TARC Gerät für die Umluft-Klimatisierung, computergesteuert (PC)

INNOVATIVE SYSTEME

The objective of Computer Controlled Recirculating Air Conditioning Unit, "TARC", is to introduce the student into the complex world of air conditioning systems, as well as studying and determining the optimal parameters for the operation of the unit in function of the environmental requirements (humidity, heat, temperature and cooling, etc.).

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

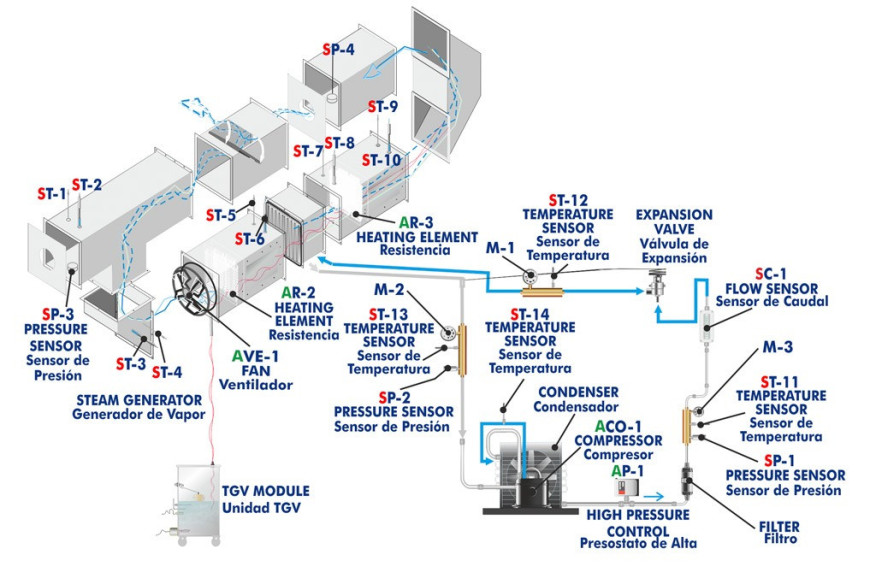

The Computer Controlled Recirculating Air Conditioning Unit, "TARC", has been designed to study both the changes in the air conditions and the refrigeration circuit. For that purpose, temperature sensors, pressure sensors and flow meters have been strategically located, allowing to study the refrigeration cycle and to quantify the capacity of the evaporation and condensation unit.

It can work with fresh air and recycled air.

The unit basically consists of a testing tunnel made of stainless steel, which has four windows (sight glasses). Inside there is an axial fan, two heating elements, one at the inlet of the evaporation unit of 2000 W and other at the outlet of 1000 W. There are also five hygrometers strategically located along the tunnel. These hygrometers consist of two temperature sensors (wet and dry bulb).

