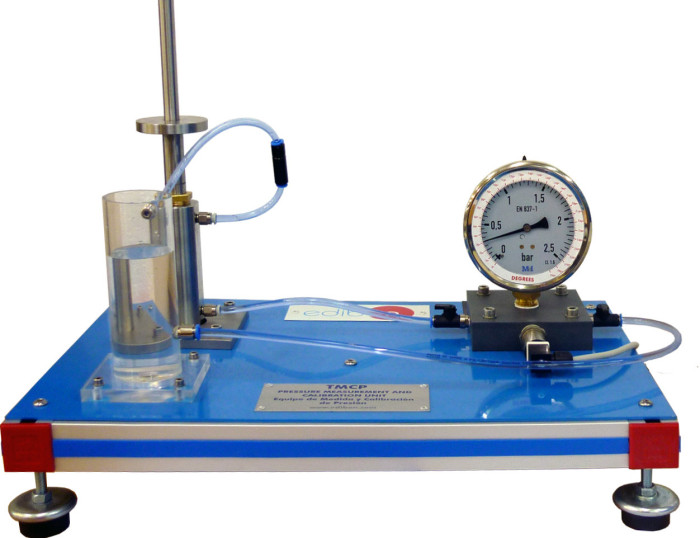

TMCP Gerät zur Druckmessung und -kalibrierung

INNOVATIVE SYSTEME

The Pressure Measurement and Calibration Unit, "TMCP", has been designed to study the concept of pressure and the different methods and techniques used to measure this variable.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Pressure Measurement and Calibration Unit, "TMCP", has been designed to study the concept of pressure and the different methods and techniques used to measure this variable.

The dead-weight calibrator consists of a cylinder in which interior a precision piston is fitted and slid. Different weights are added to generate inside the cylinder a certain amount of preset pressures.

The Bourdon manometer and the pressure sensor, which must be checked and calibrated, are connected to the cylinder through a flexible tube. Any possible leakage outside the piston is directed through the flexible tube towards a vessel, to which a check valve is fitted to prevent pressure drop in the manometer due to that leakage.

The Bourdon manometer includes a scale calibrated in degrees of rotation, apart from the usual pressure scale.

The pressure sensor generates an output voltage proportional to the applied pressure.

An electronic console with two digital displays that show the output of the pressure sensor (in Volts) and the conditioned reading in two engineering units. Besides the corresponding signals are sent to an I/O port for their acquisition via software in a computer (PC).

Software used to acquire data and to obtain the calibration curve (with slope and ordinate in the origin) both in function of the angular displacement of the needle and in function of the output voltage of the sensor.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the concept of pressure (force/area).

- Study of the function of a dead-weight pressure calibrator.

- Study of the concepts of measurement and calibration (gauge and absolute pressures, zero error, non-linearity, scale error, conversion of arbitrary scale into engineering units).

- Study of pressure scales.

- Study of the operation and characteristic behaviour of a Bourdon type manometer.

- Checking the readings of a Bourdon type manometer using a standard set of calibrated weights.

- Calibration of a Bourdon type manometer in engineering 2 units (kN/m² ).

- Calibration of a Bourdon type manometer in arbitrary units (angular displacement of needle).

- Study of the operation and characteristic behaviour of a pressure sensor.

- Calibration of a pressure sensor (output voltage of the sensor).

- Calibration of a pressure sensor and signal conditioning circuit in engineering units.

- Study of the sources of error in measuring and calibration (signal conditioning, manufacturing tolerances, display resolution, friction and backlash…).

ÄHNLICHE VERFÜGBARE GERÄTE

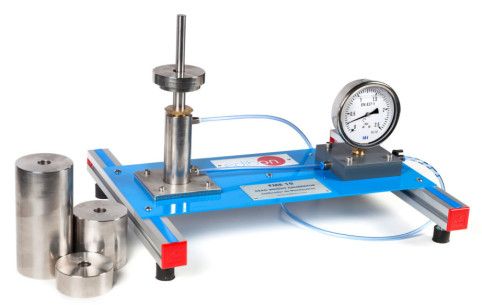

Präzisionsmanometer-Kalibrator

ERGÄNZENDE AUSRÜSTUNG

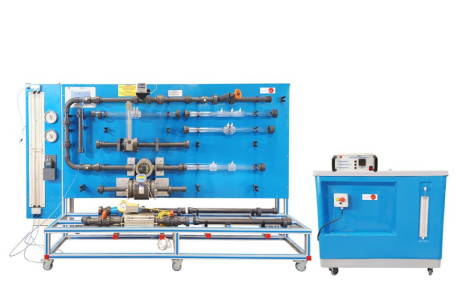

Vorführung von Durchflussmessgeräten

Gerät zur Druckmessung

Gerät: Kugelfallviskosimeter und Bestimmung des Widerstandskoeffizienten

Präzisionsmanometer-Kalibrator

System zur Kalibrierung von Drucksensoren

Manometer & Multimanometer (Verschiedene Typen):

Doppel-U-Rohr-Manometer

U-Rohr-Manometer

Schräg-Multimanometer mit 20 Messröhren, 250 mm Länge

Vertikales Multimanometer mit 8 Messröhren, 500 mm Länge

Vertikales Multimanometer mit 12 Messröhren, 500 mm Länge

Gerät mit 4 Bourdon-Manometern

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen