At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-CP Lernfabrik-Prozesskontrolle

INNOVATIVE SYSTEME

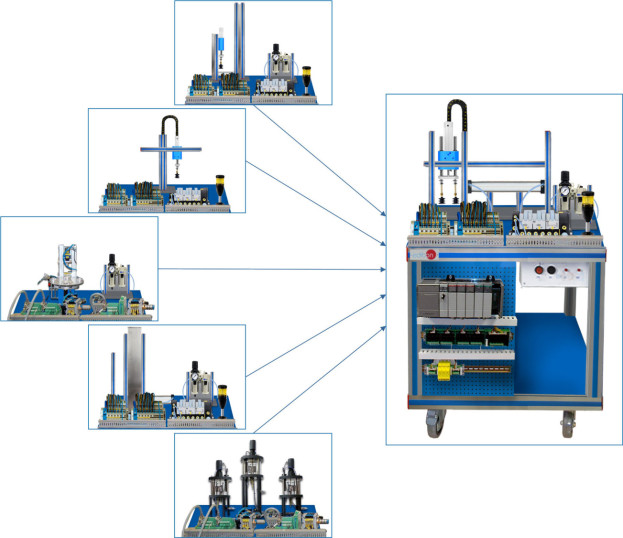

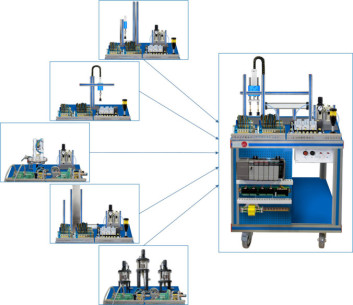

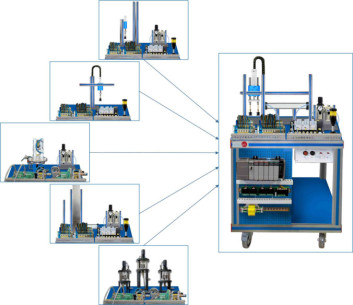

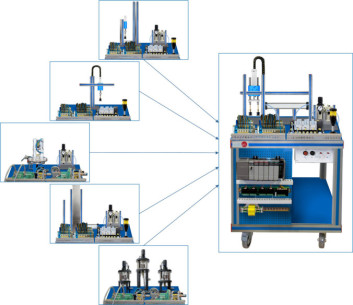

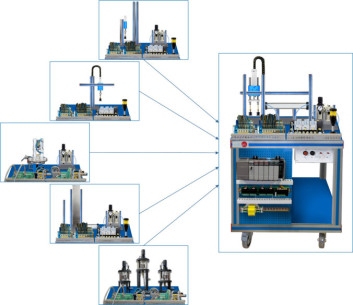

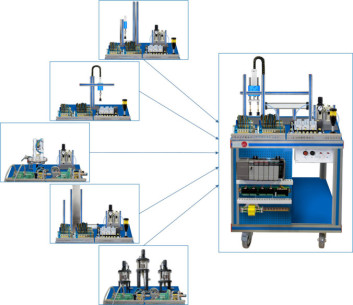

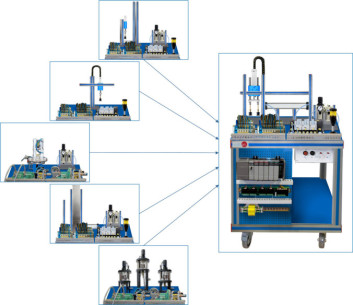

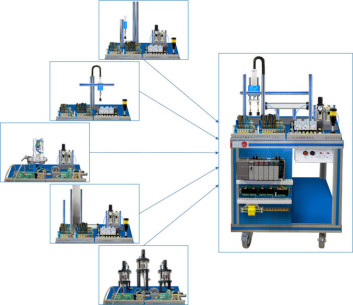

The "AE-PLC-CP" is a process control workstation commanded by a PLC that coordinates the work of 3 industrial controllers that regulates in parallel the level, flow rate, temperature and pressure processes.

Erweiterungen

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The "AE-PLC-CP" is a process control workstation commanded by a PLC that coordinates the work of 3 industrial controllers that regulates in parallel the level, flow rate, temperature and pressure processes.

The "AE-PLC-CP" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: emergency stop push button switch, start/stop button, reset button, light indicator to show the state of the workstation, etc.

- The pneumatic circuit: contains the required such as solenoid valves, air filters, air regulators, etc. to assure the appropriate operation of the workstation.

- The workstation: is composed by real components used by the industrial processes controllers systems such as: industrial controllers, pumping system, pressure sensors, temperature sensors, etc.

The "AE-PLC-CP" workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at the "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Study of the sensor detection.

- Manual control of tank level.

- Automatic control of tank level with industrial controllers.

- Manual control of temperature.

- Automatic control of temperature with industrial controllers.

- Manual control of tank pressure.

- Automatic control of tank pressure with industrial controllers.

- Manual control of flow rate.

- Automatic control of flow rate with industrial controllers.

- Study of a complete automatic process control workstation.

- Study the faults inserted in the process with the fault generation module.

ÄHNLICHE VERFÜGBARE GERÄTE

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-FT

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MS

Lernfabrik zum Mischen

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-PHD

Lernfabrik zum Stanzen

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-FS

Lernfabrik zur Befüllung

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-CRS

Lernfabrik-Verkorkung

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-APB

Lernfabrik-Dosenöffnungsstation

The "AE-PLC-APB" is a bottles opening system commanded by a PLC. The unit is equipped with different containers and a retention system based on a cylinder, in order to allow the Robotic Arm Workstation "AE-BR" or the SCARA Arm Workstation "AE-SCA"...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-M

Lernfabrik zur Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-P

Lernfabrik zum automatischen Pressen

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-AT

Lernfabrik-Automatische Schraubstation

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MEMB

Lernfabrik-Abfüllung

The "AE-PLC-MEMB" is a bottling workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-MEMB" transport the input bottles, to the filling area. In this zone, the "AE-PLC-MEMB" fills...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MET

Lernfabrik-Etikettierung

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-ST

Lernfabrik zum Bohren

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-SMOLD

Lernfabrik zum Formen

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-SCOR

Lernfabrik-Schneidestation

The "AE-PLC-SCOR" is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine simulate the process.The "AE-PLC-SCOR"...

ERGÄNZENDE AUSRÜSTUNG

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-M

Lernfabrik zur Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-P

Lernfabrik zum automatischen Pressen

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-AT

Lernfabrik-Automatische Schraubstation

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MEMB

Lernfabrik-Abfüllung

The "AE-PLC-MEMB" is a bottling workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-MEMB" transport the input bottles, to the filling area. In this zone, the "AE-PLC-MEMB" fills...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MET

Lernfabrik-Etikettierung

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-ST

Lernfabrik zum Bohren

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-SMOLD

Lernfabrik zum Formen

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-SCOR

Lernfabrik-Schneidestation

The "AE-PLC-SCOR" is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine simulate the process.The "AE-PLC-SCOR"...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-FT

Lernfabrik-Filtration

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-MS

Lernfabrik zum Mischen

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-PHD

Lernfabrik zum Stanzen

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- PROCESS WORKSTATION-ANWENDUNGEN

AE-PLC-FS

Lernfabrik zur Befüllung

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen