AMTC Computer Controlled Pipe Network Unit, with Hydraulics Bench (FME00)

INNOVATIVE SYSTEMS

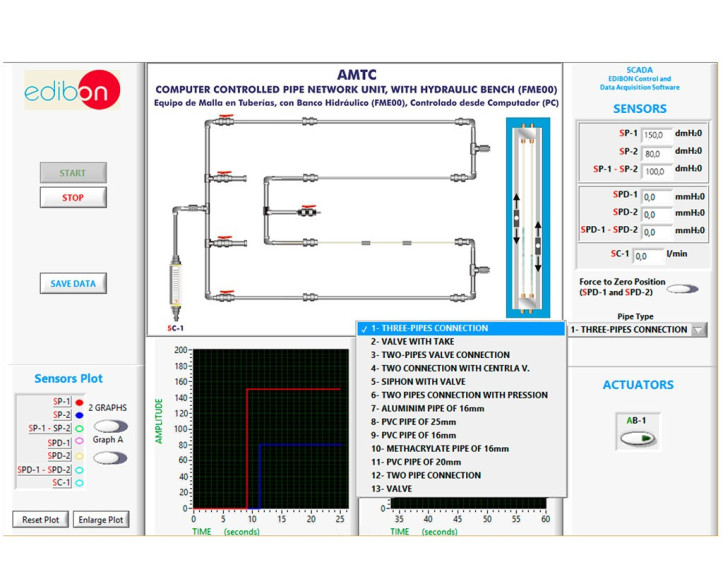

The Computer Controlled Pipe Network Unit, with Hydraulics Bench (FME00), "AMTC", has been designed by EDIBON to enable different pipe network installations, measuring flow and pressure, and always using water as test fluid.

Expansions

Laboratories

RELATED NEWS

General Description

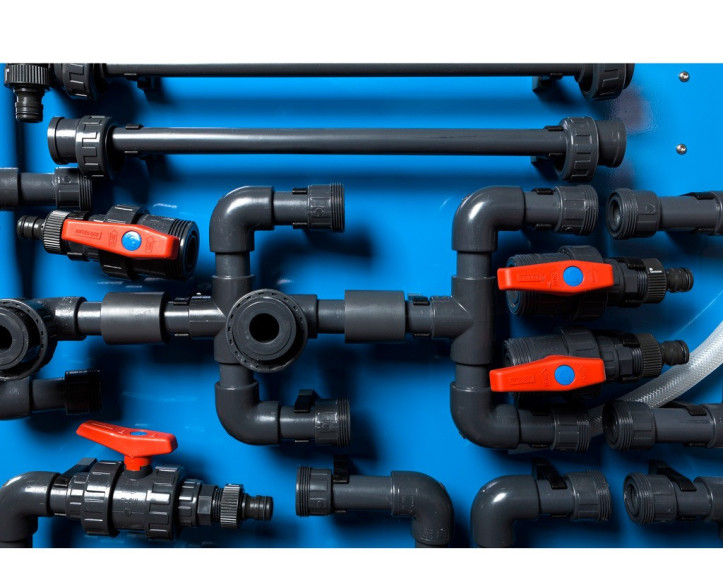

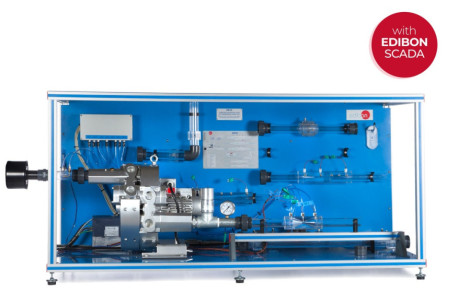

The Computer Controlled Pipe Network Unit, with Hydraulics Bench (FME00), "AMTC", consists of a pipe network, a lateral panel where all the elements to test are located and a hydraulics bench, which has all the elements and accessories required for the unit to work autonomously.

The valves that some of the elements have in order to form the different circuits are On-Off valves, necessary to distribute the flow along the net.

The unit has a system of anti-blockage pressure takings, located upstream and downstream of each element that is going to be tested. All of them have a quick and easy connection to the pressure measurement devices of the unit.

The unit includes an Hydraulics Bench (FME00), that has a volumetric measuring system, consisting of a two-level tank. The small one is used to measure low flows and the big one, to measure higher flows. A gauge, which consists of a scale and a transparent tube is connected to a bypass on the base of tank and gives an instantaneous measurement of the water level.

A centrifugal pump located inside the hydraulics bench is used to add energy to the fluid. The flow can be regulated by a control valve located on the hydraulics bench.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Head losses in a PVC pipe.

- Head losses in an aluminum pipe.

- Head losses in a methacrylate pipe.

- Study of head losses in pipes of the same material.

- Study of head losses in function of the material.

- Friction coefficient in a PVC pipe.

- Friction coefficient in an aluminum pipe.

- Friction coefficient in a methacrylate pipe.

- Study of the friction coefficient in function of the material.

- Study of the friction coefficient in function of the diameter.

- Parallel network configuration for pipes of same material and different diameter.

- Parallel network configuration for pipes of different material and same diameter.

- Series network configuration for pipes of same material and different diameter.

- Series network configuration for pipes of different material and same diameter.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the AMTC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the AMTC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Pipe Network Unit, with Hydraulics Bench (FME00/B)

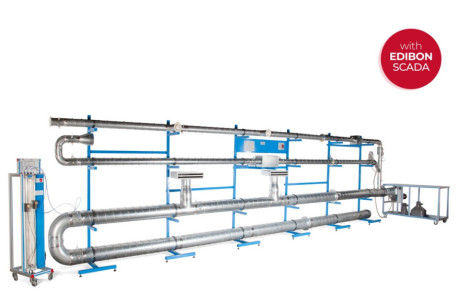

Mesh in Pipe Unit

SUPPLEMENTARY EQUIPMENT

Computer Controlled Fluid Friction in Pipes, with Hydraulics Bench (FME00)

Fluid Friction in Pipes Unit, with Hydraulics Bench (FME00)

Fluid Friction in Pipes Unit, with Basic Hydraulics Feed System (FME00/B)

Fluid Friction in Pipes Unit

Pipe Network Unit, with Hydraulics Bench (FME00)

Pipe Network Unit, with Hydraulics Bench (FME00/B)

Mesh in Pipe Unit

Unit to Study the Pressure Drop of Compressible Fluids in Pipes

Computer Controlled Water Hammer Unit

Computer Controlled Flow of Compressible Fluids Unit

Computer Controlled Unit for Transient Drainage Processes in Storage Reservoirs

Computer Controlled Air Duct Systems Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences