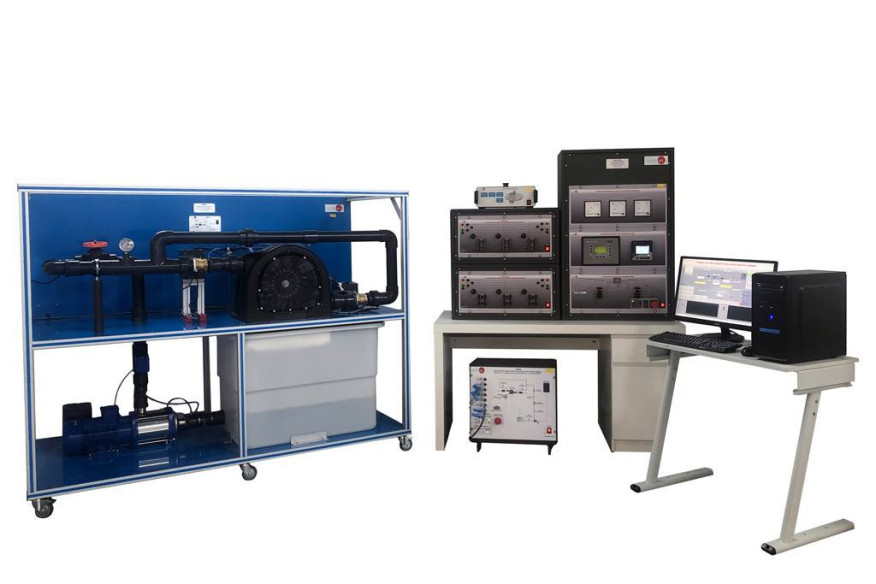

The Computer Controlled Hydroelectric Power Plant with Pelton Turbine, "HPPP," has been designed by EDIBON to investigate and study the operation of hydroelectric power plants based on Pelton turbines. It also allows for the analysis of the mechanical characteristics of this type of turbine.

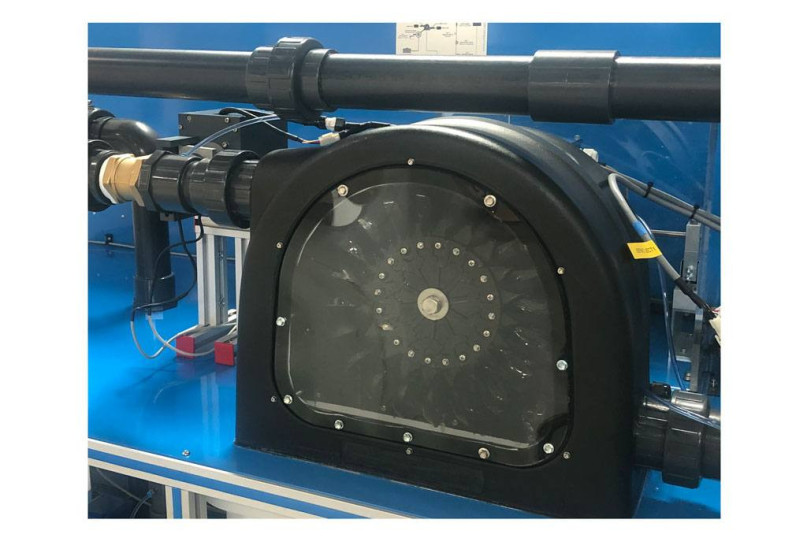

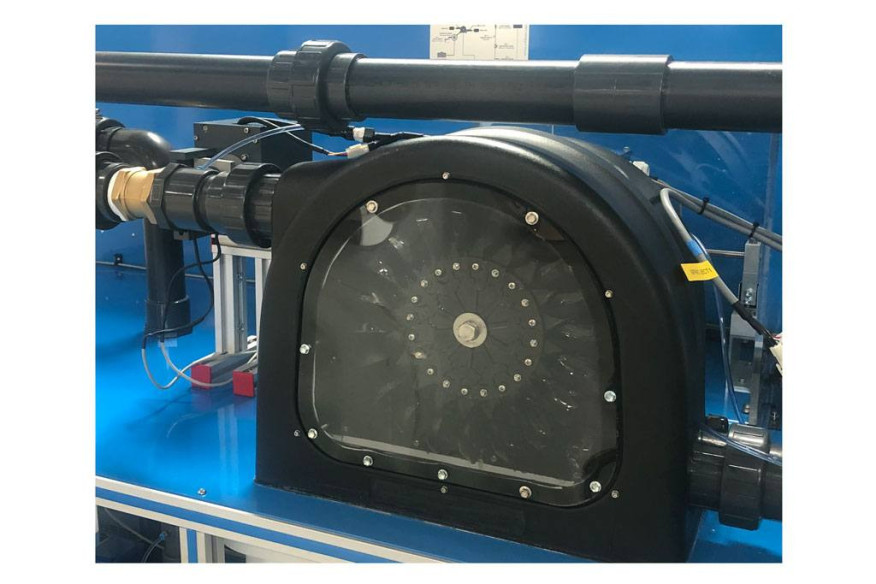

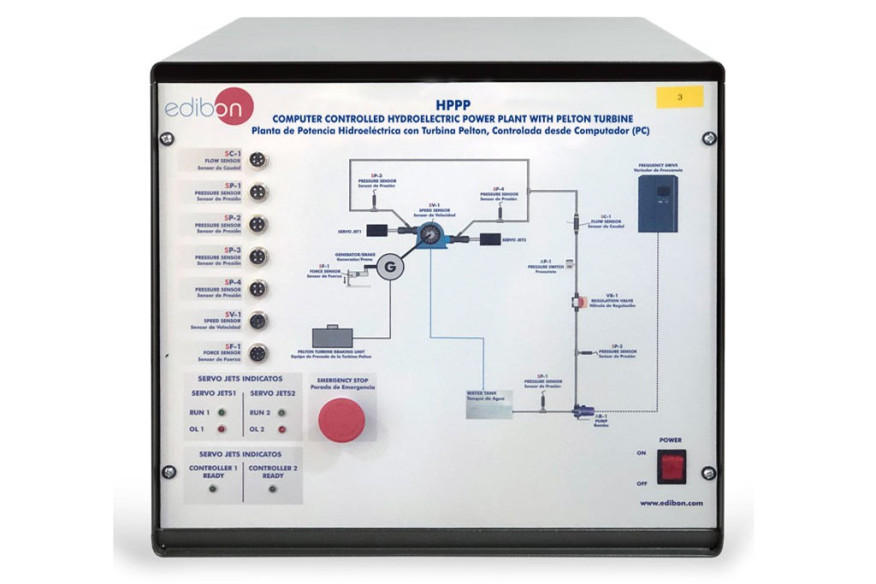

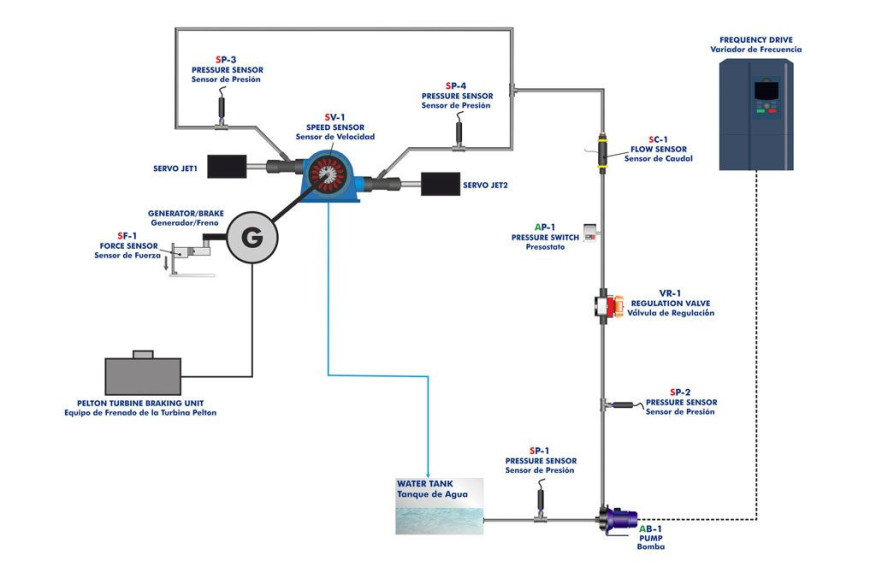

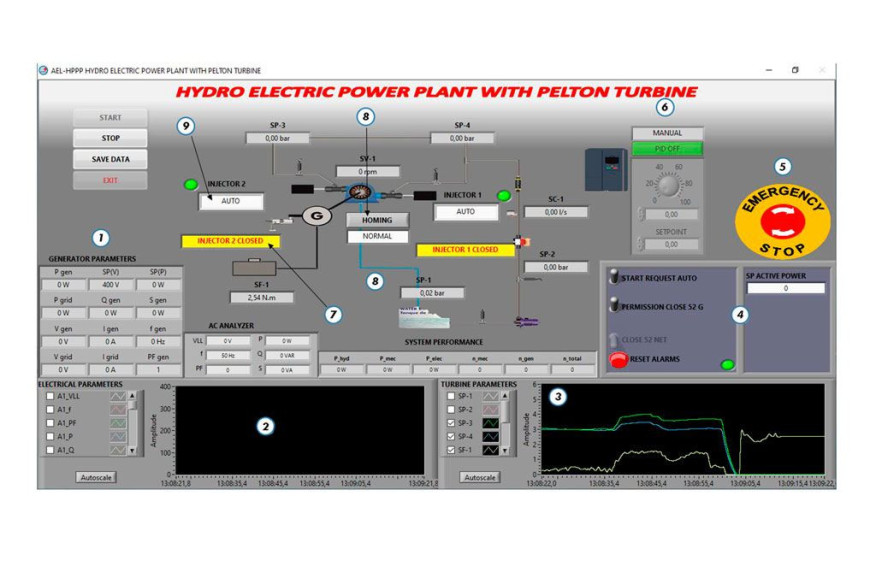

From the mechanical point of view, this unit is built with an aluminum and steel structure that integrates the following components: a 1 kW Pelton turbine with two servo-driven injectors, a water tank to simulate the reservoir, a water pump that allows simulating a waterfall of up to 80 meters, 2-inch PVC pipes for channeling the water from the pump to the injectors, and two servomotors that control the opening and closing of the injectors. These injectors can be controlled manually from the SCADA system or automatically by means of an advanced controller, which is described later in this catalog. In addition, the "HPPP" part number incorporates strategically placed sensors to measure and analyze physical variables of the system, such as flow, pressure such as flow, pressure, speed and torque. These sensors allow the user to visualize and analyze the partial and total efficiencies of the turbine and plant, the torque exerted by the turbine as a function of the injector opening, the mechanical power developed, the water flow required the water flow required to generate this power, the optimization of the turbine performance according to the ideal water head, and the impact of the turbine’s and the impact of the asymmetry of the pressures of the two injectors on the turbine performance, among other aspects.

From the electrical point of view, it is recommended to purchase the resistive and capacitive loads "N-REVT/1K" and "N-CAR19T/3C", as well as the Control and Regulation Unit for HPPP, "HPPP-CR", which includes all the electrical elements necessary to control the Pelton turbine as a power plant. First of all, it has analog measuring instruments, such as a voltmeter, a wattmeter and a varimeter, which provide information on the electrical parameters of the generator. In addition, there is the advanced controller, whose function is to automatically govern the position of the servo injectors in relation to the electrical power generated. This multifunction controller acts as protection against over-frequency, over-voltage, over-current and reverse power, providing safety and realism to the system. Next to the advanced controller is a network analyzer, which allows to measure and visualize all the electrical parameters that the generator injects into the real electrical network when it is synchronized. In addition, the unit can operate in island mode, supplying power to a number of electrical loads already mentioned in this paragraph.

All electrical and mechanical parameters are collected by the Supervisory Control and Data Acquisition (SCADA) system included in the unit. SCADA is an essential tool for analyzing every detail of the operation of a turbine or hydroelectric power plant. All parameters can be graphically visualized, enabling a step-by-step understanding of the dynamics of such systems. For example, the influence of pressure head on turbine mechanical power, variation in performance based on injector opening, and its impact on turbine torque, among others.

Cookie preferences

Cookie preferences