CAPC Gas- Absorptionskolonne für benetzte Oberflächen, computergesteuert.

INNOVATIVE SYSTEME

The studied absorption process corresponds to the oxygen-deoxygenated water system, where the oxygen comes from the air and the deoxygenated air is obtained through a desorption column, where a water current comes into contact with a nitrogen current.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The studied absorption process corresponds to the oxygen-deoxygenated water system, where the oxygen comes from the air and the deoxygenated air is obtained through a desorption column, where a water current comes into contact with a nitrogen current. This is an example of absorption controlled by liquid film, so that the liquid film mass transfer coefficient can be determined for different water flows.

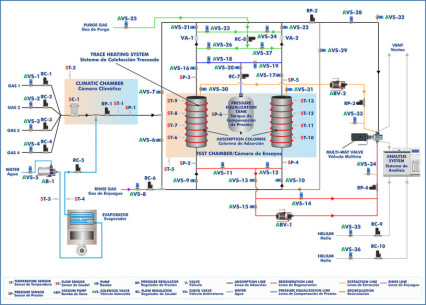

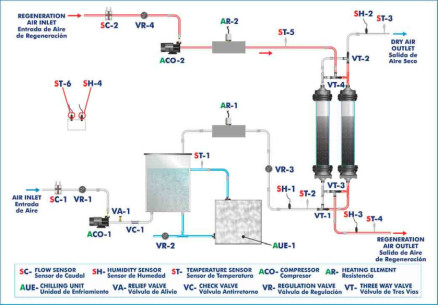

The unit consists of two glass columns, an absorption one and a desorption (deoxygenation) one, both of them supplied by two computer controlled pumps.

Air is introduced by a blower through the bottom of the column.

All the flow rates (air, water and nitrogen) are measured by sensors.

The absorption column has two overflows (one at the top and another at the bottom) connected to two membrane electrodes to measure the oxygen dissolved in water at the inlet and outlet of the column, together with an O2 measurement unit.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Absorption process study.

- Calculation of liquid film mass transfer coefficients.

- Study of the variation of the coefficient depending on mass flow rate.

- Variation of oxygen flow rate to determine power law relationship.

- Effect of water flow rate.

- Effect of oxygen flow rate.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the CAPC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the CAPC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Gas- Absorptionskolonne

Laboratory Scale Pressure Swing Adsorption Unit

Gerät für die Festbettadsorption, computergesteuert.

Computer Controlled Adsorptive Air Drying Unit

Abgaswaschanlage, computergesteuert.

Computer Controlled Unit to Study Flow through Packed Columns

Adsorptionsgerät, computergesteuert.

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen