TCCC Gerät für Wärmeleitung, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Heat Conduction Unit, "TCCC", consists of two modules electrically heated.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Heat Conduction Unit, "TCCC", consists of two modules electrically heated.

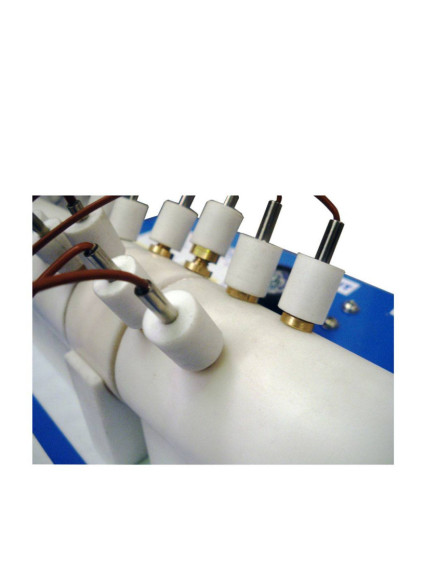

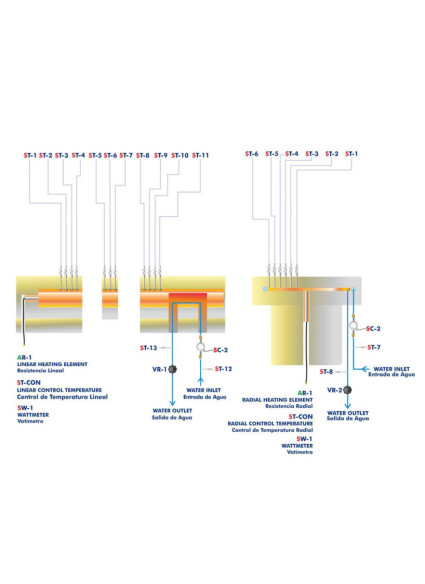

One of the modules is provided of a cylindrical metal bar for the realization of a series of experiments of linear heat conduction. While the ther one consists of a metallic disk that allows studying the radial heat conduction. Both modules are provided with a series of takings for the connection of a series of temperature sensors "T" type (high precision). To maintain the gradient of constant temperature, on a side of the modules, a cooling system has been inserted by circulating water.

The instrumentation provided with the unit allows making the measuring of the temperature and the electric power given to the heating element. For the control of the given energy it has a control circuit that allows the variation from 0 to 100 % of the maximum heating element power, through the computer.

The linear heat conduction module is supplied with interchangeable samples of different materials, different diameters and different insulating materials that allow to demonstrate the area effects, the conductivity and the combinations in series in the heat transfer process.

The radial heat conduction module consists of a disk with a refrigeration system in its end. In this module, there are six temperature takings placed along its radius. The heating element is placed exactly in its central point surrounded by an effective insulating material.

The two modules incorporate a water regulation valve, which allows the flow of cooling water to be varied, a water flow sensor, and temperature sensors at the water inlet and outlet.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Conduction through a simple bar.

- Conduction through a compound bar.

- Determination of the thermal conductivity k of different materials (conductors and insulators).

- The thermal conductivity properties of insulators may be found by inserting paper or other elements between the heating and cooling sections.

- Insulation effect.

- Determination of the thermal contact resistance Rtc .

- Effect of the crossing sectional area.

- Radial conduction.

- Understanding the use of the Fourier equation in determining rate of heat flow through solid materials.

- Observing unsteady-state conduction.

- Sensors calibration

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TCCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TCCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

Radiales Wärmeleitungsmodul für TSTCC

Lineares Wärmeleitungsmodul für TSTCB

Radiales Wärmeleitungsmodul für TSTCB

ERGÄNZENDE AUSRÜSTUNG

Serie zur Untersuchung des Wärmeübergangs, computergesteuert (PC)

Steuer-Interface-Box für TSTCC (gemeinsam für alle Module des Typs "TXC")

Lineares Wärmeleitungsmodul für TSTCC

Radiales Wärmeleitungsmodul für TSTCC

Wärmeübertragungsmodul durch Strahlung für TSTCC

Kombiniertes Modul für freie und erzwungene Konvektion und Strahlung für TSTCC

Wärmeübertragungsmodul auf erweiterter Oberfläche für TSTCC

Strahlungsfehlermodul in Temperaturmessungen für TSTCC

Nichtstationäres Wärmeübertragungsmodul für TSTCC

Flüssigkeits- und Gaswärmeleitfähigkeitsmodul für TSTCC

Wärmeübertragungsmodul für freie und erzwungene Konvektion für TSTCC

Wärmeübertragungsmodul in drei Achsen für TSTCC

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen