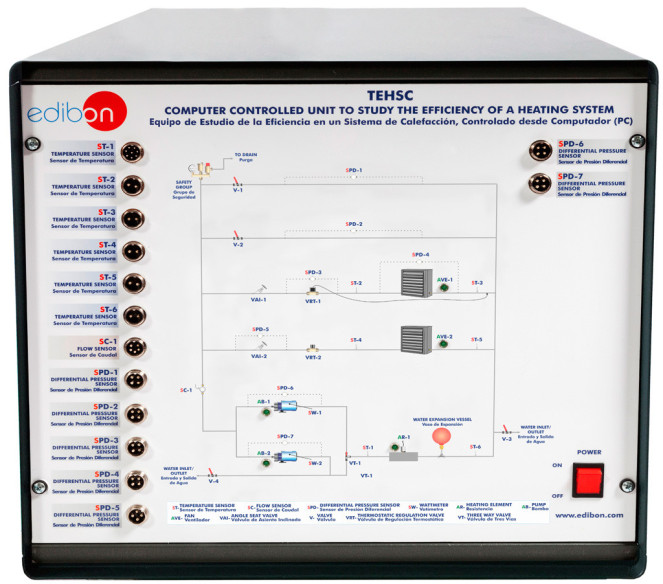

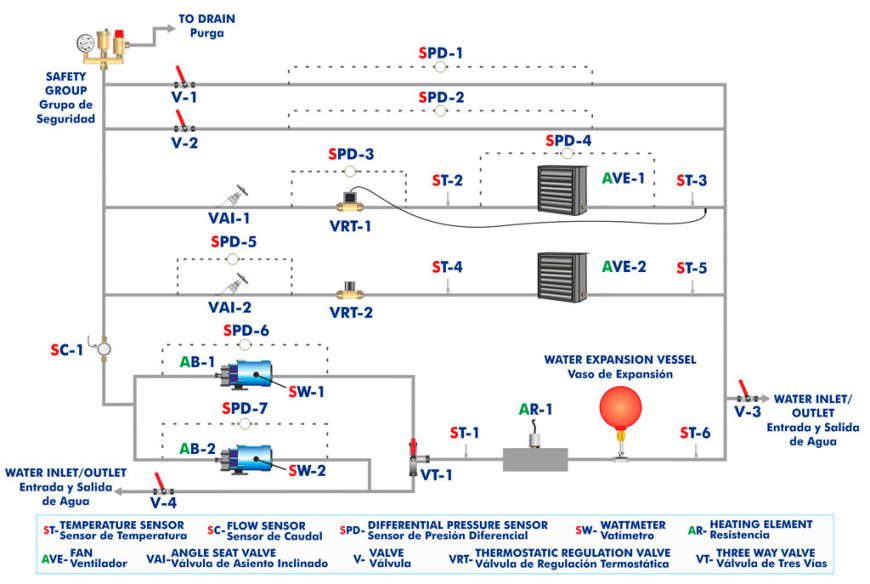

The Computer Controlled Unit to Study the Efficiency of a Heating System, "TEHSC",designed by EDIBON allows for studying and analyzing a closed heating system made upof pipes with different diameter and fittings normally used in real heating systems, with realsafety group (according to DIN 4751 standard). Allows to analyze its efficiency, includingthe operation, arrangement and understanding of its elements.

There are two computer controlled conventional circulation pumps to impel water alongthe system. The speed of one of them is adjustable, allowing a comparative study of bothpumps. There are two differential pressure sensors to study the pressure drops caused byeach pump.

The system includes a computer controlled heating element controlled by computer. It ischaracterized by step response, and by a two-point temperature control with referencevariables adjustment and hysteresis. Alternatively, it can be controlled by PID with set pointtemperature and adjustable parameters.

The unit distributes the hot water in several heating lines. In the lower lines, the unit includes two differential pressure sensors to studypressure drops in heating pipes of different diameter.

There are several valves in the upper lines of the unit for a comparative study and to determine pressure drops with two differential pressuresensors. These valves are two thermostatic valves with different thermostatic heads, which regulate in function of the room temperature andthe inner water temperature, and an angle seat valve.

In the upper lines there are also two convectors with computer controlled fan. The speed of one of them is adjustable, thus, apart fromemitting hot air, both devices can be compared. A differential pressure sensor allows the study of the pressure drops generated in aconventional convector.

Apart from studying the pressure drop generated in the components of the heating system, the unit includes a water flow sensor, two powersensors for the pumps and six temperature sensors distributed in key points of the system, allowing power flows calculation and efficiencyanalysis.

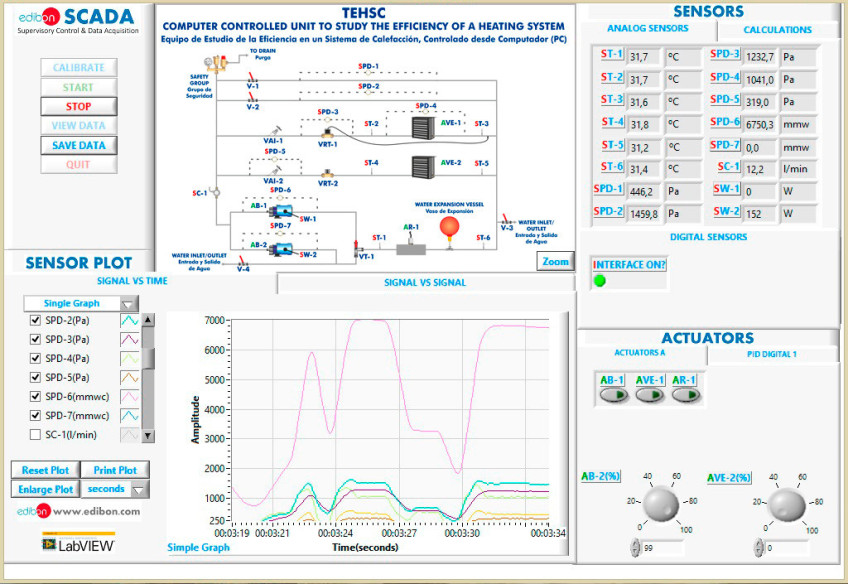

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

Cookie-Präferenzen

Cookie-Präferenzen