The Computer Controlled Thin Film Evaporator, "EPFC", has been designed by EDIBON to study (theoretical and practically) the different operating variables that influence the thin film evaporation process.

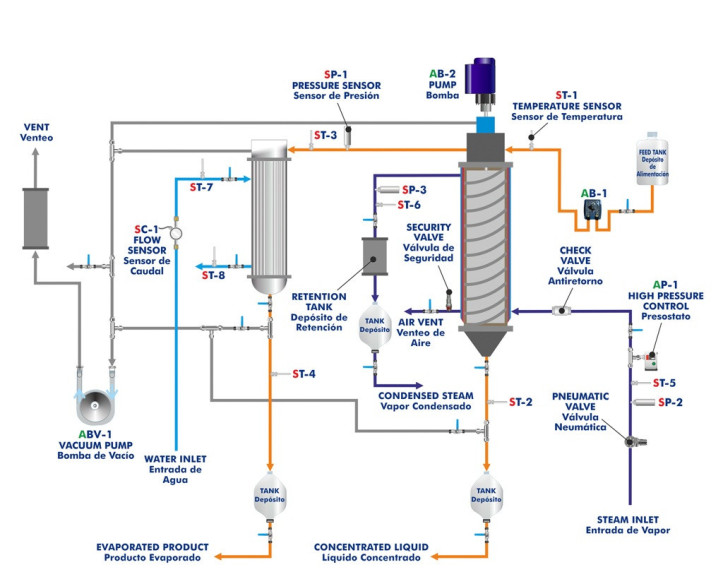

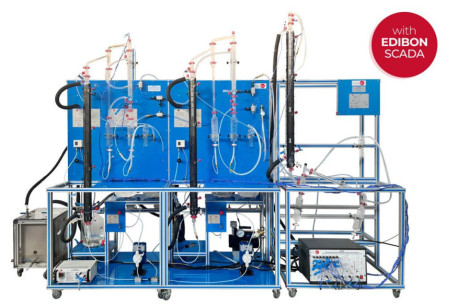

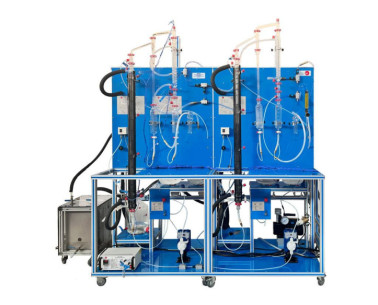

The unit is formed by a thin film evaporator, a shell-and-tube condenser, a liquid-ring vacuum pump, several tanks and the elements required to carry out the study of the different variables of the thin film evaporation process.

The solution to be concentrated is transferred from a storage tank to the evaporator by a peristaltic pump (computer controlled).

The thin film evaporator consists of a cylindrical tube with a steam heating jacket and an inner rotor with a motor (computer controlled). The liquid to be evaporated enters the evaporator above the heated zone and is distributed evenly over the inner circumference of the evaporator wall by the rotor, this produces a very thin liquid film on the cylinder wall. The vaporized solvent ascends through the evaporator and the concentrated liquid descends through the evaporator.

The steam is injected to the heating jacket from a steam generator (not included). This line includes a steam trap, a security valve, a check valve, a high pressure switch and a computer controlled solenoid valve.

The evaporator operates under vacuum conditions using the liquid-ring vacuum pump (computer controlled) to obtain vacuum levels in the evaporator.

The concentrated liquid is stored into a borosilicate glass tank. The vaporized solvent is condensed in the shell-and-tube condenser, through which cooling water flows, and then stored into a borosilicate glass tank.

Pressure, temperature and flow sensors are supplied where necessary, as well as adequate sampling and drain valves.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookie preferences

Cookie preferences