FOR FURTHER INFORMATION, CONTACT US

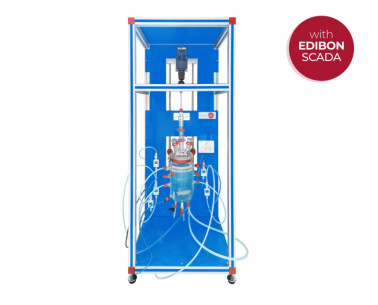

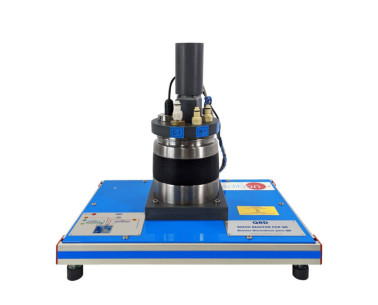

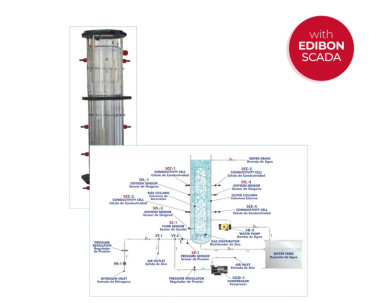

11.2.- CHEMICAL REACTORS

A chemical reactor is a device in which a chemical reaction can be produced. This means that a change in the chemical composition of the introduced matter takes place inside the reactor.

View moreThey are designed in such a way that the best conversion and selectivity are obtained, the most optimal results possible. They can contain a catalyst, a compound that improves the reaction kinetics, depending on the reaction carried out. If this catalyst is a purified enzyme or the organism that contains that enzyme, then we are talking about bioreactors.

There are several reactors classifications: depending on the number of phases (homogeneous and heterogeneous), the thermal regime (isothermal or adiabatic) and the type of operation (discontinuous, continuous or flow and semicontinuous). Depending on the type of operation:

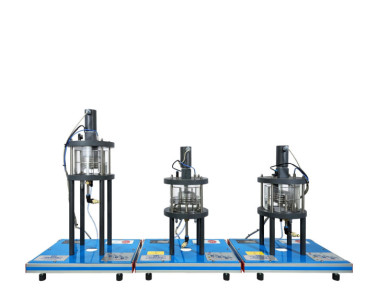

- Continuous. Perfect mix/stirred tank reactor (CSTR), plug flow/tubular reactor.

- Discontinuous. Stirred tank reactor (batch).

According to the number of phases:

- Homogeneous. A single phase. Fixed bed, moving bed, fluidized bed, etc.

- Heterogeneous. Several phases. They can be catalytic or non-catalytic. The fixed bed and fluidized bed are the most common examples of catalytic heterogeneous reactor.

These are the most common reactors, although there are many others such as combined reactors in series, enzymatic catalytic reactors, recycle reactors, etc.

Given the technological progress, it has been possible to study kinetics of chemical reactions and the design of reactors using process simulation systems. Besides, there is an advance in terms of process control to solve certain problems in the chemical industry and also comply with environmental restrictions.

Linked to the care of the environment, the chemical industry has been adapting and investigating about ideal new materials, catalysts, etc., which comply with environmental constraints.

View Products Cookie preferences

Cookie preferences