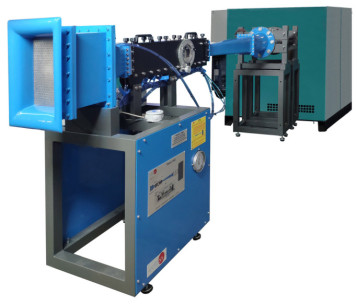

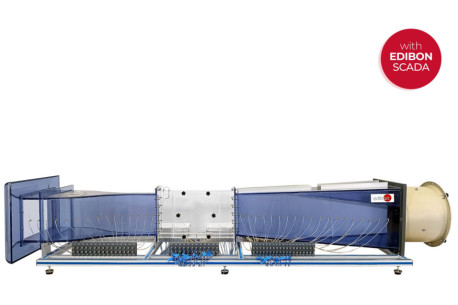

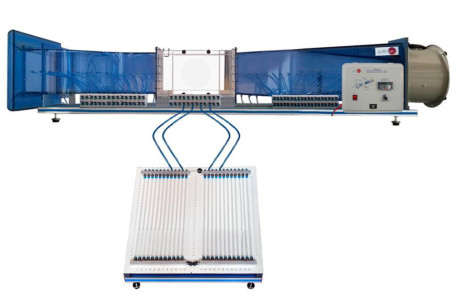

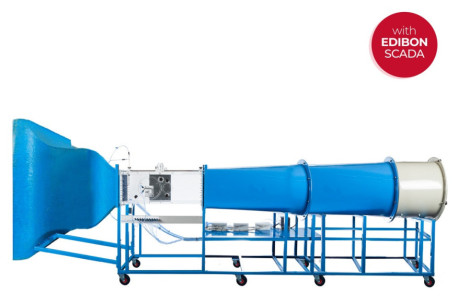

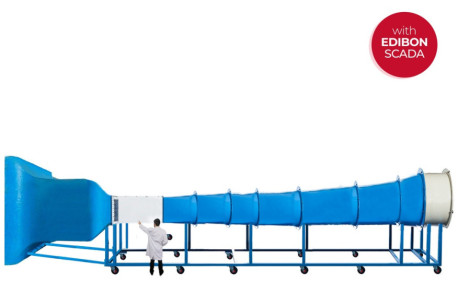

The Computer Controlled Supersonic Wind Tunnel (Three Blowers), "TAS25/100C-3B", is an open wind tunnel for the study of theaerodynamic properties of different drag bodies subject to subsonic and supersonic flows.

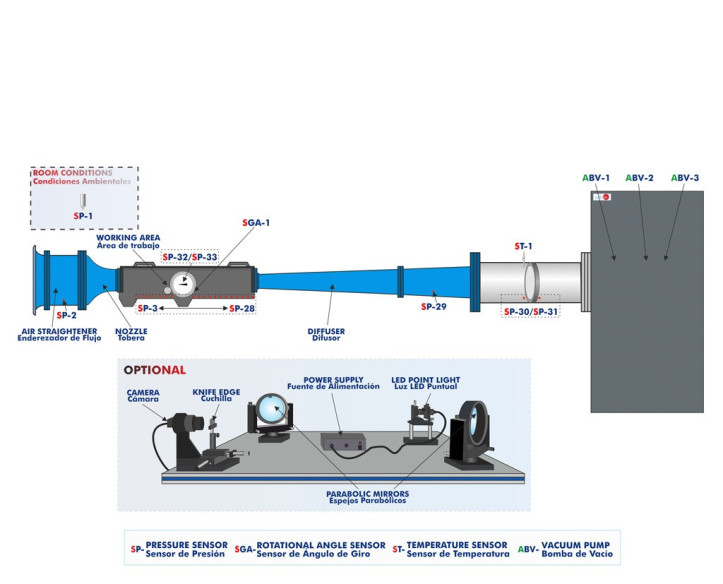

Airflows through three vacuum pumps or blowers incorporating a computer controlled powerregulator, located on the discharge side of the tunnel. The air enters the tunnel through anozzle, which has a flow rectifier where the fluid is accelerated. Then, the transparent workingsection is located, which consists of a section where the resistance models are mounted, and theaccelerated air flows around these models. The models included have different forms: rocket,projectile, wedges of different slops and double wedge with different inclinations.

There are three different upper profiles of the working section to generate different velocities upto two times the speed of sound (2 Mach).

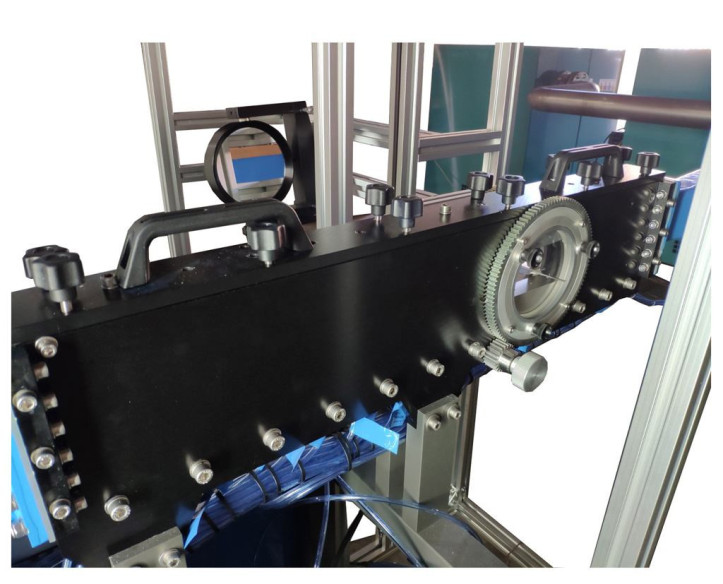

The optional "TAS25/100-SO" accessory, an optical Schlieren system, allows you to directlyobserve and photograph the supersonic flow and shock fronts formed around the aerodynamicmodels, thus enabling a greater number of experiments.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

Cookie preferences

Cookie preferences