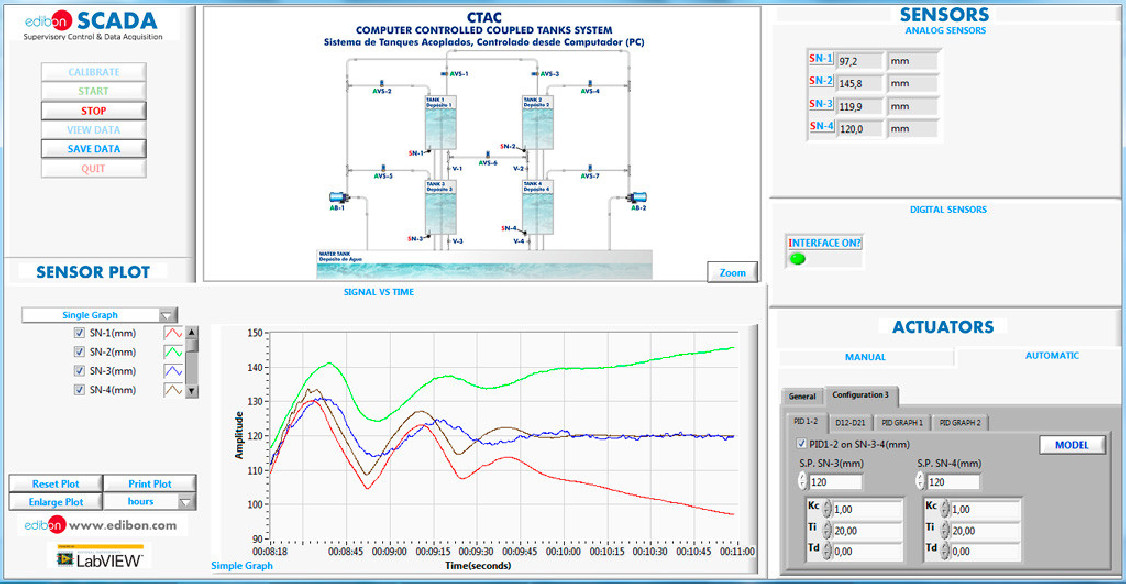

CTAC Computer Controlled Coupled Tanks System

INNOVATIVE SYSTEMS

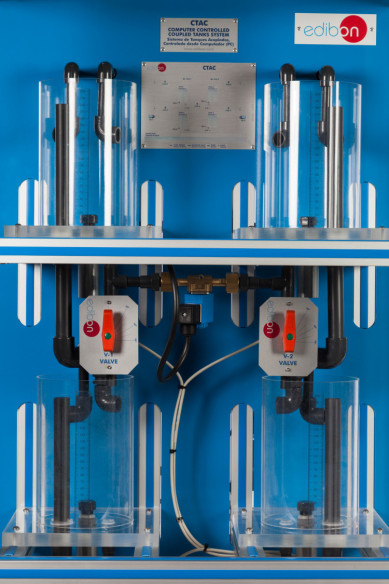

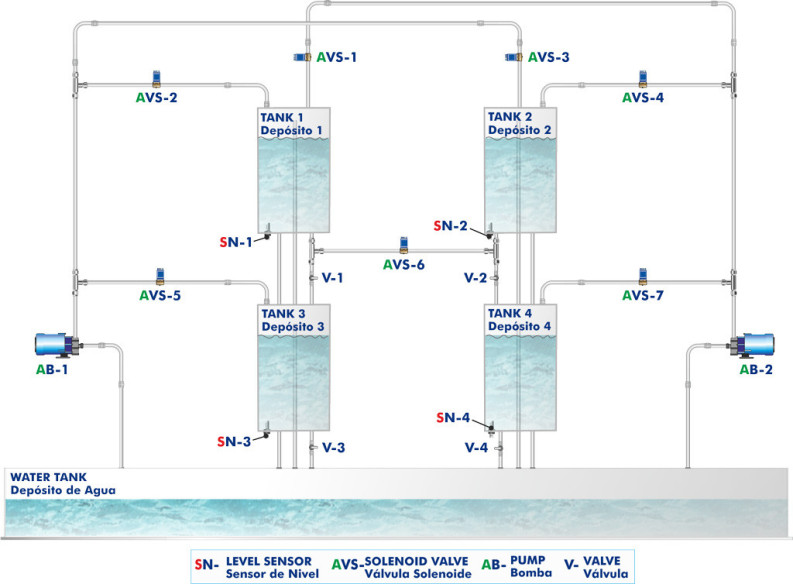

The Computer Controlled Coupled Tanks System, "CTAC", consists of four transparent tanks, each with a pressure sensor to measure the water level.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Coupled Tanks System, "CTAC", consists of four transparent tanks, each with a pressure sensor to measure the water level.

The coupling configuration between tanks can be modified by the use of computer controlled solenoid valves.