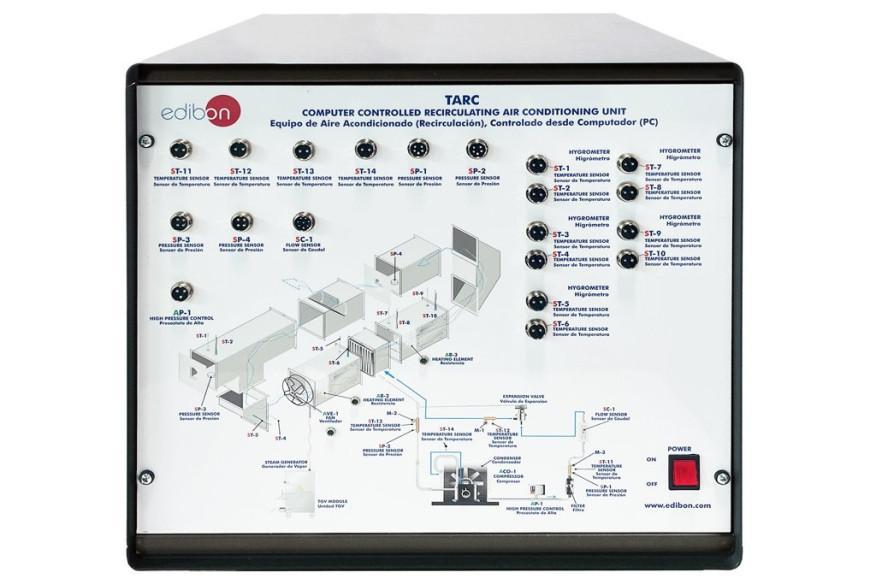

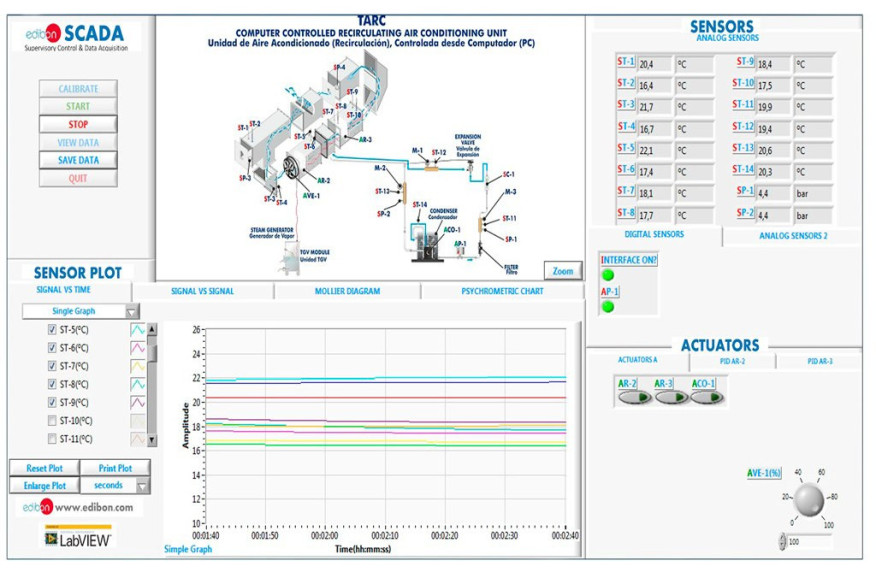

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Demonstration of the processes of air heating, cooling, humidification, de-humidification, recirculating and mixing.

- Efficiency determination of the preheating element.

- Preheating effect in an air conditioning installation.

- De-humidification process study.

- Mass balance in the evaporator.

- Energy balance in the evaporator.

- Re-heat effect.

- Experimental determination of the air specific heating capacity.

- Study of de-humidification in a recycling process.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Psychrometric chart.

- Usage of psychrometric chart.

- Determination of the airflow.

- Example of the air properties determination.

- Properties of the Refrigerant R-513a.

- Enthalpy-Pressure diagram for the refrigerant R-513a.

- Demonstration of recirculating and the adiabatic mixing of two air streams at different states.

- Obtaining of the steam generator efficiency curve.

- Energy balance in the steam generator.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TARC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TARC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

Gerät für eine Labor-Klimaanlage

Gerät für die Umluft-Klimatisierung

Gerät für Klimaanlage mit Klimakammer und Wasserkühler, computergesteuert (PC)

ERGÄNZENDE AUSRÜSTUNG

Gerät für die Produktion von Warmwasser und Heizsystemen, computergesteuert (PC)

Gerät für den Biomasseprozess, computergesteuert (PC)

Gerät für den Biomasseprozess

Gerät zur Untersuchung der Effizienz eines Heizsystems, computergesteuert (PC)

Trainingsgerät für Warmwasserbereiter

Wärmepumpe für verschiedene Quellen und Wärmetauscher

Fußbodenheizung und/oder Wärmequelle für Wärmepumpe

Luftheizung und/oder Luftwärmetauscher

Gerät für eine Labor-Klimaanlage, computergesteuert (PC)

Gerät für eine Labor-Klimaanlage

Gerät für die Umluft-Klimatisierung

Gerät für die Klimaanlage eines Autos, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen