The Bioethanol Process Unit (EBEB) has been designed to study and control the bioethanol production process on a laboratory scale. This unit allows to monitor and examine all the important processes, from liquefaction and saccharification of the raw materials, to the conversion of sugar into ethanol and distillation.

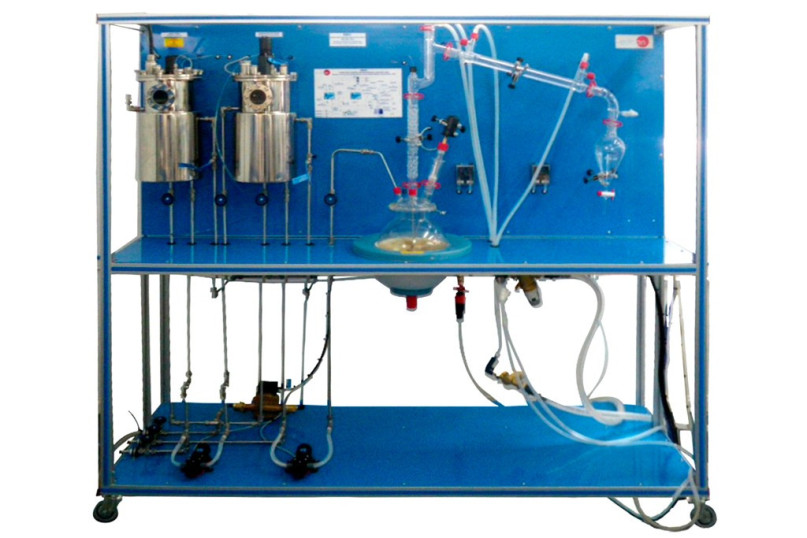

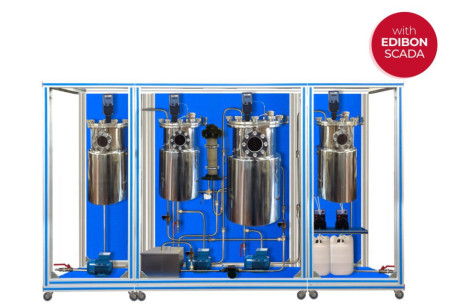

The unit consists of three main components: a mash tank, a fermentation tank and a distillation unit.

All vessels, valves and other accessories in contact with the process materials (except the distillation unit) are made of stainless steel. The distillation unit is made of borosilicate glass. Sight glasses are made of Neoceram glass.

The mash tank includes an inlet at its upper cover for filling water, starch and enzymes. Its base is slightly inclined towards a port for draining the solution or pumping it into the fermentation tank. During the mashing process the starch of the raw materials is turned into glucose. The addition of the alpha-amylase enzyme enables the liquefaction of the starch slurry. Subsequently, saccharification starts by adding the glucoamylase enzyme. A temperature sensor and a pH meter measure the properties of the mixture in the tank. The pH value is adjusted by adding acid and base.

After saccharification the mash is pumped into the fermentation tank. The fermentation tank base is inclined slightly towards a port for draining the solution or pumping it into the distillation unit. The fermentation process takes place after adding yeast, producing ethanol and CO2. A temperature sensor and a CO2 meter measure the properties of the mixture and the concentration of CO2 in the tank.

Both tanks are heated indirectly with hot water through a jacket and stirred constantly. Besides, they are equipped with a sight glass so that the process can be observed and monitored. Two temperature sensors are located at the outlet of the tanks' jacket.

The mash tank and the fermentation tank are thermally controlled by hot water, which is heated by a system consisting of a thermostatic bath and a pump. An additional temperature sensor is located in the thermostatic bath.

After the fermentation process, the preparation is pumped into the distillation unit. It contains a heating mantle, a stirrer, a distillation column, a cold finger (dephlegmator), a condenser and a decanting funnel. Four temperature sensors are located at different points of the distillation unit.

Cookie preferences

Cookie preferences