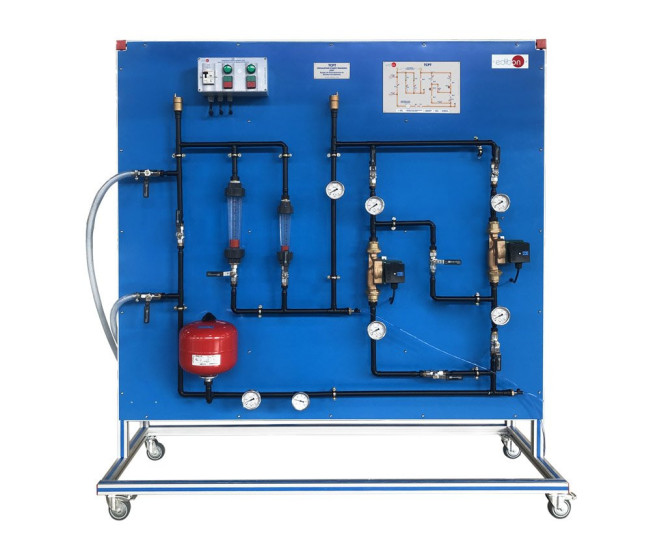

The Circulating Pumps Training Unit, "TCPT", designed by EDIBON, is an advanced tool designed to facilitate the study and understanding of the operation of circulation pumps in heating systems and sanitary techniques. This unit allows experimenting with series and parallel configurations, providing a clear view of how each arrangement affects the hydraulic performance of the system. This unit allows simulating and analyzing real heating system situations, which makes it an essential resource for hands-on learning.

The unit consists of a closed circuit that includes two circulating pumps that can operate either in series or in parallel. This versatility allows users to study the differences in pressure and flow generated under each configuration, which is essential for optimizing the design and maintenance of real-life heating systems. Thanks to the ease of switching between configurations via strategically placed ball valves, multiple experiments can be performed quickly and efficiently.

The "TCPT" also gives users the ability to delve deeper into key concepts such as pressure, flow rate and system stability. Thanks to pressure gauges located at representative points in the circuit and flow meters that accurately measure water flow, it is possible to observe first-hand how these parameters vary at different points in the system. The unit is equipped with an expansion vessel, which is crucial for maintaining a constant pressure, ensuring that the system operates safely and efficiently.

Circulation pumps are the heart of the system, driving the water through the circuit. Depending on whether they are connected in series or in parallel, users can observe how pressure and flow rate vary. In the series configuration, water flows through both pumps consecutively, which increases the overall system pressure, but maintains the same flow rate. In the parallel configuration, the water is split and passes through both pumps simultaneously, which increases the total flow, but keeps the pressure constant. This ability to switch between the two configurations allows experimenting with different parameters and understanding how the system behaves in real situations.

The unit includes ball valves that control the water flow and allow easy switching between configurations. The unit provides accurate, real-time data. Pressure gauges monitor the pressure at different points in the system, while flow meters provide a reading of the volume of water flowing through the circuit.

Cookie preferences

Cookie preferences