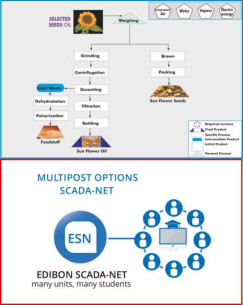

AC00 Pilotanlagen für die Ölproduktion, Computergesteuert (PC) und Touchscreen

INNOVATIVE SYSTEME

The Computer Controlled and Touch Screen Pilot Plants for the Production of Oil , "AC00", is a pilot plant able to carry out the main processes present in the elaboration of virgin olive oil.

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled and Touch Screen Pilot Plants for the Production of Oil , "AC00", is a pilot plant able to carry out the main processes present in the elaboration of virgin olive oil.

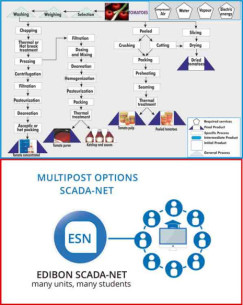

The "AC00" pilot plant incorporates a production line analogous to the large oil mills that produce olive oil industrially.

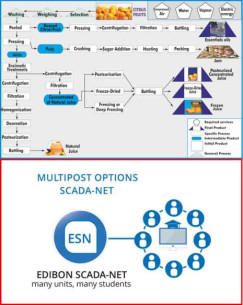

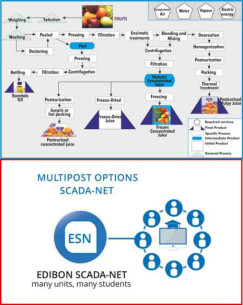

- OWLR/CTS. Computer Controlled and Touch Screen Olive Washing Machine and Leaf Remover: The first step in the treatment of the olives is the washing and removing of leaves, dust and other impurities.

- PACC. Computer Controlled Continuous Cycle Oil Production Plant: From the washer, the olives are fed to the knife mill, where the olives are milled to extract a paste from which, later on, the oily phase will be extracted.

- OCPF/CTS. Computer Controlled and Touch Screen Oil Collector with Plate Filter: From the mill, the paste produced is taken to the malaxer in which the emulsion is broken and the drops of oil are grouped together thanks to the constant temperature and the slight stirring.

- Finally, the phases formed in the malaxer are separated due to their different density using a decanter (centrifugal separator), in which the pomace and the water are obtained on the one hand, and the oil on the other.

- EDLC. Computer Controlled Liquid Packaging Teaching Unit: It is a liquid and semi-dense products dosing machine based on dose delivery through a pneumatically-operated cylinder.

These units are supplied with EDIBON’s own designed SCADA + PLCHMI (system composed by an interface including PLC modules such as CPU, digital I/O module, analog I/O module, communication module, etc. and a control box with HMI display) to control the whole process and all the parameters that are involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the washing flow.

- Study of the leaf-removing and washing efficiency.

- Milling speed study.

- Study of the temperature at the malaxer.

- Study of the agitation in the malaxer.

- Study of the speed of rotation in the decanter.

- Study of the pressure loss in the plate filter.

- Study of the efficiency of the filtration.

- Analysis of all phases of the product transformation, from reception to packaging.

- Qualitative evaluation of the finished product as function of the productive operations performed.

- Experimentation on the efficiency of the different chemical products used for the preservation process.

- Organization of procedures for continuous quality control of the production operations.

- Execution of procedures for disinfection and sanification of the equipment.

- Evaluation of technical, legal and administrative aspects concerning food adulteration.

- Manual and computer control operation.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. Each unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc. in real time.

- Each unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- Each unit can be used for doing applied research.

- Each unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Visualization of all the sensors values used in the AC00 pilot plant process.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

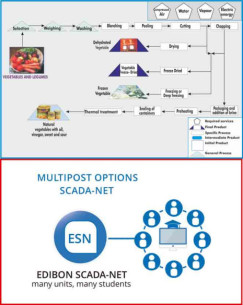

Pilotanlage für Gemüse und Hülsenfrüchte, Computergesteuert (PC) und Touchscreen

Pilotanlagen für die Getreideproduktion, Computergesteuert (PC) und Touchscreen

ERGÄNZENDE AUSRÜSTUNG

Fortschrittliches Gerät zur Desodorierung, Computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen