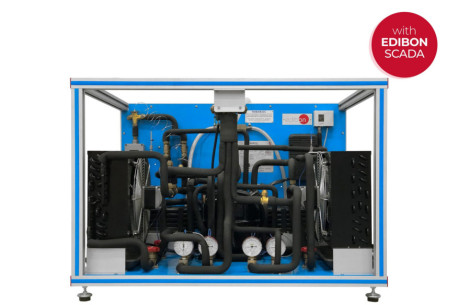

THAR22C Computer Controlled Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

INNOVATIVE SYSTEMS

The Computer Controlled Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)), "THAR22C", has as aim introduce the student to the study of the heat pumps, air conditioning and refrigeration, as well as the analysis and determinationof the operation typical parameters of the unit depending on the two types of fluids used in the processes of evaporation and condensation(air and water).

Expansions

Laboratories

RELATED NEWS

General Description

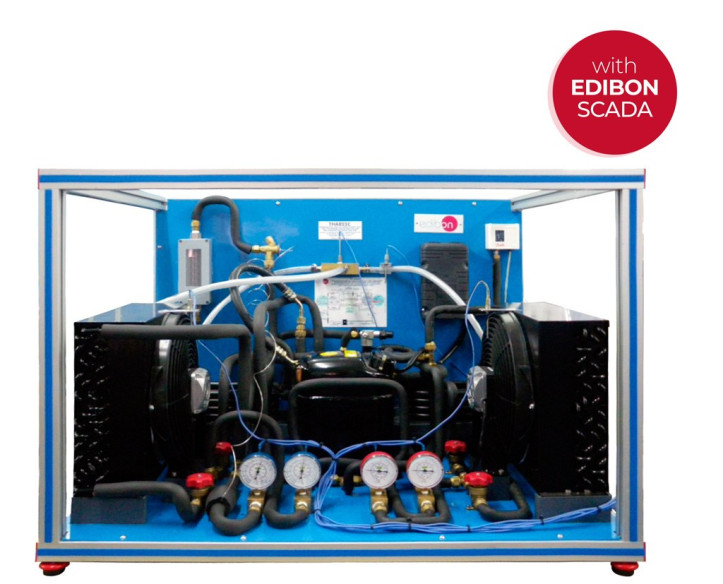

The Computer Controlled Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)), "THAR22C", has as aim introduce the student to the study of the heat pumps, air conditioning and refrigeration, as well as the analysis and determinationof the operation typical parameters of the unit depending on the two types of fluids used in the processes of evaporation and condensation(air and water).

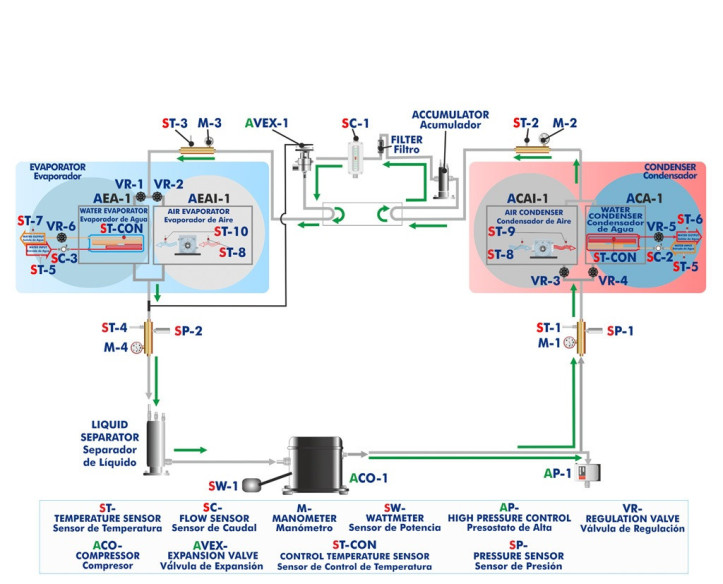

This unit can have different applications, depending on the type of cold focus or hot focus used in theprocesses of evaporation and condensation. This unit consists of the following stages:

- Compression:

This stage begins when the coolant enters to the compressor. This coolant is compressed,increasing its pressure and temperature. To measure these variables the unit includes a pressuresensor, a manometer and a temperature sensor.

- Condensation:

The coolant has two possibilities: divert the coolant through the air condenser, or through the water condenser. The coolant transfersits heat to the water (or to the air) that flows for the condenser. At the end of this stage, the pressure and the temperature of thecoolant are measured by means of a manometer and a temperature sensor.

- Expansion:

The coolant circulates through an accumulator and a filter, to retain particles of condensate, and a flow sensor. Next it circulatesthrough the valve of expansion, which causes a fall of pressure and temperature of the coolant. At the end of this stage, the pressureand the temperature of the coolant are measured by means of a manometer and temperature sensor.

- Evaporation:

The coolant has two possibilities: divert the coolant through the air evaporator, or through the water evaporator. The coolant absorbsthe heat of the water (or the air) that flows for the evaporator. At the end of this stage, the pressure and the temperature of the coolantare measured by means of a pressure sensor, a manometer and a temperature sensor. Finally, the coolant circulates through a liquidseparator to retain liquid particles before going on to the compressor.

The condensers and evaporators have different sensors to the measure of the most important parameters (temperatures and flows). Inaddition, the unit includes a high pressure control to avoid an excess of pressure in the unit.

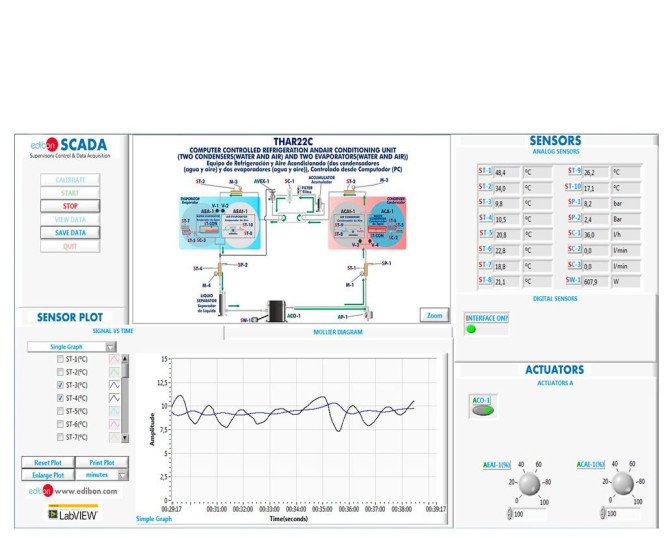

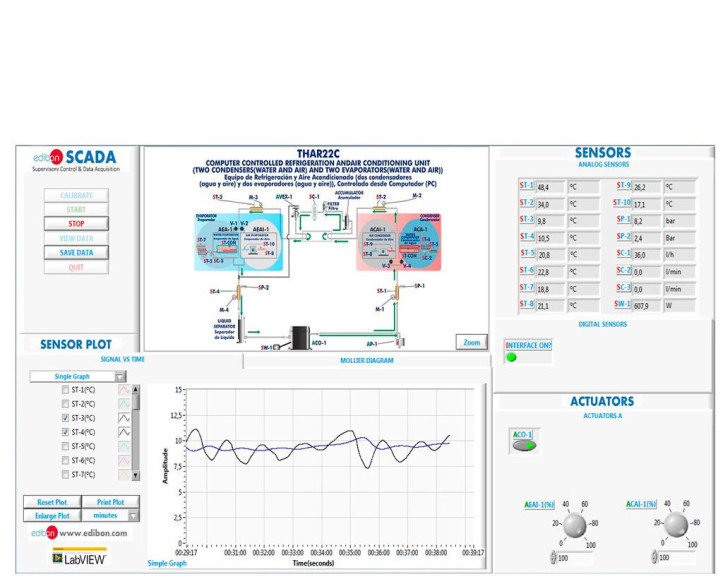

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Determination of the inlet power, heat produced and performance coefficient. Water as heat source. (Water-waterheat pump).

- Determination of the inlet power, produced heat and performance coefficient. Air as heat source. (Water-air heatpump).

- Determination of the inlet power, produced heat and performance coefficient. Air as heat source. (Air-air heat pump).

- Determination of the inlet power, heat produced and performance coefficient. Water as heat source. (Air-water heatpump).

- Preparation of performance curves of the unit at different inletand outlet temperatures. Water as heat source. (Water-waterheat pump).

- Preparation of performance curves of the unit at different inletand outlet temperatures. Air as heat source. (Water-air heatpump).

- Preparation of performance curves of the unit at different inletand outlet temperatures. Water as heat source. (Air-water heatpump).

- Preparation of the performance curves of the unit at differentinlet and outlet temperatures. Air as heat source. (Air-air heatpump).

- Lay out of the steam compression cycle in a diagram P-H and comparison with the ideal cycle. Water as heat source. (Waterwaterheat pump).

- Lay out of the steam compression cycle in a diagram P-H and comparison with the ideal cycle. Air as heat source. (Water-airheat pump).

- Lay out of the steam compression cycle in a diagram P-H and comparison with the ideal cycle. Water as heat source. (Airwaterheat pump).

- Lay out of the steam compression cycle in a diagram P-H and comparison with the ideal cycle. Air as heat source. (Air-air heatpump).

- Preparation of the performance curves of the unit based on the properties of the refrigerant and at different condensation and evaporation temperatures. Water as heat source. (Water-waterheat pump).

- Preparation of the performance curves of the unit based on the properties of the refrigerant and at different condensation and evaporation temperatures. Air as heat source. (Water-air heatpump).

- Preparation of the performance curves of the unit based on theproperties of the refrigerant and at different condensation andevaporation temperatures. Water as heat source. (Air-waterheat pump).

- Preparation of the performance curves of the unit based onthe properties of the refrigerant and at different condensation and evaporation temperatures. Air as heat source. (Air-air heatpump).

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Properties of the refrigerant R-513a.

- Enthalpy-Pressure diagram for the refrigerant R-513a.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the THAR22C unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the THAR22C unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Rerversible Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

Computer Controlled Rerversible Heat Pump + Air Conditioning + Refrigeration with 4 Condensers and 4 Evaporators (Water/Air)

Rerversible Heat Pump + Air Conditioning + Refrigeration with 4 Condensers and 4 Evaporators (Water/Air)

SUPPLEMENTARY EQUIPMENT

Computer Controlled Rerversible Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

Rerversible Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

Computer Controlled Rerversible Heat Pump + Air Conditioning + Refrigeration with 4 Condensers and 4 Evaporators (Water/Air)

Rerversible Heat Pump + Air Conditioning + Refrigeration with 4 Condensers and 4 Evaporators (Water/Air)

Heat Pump + Air Conditioning + Refrigeration with 2 Condensers and 2 Evaporators (Water/Air)

Heat Pump for different Heat Sources and Heat Exchangers

Underfloor Heating and/or Heat Source for Heat Pump

Fan Heater and/or Air Heat Exchanger

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences