TSTCC Computer Controlled Heat Transfer Series

INNOVATIVE SYSTEMS

The Computer Controlled Heat Transfer Series, "TSTCC," has been designed by EDIBON to study and compare different types of heat transfer on a small scale.

Laboratories

RELATED NEWS

General Description

The Computer Controlled Heat Transfer Series, "TSTCC," has been designed by EDIBON to study and compare different types of heat transfer on a small scale. It allows a wide range of heat transfer demonstrations and study the factors affecting and problems associated with different types of heat transfer.

The minimum supply consists of two main elements: Control Interface for TSTCC (Common for all "TXC" type units), "TSTCC/CIB", and at least one of the required elements described below.

Each heat transfer unit can be individually connected to the Control Interface for TSTCC (Common for all "TXC" type units) "TSTCC/CIB", which provides the necessary electrical supply and instrumentation connections for the study of the different types of heat transfer.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Accessories

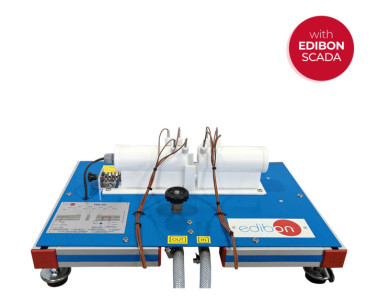

Linear Heat Conduction Unit for TSTCC

Radial Heat Conduction Unit for TSTCC

Radiation Heat Transfer Unit for TSTCC

Combined Free and Forced Convection and Radiation Unit for TSTCC

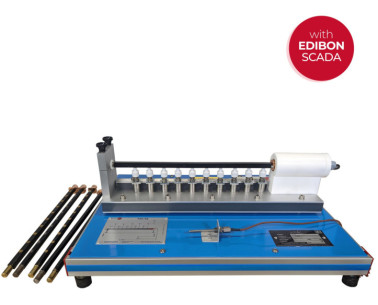

Extended Surface Heat Transfer Unit for TSTCC

Radiation Errors in Temperature Measurements Unit for TSTCC

Non-Steady State Heat Transfer Unit for TSTCC

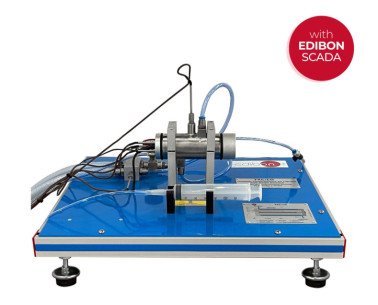

Thermal Conductivity of Liquid and Gas Unit for TSTCC

Free and Forced Convection Heat Transfer Unit for TSTCC

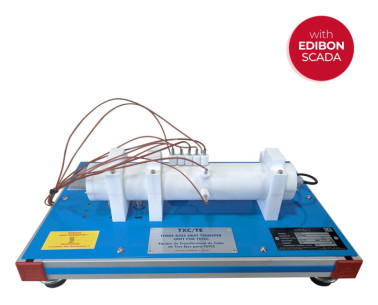

Three Axes Heat Transfer Unit for TSTCC

Metal to Metal Heat Transfer Unit for TSTCC

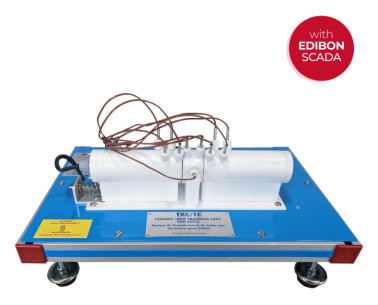

Ceramic Heat Transfer Unit for TSTCC

Insulating Material Heat Transfer Unit for TSTCC

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

Practices to be done with the Linear Heat Conduction Unit for TSTCC (TXC/CL):

- Conduction through a simple bar.

- Determination of the thermal conductivity "k".

- Conduction through a compound bar.

- Determination of the thermal conductivity, k, of the stainless steel.

- Determination of the thermal contact resistance Rtc.

- Effect of the cross sectional area.

- Insulating effect.

Additional practical possibilities:

- The thermal conductivity properties of insulators may be found by inserting paper or other elements between the heating and cooling sections.

- Understanding the use of the Fourier equation in determining rate of heat flow through solid materials.

- Sensors calibration.

Practices to be done with the Radial Heat Conduction Unit for TSTCC (TXC/CR):

- Radial conduction: Dependence on heating power.

- Radial conduction: Dependence on refrigeration flow.

Additional practical possibilities:

- Radial conduction.

- Determination of the thermal conductivity "k".

- Determination of the thermal contact resistance Rtc.

- Insulation effect.

- Understanding the use of the Fourier equation in determining rate of heat flow through solid materials.

- Sensors calibration.

Practices to be done with the Radiation Heat Transfer Unit for TSTCC (TXC/RC):

- Inverse of the distant square law for the radiation.

- Stefan Boltzmann Law.

- Emission power I.

- Emission power II.

- Kirchorff Law.

- Area factors.

- Inverse of the distant square law for the light.

- Lambert´s Cosine Law.

- Lambert Law of Absorption.

- Sensors calibration.

Practices to be done with the Combined Free and Forced Convection and Radiation Unit for TSTCC (TXC/CC):

- Demonstration of the combined heat transfer effect by radiation and convection on the surface of the cylinder. Determination of the combined heat transfer effect by forced convection and radiation.

