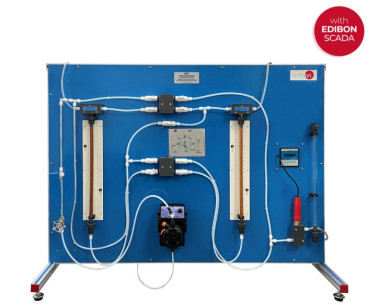

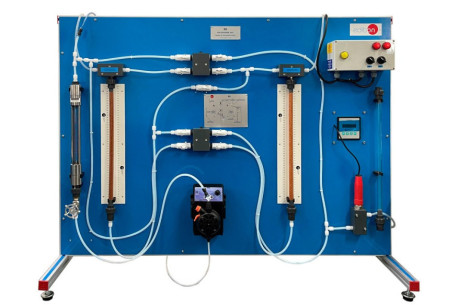

The Computer Controlled Corrosion Study Unit, "EECC", allows the corrosion simultaneous study up to eight corrosion cells. This unit allows to study several conditions that influence in the corrosion processes.

Each sample for the test is put in such away that unwanted secondary effects are eliminated.

The cells included a cover to adapt two test sheets, a reference electrode and a gas diffuser tube.

A salt bridge is included for the study and production of electrochemical cells.

It is possible connect the different samples to a computer controlled power supply to study the principle of sacrificial anodes.

The ambient air is introduced into the electrolyte solution with an computer controlled air pump. An air flowmeter is situated at the pump outlet to measure the air flow. There are several air control valves to adjust the air flow rate for each corrosion cell. It is also possible to feed other gases into the electrolyte solution using a gas flowmeter and several gas control valves.

The unit includes a pH sensor to study and compare the influence of the electrolyte solution on the corrosion processes.

The corrosion rate of a certain sample can be measured qualitatively by "visual observation", or quantitatively though "immersion test by initial and final weighing".

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookie-Präferenzen

Cookie-Präferenzen