The Computer Controlled and Touch Screen UHT Unit, "AUHT/CTS", is a compact design and easy installation pilot plant that works as independent unit or as part of an integrated process finishing that allows for studying in depth the pasteurization process of products and the variables of the process.

The Computer Controlled and Touch Screen UHT Unit, "AUHT/CTS", follows a continuous process working mode and allows either for working with large batches or a more economical operation, since the maximum working capacity will be 15 l minimum.

It can operate with a great variety of products: beer, jellies, creams, sauces, etc. The unit is suitable to work with food since materials employed are appropriate for that use. A static stirrer is included to be used with high viscosity products.

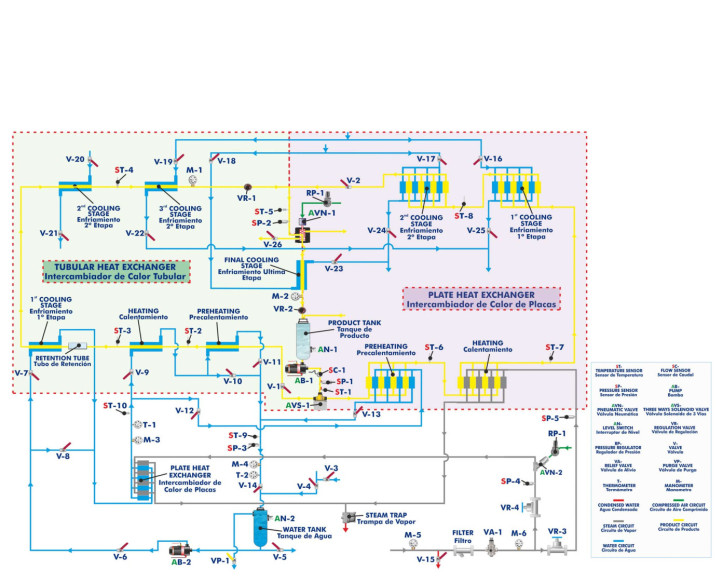

At the same time, the unit allows to compare the UHT process using tube or plate heat exchangers. Switching from one system to the other is done by means of a computer controlled pneumatic solenoid valve.

The product is introduced into the plant through a computer controlled speed pump.

The product preheating, heating and cooling stages can be done either in a tube heat exchanger or in a plate heat exchanger.

To guarantee that the product keeps a high temperature for several seconds to kills microorganisms, there is a retention tube to extend the retention time.

Finally, the unit also includes a bypass system to divert the product that has not been treated to the adjusted temperature. Computer controlled solenoid valves are used both in this system and to perform the heat exchanger selection.

The pilot plant allows for connecting several elements, such as a homogenizer, if necessary. There is a connection after the heating stage.

An additional plate exchanger is included to optimize the cooling of the product depending on the flow.

The instrumentation required to analyze all the important parameters of the process is also included: temperature, flow, level and pressure.

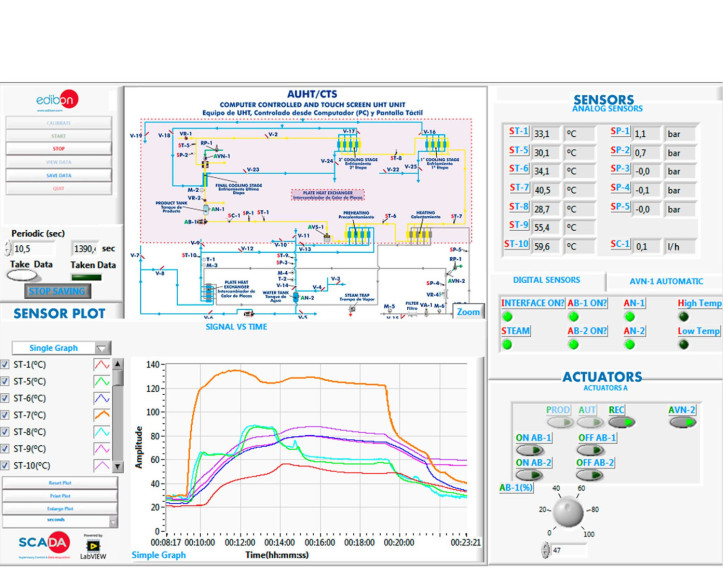

Additionally, the pilot plant includes a color 10 inches HMI display to visualize and activate the controls and indicators required: product supply pump and water pump, level sensors and lack of product or water warning alarm, solenoid valves, etc.

The software included with the unit allows real time data acquisition, allowing a manual operation of the plant stages.

This Computer Controlled and Touch Screen Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookie-Präferenzen

Cookie-Präferenzen