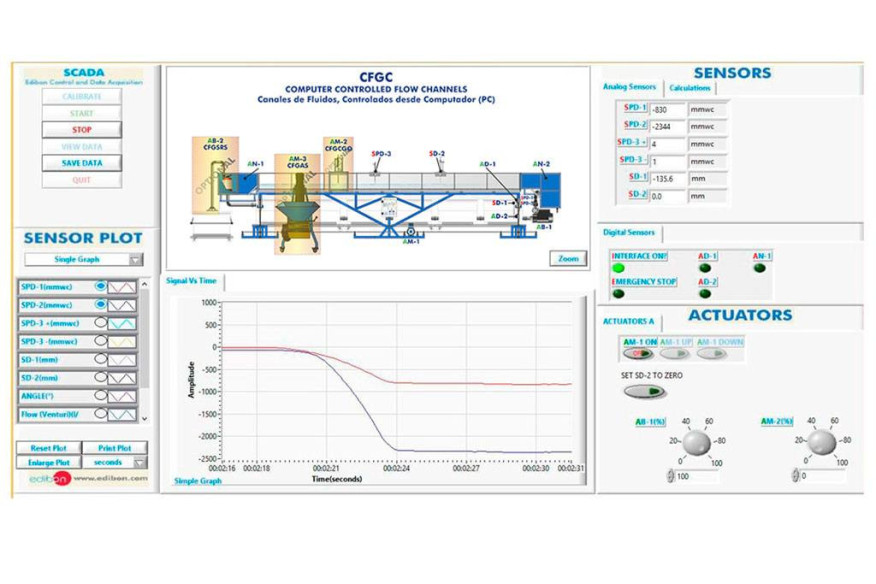

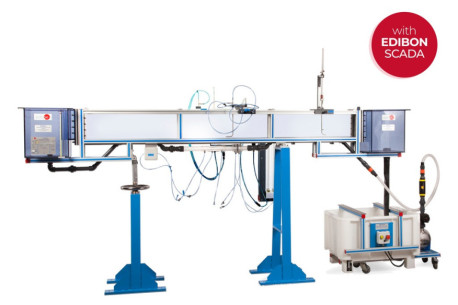

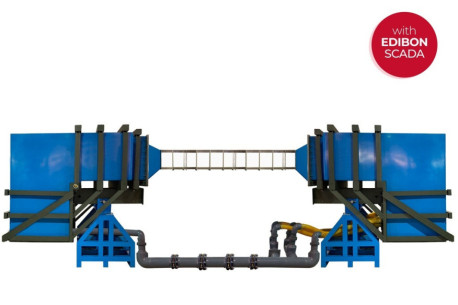

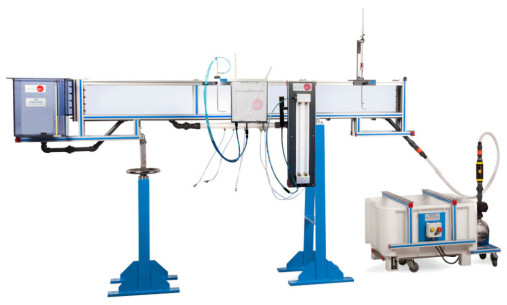

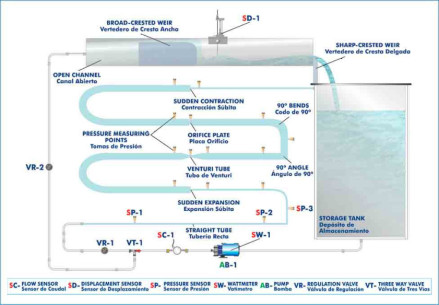

We are pleased to announce our latest installation at , Giurisprudenza - Università degli studi di Napoli Federico II, specifically for the department of Civil, Building and Environmental Engineering. There we install our CFGSMI/300, CFGPRE, CFGC10SP/300, CFGBAE/300 and CFG10SP-KIT/300...

We would like to thank everyone at the Università degli Studi di Napoli Federico II (Italy) Unina News for their hospitality, where we carried out the installation of the Computer Controlled Flow Channels, with SCADA CFGC for the Civil Construction and Environmental Engineering department. This...

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Fluid Mechanics and learn about #fluids properties. #DiscoverEdibon #Engineering.

Cookie-Präferenzen

Cookie-Präferenzen