- Demonstration of the influence of air flow in the heat transfer. Determination of the combined heat transfer effect by forced convection and radiation.

- Demonstration of the influence of input power in the heat transfer. Determination of the combined heat transfer effect by forced convection and radiation.

- Demonstration of the combined heat transfer effect of the radiation and convection on the surface of the cylinder. Determination of the combined heat transfer effect by free convection and radiation.

- Sensors calibration.

Additional practical possibilities:

- Determination of the airflow.

Practices to be done with the Radiation Errors in Temperature Measurement Unit for TSTCC (TXC/ER):

- Measurement the errors in thermocouples in function of its painting, material of its capsules, size.

- Radiation errors in temperature measurement and minimization of radiation errors due to shielding.

- Influence of the air flow on radiation errors in temperature measurement.

Additional practical possibilities:

- Heat transfer from geometry.

- Effect of cross-sectional shape on heat transfer from a geometry.

- Heat transfer from geometries of two different materials.

- Radiation errors in temperature measurements.

- Effect of air velocity on measurement errors.

- Calibration of sensors.

Practices to be done with the Extended Surface Heat Transfer Unit for TSTCC (TXC/SE):

- Heat transfer from a Fin.

- Effect of cross section shape in heat transfer from a Fin.

- Heat transfer from Fins of two different materials.

Additional practical possibilities:

- Measuring the temperature distribution along an extended surface.

- Sensors calibration.

Practices to be done with the Unsteady State Heat Transfer Unit for TSTCC (TXC/EI):

- Predicting temperature at the center of a cylinder using transient conduction with convection.

- Predicting the conductivity of a similar shape constructed from a different material.

- Conductivity and temperature dependence on volume.

- Conductivity and temperature dependence on surrounding temperature T∞.

- Sensors calibration.

Practices to be done with the Thermal Conductivity of Liquids and Gases Unit for TSTCC (TXC/LG):

- Determining the heat losses of the system.

- Obtaining the thermal conductivity of gases and liquids.

- Thermal conductivity under vacuum conditions.

- Determining the temperature distribution in cylindrical bodies.

Additional practical possibilities:

- Obtaining of the curve of thermal conductivity of the air.

- Water thermal conductivity determination.

- Thermal conductivity determination of a mineral oil.

- Calibration of the unit.

- Sensors calibration.

- Dry air thermal conductivity under atmospheric pressure.

Exercises and Practical Possibilities to be done with the Main Items Practices to be done with the Free and Forced Convection Heat Transfer Unit for TSTCC (TXC/FF):

- Free convection in flat surfaces.

- Forced convection in flat surfaces.

- Efficiency calculation of the forced convection process in flat plate.

- Forced convection in a pinned exchanger: efficiency.

- Forced convection in a finned exchanger: efficiency.

- Temperature distribution in the additional surfaces.

Additional practical possibilities:

- Demonstration of the basic principles of free and forced convection.

- Comparison between free and forced convection.

- Dependence of the heat transfer with the temperature.

- Dependence of the heat transfer with the speed of the fluid.

- Dependence of the heat transfer with the exchanger geometry (finned or pinned surface).

- Study of the advantage of using pinned and finned surfaces in heat transfer in free convection.

- Study of the advantage of using pinned and finned surfaces in heat transfer in forced convection.

- Comparative study between the free convection of a horizontal surface and vertical surface.

- Sensors calibration.

Practices to be done with the Three Axes Heat Transfer Unit for TSTCC (TXC/TE):

- Conduction in a simple bar.

- Determination of the thermal conductivity of "K".

Additional practical possibilities:

- Conduction through three axes.

- Sensors calibration.

Practices to be done with the Metal to Metal Heat Transfer Unit for TSTCC (TXC/MM):

- Conduction in a simple bar.

- Determination of the thermal conductivity of "k".

- Determination of the thermal contact resistance Rtc.

- Sensors calibration.

Practices to be done with the Ceramic Heat Transfer Unit for TSTCC (TXC/TC):

- Conduction in a simple bar.

- Determination of the thermal conductivity "k".

- Conduction through a compound bar.

- Determination of the thermal contact resistance Rtc.

- Sensors calibration.

Practices to be done with the Insulating Material Heat Transfer Unit for TSTCC (TXC/TI):

- Determination of the thermal conductivity "k".

- Calculation of the heat transfer properties of different specimens.

- Conduction through a compound bar.

- Insulation effect.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Control Interface for TSTCC (Common for all available modules type "TXC")

Linear Heat Conduction Unit for TSTCC

Radial Heat Conduction Unit for TSTCC

Radiation Heat Transfer Unit for TSTCC

Combined Free and Forced Convection and Radiation Unit for TSTCC

Extended Surface Heat Transfer Unit for TSTCC

Radiation Errors in Temperature Measurements Unit for TSTCC

Non-Steady State Heat Transfer Unit for TSTCC

Thermal Conductivity of Liquid and Gas Unit for TSTCC

Free and Forced Convection Heat Transfer Unit for TSTCC

Three Axes Heat Transfer Unit for TSTCC

Metal to Metal Heat Transfer Unit for TSTCC

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences