The Advanced Computer Controlled Continuous Distillation Unit "UDCC/A" is an installation that allows the study of fractional distillation using a packed column which is able to operate with different packings.

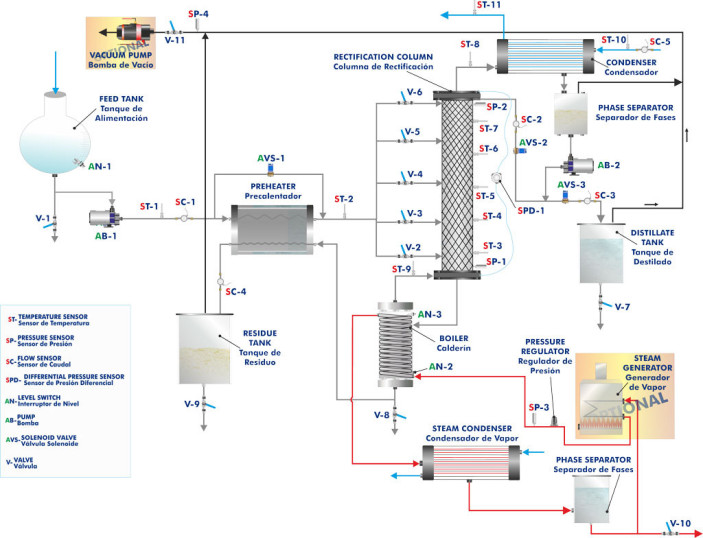

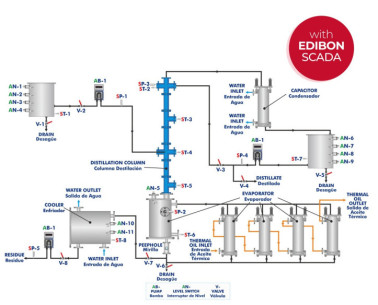

There is a feeding system that consists of a storage tank and a centrifugal pump. The feed is preheated before entering the column by going through a heat recovery system, in which the waste heat from the residue is used to take the feed stream to the desired temperature. The separation takes place in the column obtaining a steam current at the top, rich in the most volatile component, this steam is conducted to a condenser and then separated into two currents: a current that is returned to the column (reflux) and another current that is taken to the distillate tank. It is possible to regulate the reflux ratio by using a solenoid valve. On the other hand, at the bottom of the column a liquid stream falls into the boiler, in this unit, part of this liquid is evaporated and returned to the column as a vapour, and the other part of the liquid is taken to the preheater to be cooled down and then conducted to the residue tank.

The pilot plant includes a vacuum system that allows operation at reduced pressure. In this way it is possible to work with compounds with a low flash point. In addition, one of the configurations allows to work with certain concentrations of mineral acids in the feed.

Moreover, there is a process heat system that allows the introduction of pressurized steam as a heat contribution to the boilers and a cooling water system for the condenser and heat recovery.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookie preferences

Cookie preferences