The minimum supply consists of two main elements: the TRAMC Unit Base, "TRAMC-UB", and at least one of the required elements described below.

The models are interconnected by special refrigerant hoses.

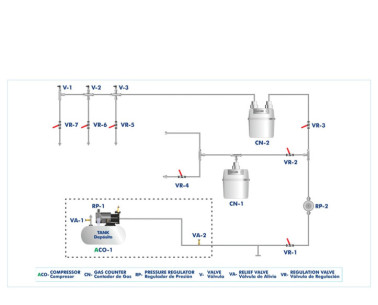

The main components of the TRAMC Unit Base, "TRAMC-UB", are compressor, condenser, refrigerant receiver and accessories to complement the refrigeration cycle. They are arranged in a clear and visible way to facilitate the understanding of the thermodynamic cycle.

The SCADA software, developed by EDIBON, has a data acquisition and control system that enables to automate the unit and to perform and assess all the practical exercises quickly, as well as to represent all the measured and calculated magnitudes in real time.

The measurements of the experiment are recorded in function of time and the generation of file compatible with spreadsheet applications via software. The temperatures and pressures existing in the system are recorded by sensors. Besides, the thermodynamic cycle can be represented in p-h and h-x diagrams.

The TRAMC/4 model is part of the "TRAMC" training system for refrigeration and air conditioning engineering. The model, attached to the base unit by refrigeration hoses and fastened to the frame by bolts, is a full air conditioning system is created for the air cooler that allows for the explanation of the operation of an air conditioning system, the principals components and the recirculating air and outer air operating mode.

The purpose of room air conditioning is to shape the room climate in accordance with the requirements of people or sensitive goods.

It contains a fan with transparent front part, that recirculates the air between the two air ducts . The top air duct serves as climatic chamber whilst the bottom air duct contains the air cooler, two electric air heaters and a steam humidifier. A motorized butterfly valve in the top air duct allows a change between outer air and recirculating operation.

Depending on the combination of the different elements, the air can be cooled, heated, humidified or dehumidified.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The TRAMC Unit Base (TRAMC-UB) + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookie-Präferenzen

Cookie-Präferenzen