Two independently computer controlled pumps drive the water from the bottom to the tanks and, depending on how the valves are configured, from one tank to another.

Besides, the outlet of each tank includes a manual valve to introduce non measurable perturbations in the system.

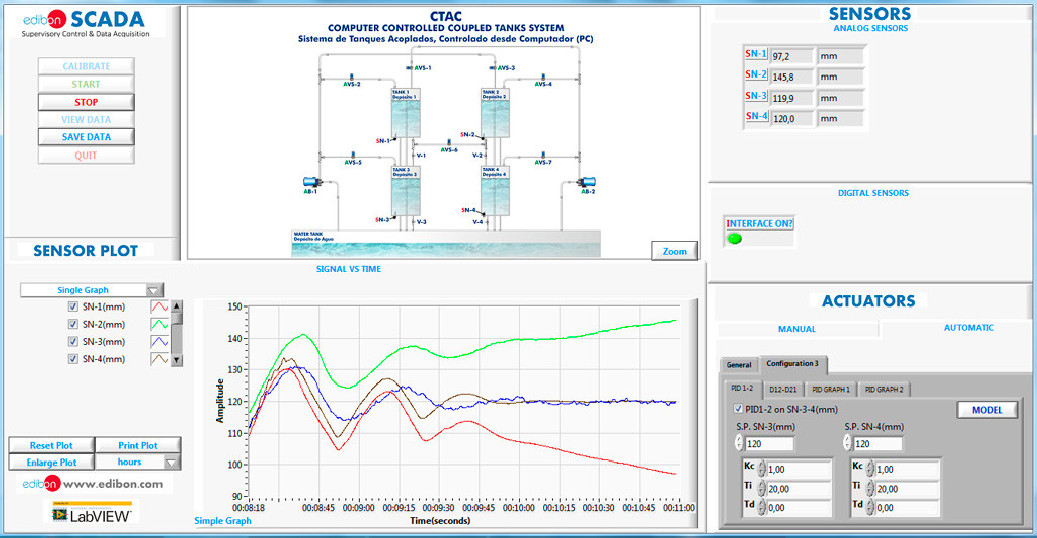

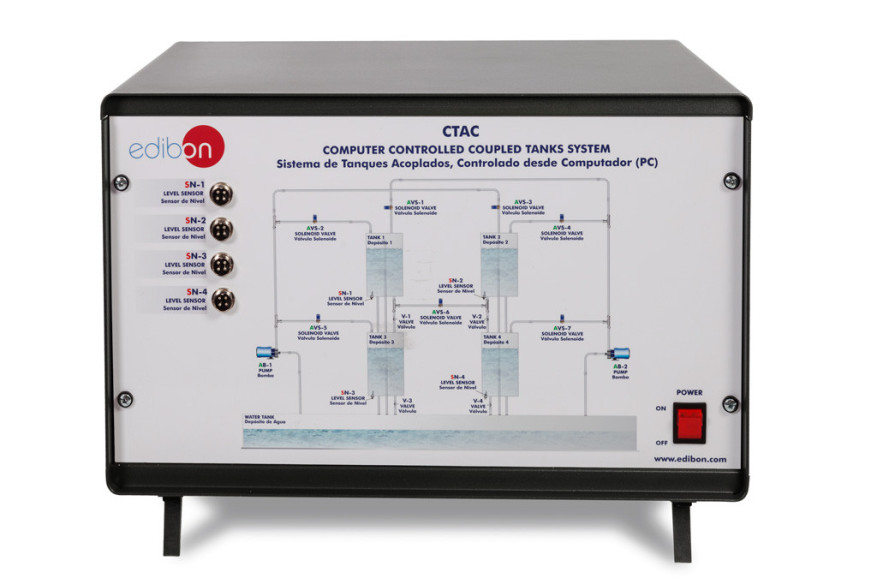

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study of nonlinear systems.

- Determination of the linear model of a tank: linearization.

- Determination of the linear model of a system with two coupled tanks.

- Study of the structure of a PID controller.

- PID control of the water level in a tank.

- Simultaneous control of the water level in a system formed by two tanks.

- Identification of systems.

- Study of different tanks coupling configurations.

- Study of the influence of some tanks on others in a four tanks system.

- Study of decouplers.

- Disturbance rejection.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the CTAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the CTAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Computer Controlled Process Control (Pneumatic Valve)

Computer Controlled Process Control (Speed Controller)

Computer Controlled Process Control Unit (Electronic + Pneumatic Valve and Speed Controller)

Computer Controlled Process Control Unit for the Study of Pressure (Air)

Computer Controlled Industrial Process Control Plant

Computer Controlled Industrial Process Control Plant (only Flow)

Computer Controlled Industrial Process Control Plant (only Temperature)

Computer Controlled Industrial Process Control Plant (only Level)

Computer Controlled Industrial Process Control Plant (only Pressure)

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences