TCPGC Computer Controlled Film and Dropwise Condensation Unit

INNOVATIVE SYSTEMS

The Computer Controlled Film and Dropwise Condensation Unit, "TCPGC", allows the visual and quantitative study of the condensation process in drops and film.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Film and Dropwise Condensation Unit, "TCPGC", has been specially designed for students use and to provide visual results and quantitative results related to heat transfer during condensation. Self-contained unit, which has its own steam generator and air extraction system, as well as condensers to provide dropwise and filmwise condensation.

The steam chamber is a thick-walled vertical glass cylinder, containing approximately 0.5 kg H2O, usually as saturated water and saturated steam.

Condensers:

- In film form: The condenser is made of natural copper with a built-in heat exchanger to preheat the cooling water. This serves to ensure that there is little variation in the temperature of the external copper face in which the vapour condenses. Three equally spaced thermocouples are fixed to the condenser. The cooling water inlet and outlet connections on the condenser are fitted with thermocouples for measuring the inlet and outlet water temperatures.

- In the form of drops: This is similar to the film-shaped condenser, except that the external surface of the condenser is gold plated to cause condensation in the form of drops.

The bottom plate carries an electric heating element that converts water into steam at a rate determined by the input of electrical current.

This steam circulates upwards towards the two condensers where it condenses by transferring the heat to the cooling water, and the condensed steam returns to the lower end of the chamber for re-evaporation. The water heating element is wound in a spiral and a control probe operates a thermostat which cuts off the action of the heating element in the event of overheating due to a shortage of water.

The chamber is equipped with three partitions to reduce the amount of splashes from the strong boiling.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Investigation of the saturation pressure/temperature relationship for H2O between about 20º C and 100 ºC.

- Visual demonstration of filmwise and dropwise condensation, and of nucleate boiling.

- Measurement of heat flow and surface heat transfer coefficient in both filmwise and dropwise condensation at pressures up to atmospheric.

- Demonstration and investigation of the effect of air in condensers.

- Demonstration of Dalton’s Law.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TCPGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TCPGC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

SUPPLEMENTARY EQUIPMENT

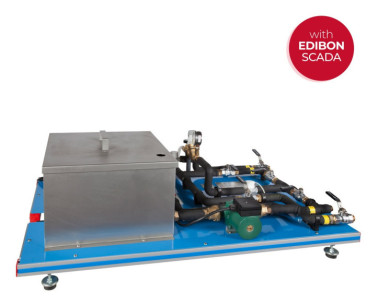

Computer Controlled Heat Exchangers Training System

Base Service Unit (Common for all available Heat Exchangers type "TI")

Concentric Tube Heat Exchanger for TICC

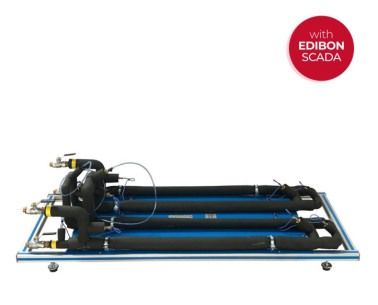

Extended Concentric Tube Heat Exchanger for TICC

Plate Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

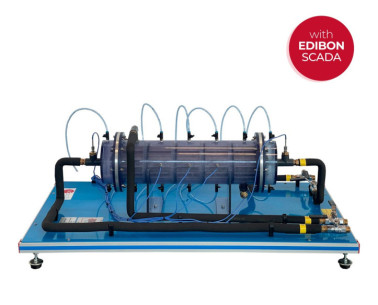

Shell & Tube Heat Exchanger for TICC

Jacketed Vessel Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Turbulent Flow Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

Heat exchanger Training System

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences