TIVE Jacketed Vessel Heat Exchanger for TICC

INNOVATIVE SYSTEMS

The Jacketed Vessel Heat Exchanger for TICC, "TIVE", designed by EDIBON, provides a comprehensive environment for the detailed study of heat transfer between two non-mixing fluids. In this unit, hot water flows through a jacket, transferring heat to the cold water flowing inside the vessel. This way, the hot fluid heats the jacket, allowing the heat to be transferred to the cold fluid inside the vessel.

Expansions

Laboratories

RELATED NEWS

General Description

The Jacketed Vessel Heat Exchanger for TICC, "TIVE", designed by EDIBON, provides a comprehensive environment for the detailed study of heat transfer between two non-mixing fluids. In this unit, hot water flows through a jacket, transferring heat to the cold water flowing inside the vessel. This way, the hot fluid heats the jacket, allowing the heat to be transferred to the cold fluid inside the vessel.

This heat exchanger is commonly used in industrial applications to heat or cool liquids in tanks or containers, such as in the food, chemical, or pharmaceutical industries, among others.

This unit enables the analysis of heat transfer variation under different conditions, such as changes in flow rate, temperature, and flow type. With a design optimized for efficient heat transfer, the Jacketed Vessel Heat Exchanger for TICC provides an effective tool for analysis and experimentation in heat exchange. Additionally, it allows temperature measurement between the jacket and the vessel, which is essential for ensuring efficient thermal exchange and detecting potential issues, facilitating the monitoring of the exchanger’s efficiency and design optimization. These detailed measurements enable adjustments to the exchanger’s operation to improve its performance and ensure adequate heat flow between the circulating fluids.

In summary, the Jacketed Vessel Heat Exchanger for TICC, "TIVE", offers students, professors, and researchers the opportunity to deeply understand and apply the fundamental principles of heat transfer in jacketed vessel exchangers. Thanks to its innovative design, this unit provides a detailed and applicable understanding in the industry.

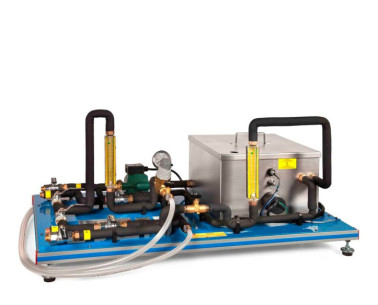

To work with this unit, the Base and Service Unit, "TIUS", is required, which provides key functions such as heating water using a thermostatic bath, pumping hot water, regulating and measuring the flow rates of cold and hot water, measuring the inlet and outlet temperatures of cold and hot water, as well as measuring the pressure drop in the heat exchanger.

These Computer Controlled Units are supplied with EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Global balance of energy in the heat exchanger and losses study.

- Determination of the exchanger effectiveness. NTU Method.

- Influence of the flow on the heat transfer. Calculation of the number of Reynolds.

- Influence of the vessel stirring on the heat transfer when operating in batches.

- Influence of the vessel’s water volume on the heat transfer when operating in batches.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Study of the hysteresis of the flow sensor.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TICC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TICC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

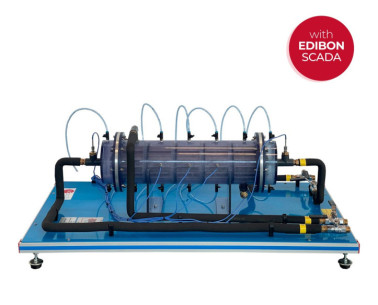

Plate Heat Exchanger for TICC

Shell & Tube Heat Exchanger for TICC

Concentric Tube Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Extended Concentric Tube Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

SUPPLEMENTARY EQUIPMENT

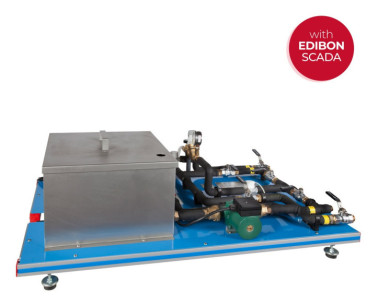

Computer Controlled Heat Exchangers Training System

Base Service Unit (Common for all available Heat Exchangers type "TI")

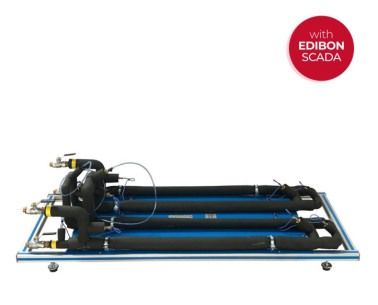

Concentric Tube Heat Exchanger for TICC

Extended Concentric Tube Heat Exchanger for TICC

Plate Heat Exchanger for TICC

Extended Plate Heat Exchanger for TICC

Shell & Tube Heat Exchanger for TICC

Coil Vessel Heat Exchanger for TICC

Turbulent Flow Heat Exchanger for TICC

Cross Flow Heat Exchanger for TICC

Heat exchanger Training System

Base Service Unit (Common for all available Heat Exchangers type "TI..B")

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences