QRCC Katalytische Reaktoren, computergesteuert (PC)

INNOVATIVE SYSTEME

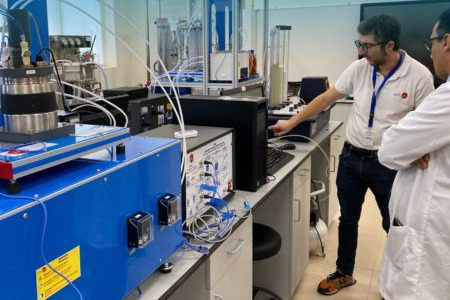

The Computer Controlled Catalytic Reactors, "QRCC", has been designed by EDIBON to perform the saccharose hydrolysis reaction in a continuous way by using catalytic fixed-bed reactors application.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Catalytic Reactors, "QRCC", has been designed by EDIBON to perform the saccharose hydrolysis reaction in a continuous way by using catalytic fixed-bed reactors application.

Saccharose hydrolysis is the industrial process to obtain glucose and fructose from saccharose. It is a reversible chemical reaction.

The "QRCC" unit consists of three fixed bed reactors. Two of them are fixed-bed reactors for chemical catalysis, composed of the same chemical catalyst, called ion exchange resins, but with different granulometry between them. The third reactor is a fixed-bed reactor for biological (enzymatic) catalysis, which is prepared for use with an immobilized enzyme through which we will pass our product, in this case sucrose, to proceed to its hydrolysis.

Saccharose hydrolysis is favoured with temperatures around 50 °C – 60 °C. For this purpose the reactors are jacketed and hot water is circulated through them. The temperature of this water is controlled by PID control through the control software.

Feeding saccharose to our reactors is done through a peristaltic pump which allows the regulation of speed through the control software. The resulting solution is pumped to the final-product flask. From this point on it will be analysed with a spectrophotometer that is adapted to "QRCC" unit interface.

As an optional supply, there is the possibility of acquiring the additional recommended element Computer Controlled Flow Injection Analysis (FIA) Unit, "QRCC-IF". This unit is a Flow Injection Analysis system, which is used to measure the conversion degree of the reaction of the saccharose hydrolysis in a continuous way.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Zubehör

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the principles of catalytic fixed-bed reactors.

- Effect of the variation in the particle’s size in the effectiveness of a fixed-bed reactor.

- Comparison of chemical and biological (enzymic) catalysis.

- Checking the influence on different variables (feed flow, temperature of reaction, reagents concentration) on the obtained final product.

- Spectrophotometer calibration.

- Using the spectrophotometer and product analysis.

- Study of the "FIA" Flow Injection Analysis technique and principles (with QRCC-IF optional accessory).

- Examination of the reproducibility and sensitivity of the "FIA" analysis method as a function of the flow rate and sample concentration (with QRCC-IF optional accessory).

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Studies of steady and unsteady state catalysis.

- Flow characterisation in a fixed-bed.

- Mass balances.

- Determination of steady state and unsteady state kinetics of a catalytic fixed-bed reactor.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QRCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QRCC unit process.

- Several other exercises can be done and designed by the user

ÄHNLICHE VERFÜGBARE GERÄTE

Katalytische Reaktoren

ERGÄNZENDE AUSRÜSTUNG

Schulungsanlage für chemische Reaktoren, computergesteuert (PC)

Basis- und Serviceeinheit für QRQC

Isothermer Reaktor mit Rührwerk

Isothermer Reaktor mit Rührwerk und Destillation

Turbinenreaktor

Rührkesselreaktoren in Serie

Adiabatischer und isothermer Reaktor

Chemische Reaktoren, computergesteuert (PC)

Basis- und Serviceeinheit für QRC

Kontinuierlicher Rührkesselreaktor für QRC, computergesteuert (PC)

Turbinenreaktor für QRC, computergesteuert (PC)

Diskontinuierlicher Reaktor für QRC, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen