CE00 Pilotanlagen für die Getreideproduktion, Computergesteuert (PC) und Touchscreen

INNOVATIVE SYSTEME

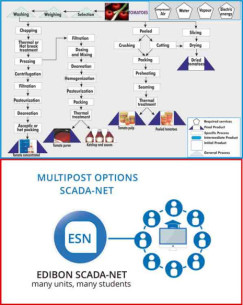

The Computer Controlled and Touch Screen Pilot Plants for the Production of Cereals, "CE00", is a pilot plant that is capable of carrying out the main processes present in the treatment of cereal grain, including grain milling, bread and pasta making, and cereal malting.

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled and Touch Screen Pilot Plants for the Production of Cereals, "CE00", is a pilot plant that is capable of carrying out the main processes present in the treatment of cereal grain, including grain milling, bread and pasta making, and cereal malting.

The "CE00" pilot plants consist of:

- CE00/MF. Pilot Plant for Milling and Flour Production. Main line starts from the cereal grain. This grain is fed to the milling stage where a stone mill is used. Later on, a sifter is used to separate the flour according to particle size. Finally, a pneumatic system is used for the suction and transport of the flour, which includes a cyclone to facilitate its transport.

- CE00/B. Pilot Plant for the Production of Bread. The flour is fed to a dough mixer in which the dough is created by adding water and yeast. Afterwards, the division process is carried out so that the dough is split in identical pieces and then left to rest, in ambient conditions or in cameras in which the conditions are controlled. The next step is the shaping of the dough. Finally, the dough is placed on trays and baked. There is the possibility that the forming process can be done mechanically.

- CE00/P. Pilot Plant for the Production of Pasta. The other production line leads to the elaboration of dough using the flour that comes from the milling line. The flour is fed to the mixer to form the dough. Afterwards, the dough is extruded to aim the desired shape by passing it through different molds. Finally, it is possible to dry the fresh dough to promote its conservation and reduce its weight.

- CE00/MA. Pilot Plant for Cereal Malting. Is a pilot scale plant that includes all the industrial stages for malt production. This plant includes a steeping tank, a germinator, a dryer-roaster and a deculmer. In addition, it includes the auxiliary equipment necessary to carry out the operation in a comfortable and safe way.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the conditions of wheat milling.

- Study of the relation between the final size of the flour grain and the milling stones distance.

- Study of the milling of different types of cereals.

- Study of the separation of solids in a sifter.

- Study of the separation of the flour according to the type of cereal.

- Study of the separation speed as a function of the sieve rotation speed.

- Study of a pneumatic system for transporting solids.

- Study of the kneading process.

- Study of the influence of the flour-water-yeast ratio in bread making.

- Study of the influence of kneading time.

- Study of the time and conditions of fermentation in the elaboration of bread.

- Study of the process of weighting and forming.

- Calculation of the error produced in the division and weighing of the dough.

- Study of the influence of the time of fermentation in the dough.

- Study of the forming process in bread doughs.

- Making of bread loafs of different shapes.

- Influence of the separation of the lamination rolls.

- Influence of the baking temperature on the resulting bread.

- Influence of the baking time on the resulting bread.

- Influence of the heating ramp on the resulting bread.

- Variation of the baking conditions according to the type of bread.

- Study of the wheat pasta extrusion process.

- Study of the pressure in the extrusion process.

- Elaboration of fresh pasta with different molds.

- Differences between the elaboration of long and short fresh pasta.

- Study of the drying process of pastes.

- Determination of the drying time.

- Differences in the drying process between several types of pasta.

- Evolution of the temperature and the humidity in the drying process.

- Study of the barley steeping process.

- Influence of temperature on water absorption.

- Influence of the pH in the humidification process.

- Study of the production of CO2 in the process of steeping and germination.

- Study of the influence of the aeration flow in the steeping process.

- Evolution of humidity during the steeping stage.

- Study of the operation of an auger transport system.

- Study of the influence of temperature on the germination process.

- Study the influence of humidity on the germination process.

- Study of the influence of the stirring in the process of germination.

- Study of the influence of the air flow on the germination process.

- Study of the operation of a heat pump.

- Study of the operation of a cereal dryer.

- Study of the drying and toasting times of malt.

- Study of the temperature evolution in the drying process.

- tudy of the influence of temperature on the malt during the roasting phase. Production of pale, roasted and dark malts.

- Study of the influence of gas recirculation in the dryer.

- Study of the deculmer process.

- Calculation of the percentage of culm in the malt.

ÄHNLICHE VERFÜGBARE GERÄTE

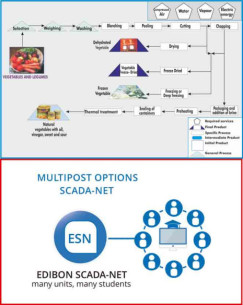

Pilotanlage für Gemüse und Hülsenfrüchte, Computergesteuert (PC) und Touchscreen

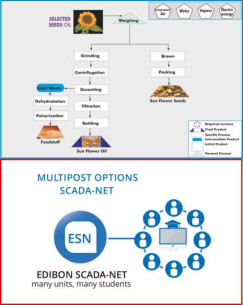

Pilotanlagen für die Ölproduktion, Computergesteuert (PC) und Touchscreen

Pilotanlage für die Weintraubenverarbeitung, Computergesteuert (PC) und Touchscreen

ERGÄNZENDE AUSRÜSTUNG

Gerät für Lösungsmittel-Extraktion und Desolventisierung, computergesteuert (PC)

Gerät zur Hydrierung, computergesteuert (PC)

Gerät zur Desodorierung, Computergesteuert (PC)

Didaktischer Kühlbehälter, computergesteuert (PC)

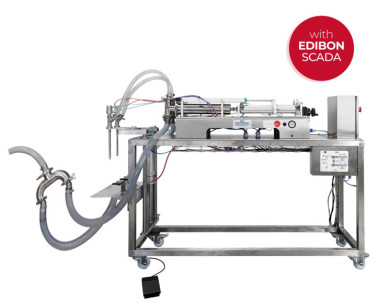

Didaktisches Gerät für die Abfüllung von Flüssigkeiten, computergesteuert (PC)

Didaktisches Gerät für die Verpackung von Feststoffen, computergesteuert (PC)

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Anlage zur kontinuierlichen Herstellung von Öl, computergesteuert (PC)

Pilotanlagen für Fleischproduktion, Computergesteuert (PC) und Touchscreen

Pilotanlage für Gemüse und Hülsenfrüchte, Computergesteuert (PC) und Touchscreen

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen