At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-VS Lernfabrik-Qualitätskontrolle

INNOVATIVE SYSTEME

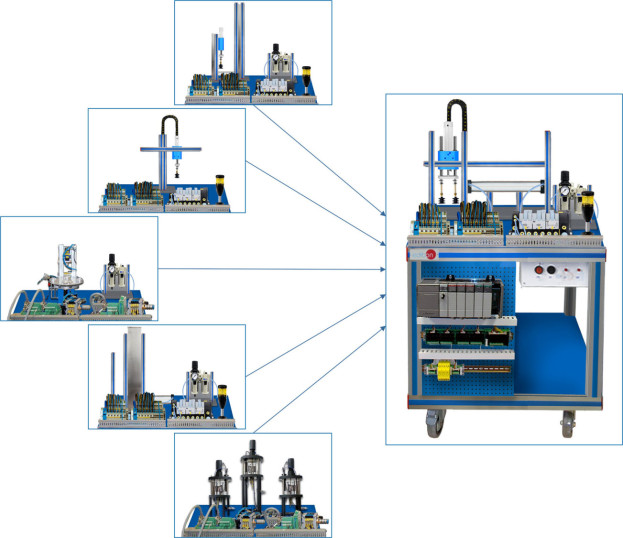

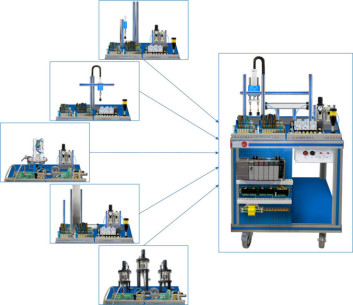

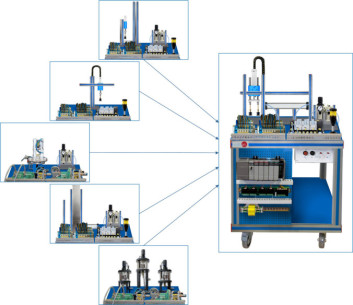

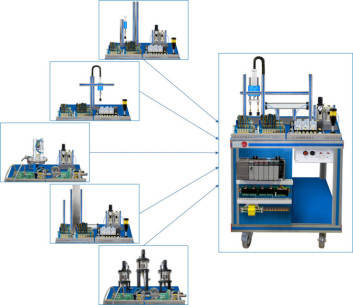

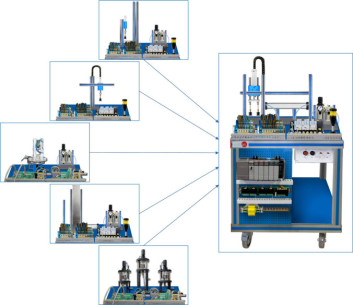

The Quality Control Workstation with Vision System, "AE-PLC-VS", has been designed by EDIBON to study how manage a quality control system using a color camera. The "AE-PLC-VS" includes industrial components to conform the system such as PLCs, pneumatic components, industrial sensors, etc.

Erweiterungen

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The "AE-PLC-VS" is a quality control system commanded by a PLC. The "AE-PLC-VS" is equipped with a color camera that identifies the pieces on a conveyor belt. Depending on different specification, the system separates the corresponding pieces using a pneumatic slide gate.

The "AE-PLC-VS" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: emergency stop push button switch, start/stop button, reset button, light indicator to show the state of the workstation, etc.

- The pneumatic circuit: contains the required solenoid valves, filters and regulators to assure the correct working and safety of the unit.

- The workstation: is composed of real components used by the industrial automatic conveyor systems such as: capacitive sensors, limit switch sensors, position sensor, etc.

The "AE-PLC-VS" workstation can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at the "60.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS" area.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Introduction to flexible manufacturing system, identification of unit components.

- Configuration of a pneumatic application.

- Manual pieces verification process with an industrial camera.

- Automatic pieces verification process with an industrial camera.

- Optimizing the automatic pieces verification process with an industrial camera.

ÄHNLICHE VERFÜGBARE GERÄTE

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CF

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places. The "AE-PLC-CF" workstation is designed as a modular system...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SLB

Lernfabrik zur Kugelauswahl

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes....

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-RFID

Lernfabrik-RFID-Identifikation

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SIP

Lernfabrik-Teile-Identifikation

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CPD

Anwendung für eine Station zur Klassifizierung fehlerhafter Teile

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

ERGÄNZENDE AUSRÜSTUNG

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SIP

Lernfabrik-Teile-Identifikation

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CF

Lernfabrik-Sortierstation

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places. The "AE-PLC-CF" workstation is designed as a modular system...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-SLB

Lernfabrik zur Kugelauswahl

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes....

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-RFID

Lernfabrik-RFID-Identifikation

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- TEILE IDENTIFIKATION ARBEITSPLATZANWENDUNGEN

AE-PLC-CPD

Anwendung für eine Station zur Klassifizierung fehlerhafter Teile

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen