EG5C Gerät für Geothermische Energie (niedrige Entalpie), computergesteuert (PC)

INNOVATIVE SYSTEME

The objective of the Computer Controlled Geothermal (low enthalpy) Energy Unit, "EG5C", designed by EDIBON, is to introduce the student into an increasingly leading renewable energy and, particularly, in the use of this energy for the climate control of buildings.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

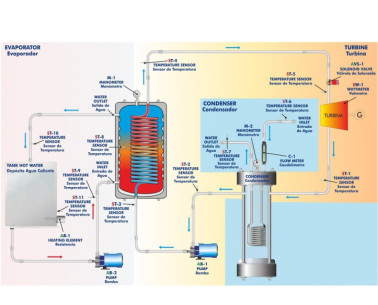

The Computer Controlled Geothermal (low enthalpy) Energy Unit, "EG5C", designed by EDIBON, consists of a cooling circuit, a small tank with pipes covered with water (bath) and a chilling unit (heat pump). The inside of the earth is simulated with them. There is another tank where the sanitary hot water heated bythe unit is stored.

The cooling circuit consists of a compressor, an air condenser/evaporator, and two water condensers/evaporators. The reason is that the unit has a 4 ways valve that can detect if it is summer or winter by the environmental conditions. According to this, it sends the refrigerant gas to one or another exchanger. So they are able to work as evaporators or condensers of the refrigerant liquid.

The ground is simulated by means of a small tank that covers some pipes and a heat pump.

The water of the tank is at a constant temperature, the same temperature that the earth has at 20 m of depth (15ºC [59ºF] approximately). This water goes to a bath, heating or cooling the water that flows through the pipes immersed in the bath.

Finally, there is a tank to store the water heated by the unit. It simulates the sanitary hot water of a house.

The unit has a cycle inversion valve, which is able to simulate winter and summer conditions, as it was mentioned before. Since the temperature of the earth at 20 m of depth is always 15ºC, this temperature will be higher than the environmental temperature in winter, therefore, the ground is used to heat (heating mode use). However, the environmental temperature in summer will be higher than 15ºC,so the ground’s water will be used to cool (refrigerating mode).

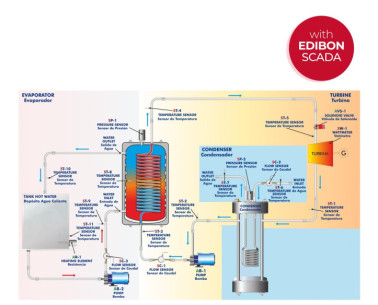

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of geothermal energy using a geothermal heat pump system for heating and/or cooling.

- Study of the system with different ground temperatures.

- Determination of the inlet power, produced heat and coefficient of performance, working in heating mode. Water-water heat pump.

- Determination of the inlet power, produced heat and coefficient of performance, working in cooling mode. Water-water heat pump.

- Determination of the inlet power and valuation of the air temperatures, working in heating mode. Water-air heat pump.

- Determination of the inlet power and valuation of the air temperature, working in cooling mode. Water-air heat pump.

- Preparation of performance curves of the heat pump, working in heating mode, with different inlet and outlet temperatures. Water-water heat pump.

- Preparation of performance curves of the heat pump, working in cooling mode, with different inlet and outlet temperatures. Water-water heat pump.

- Lay out of the steam compression cycle in a P-H diagram and comparison with the ideal cycle. Water-water heat pump. Heating mode.

- Lay out of the steam compression cycle in a P-H diagram and comparison with the ideal cycle. Water-air heat pump. Heating mode.

- Preparation of the performance curves of the heat pump based on the properties of the refrigerant and at different condensation and evaporation temperatures. Water-water heat pump. Heating mode.

- Preparation of the performance curves of the heat pump based on the properties of the refrigerant and at different condensation and evaporation temperatures. Water-water heat pump. Cooling mode.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EG5C unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EG5C unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

Gerät für Geothermische Energie (hohe Entalpie), computergesteuert (PC)

Gerät für Geothermische Energie (hohe Entalpie)

Gerät für Geothermische Energie mit Zwei-Brunnen-System, computergesteuert (PC)

ERGÄNZENDE AUSRÜSTUNG

Gerät für Geothermische Energie (hohe Entalpie), computergesteuert (PC)

Gerät für Geothermische Energie (hohe Entalpie)

Gerät für Geothermische Energie (niedrige Entalpie)

Gerät für Geothermische Energie mit Zwei-Brunnen-System, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen