At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

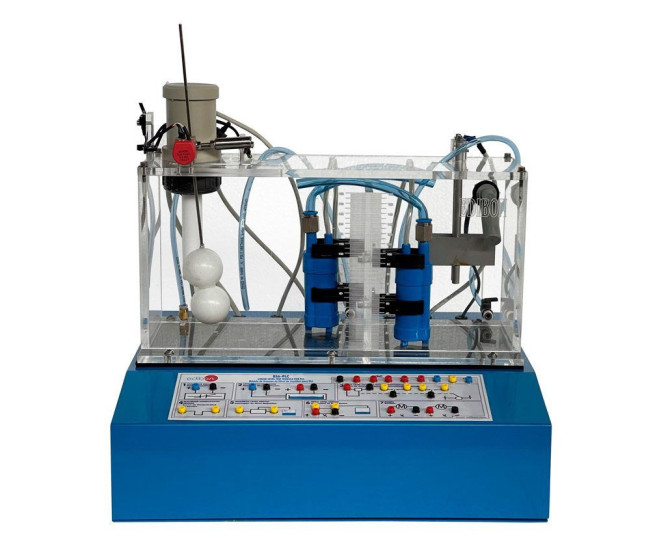

BS6-PLC Liquid Level Test Module for PLC

INNOVATIVE SYSTEMS

The "BS6-PLC" has been designed to study the liquid level measurement and control techniques of a tank through a PLC.

RELATED NEWS

General Description

The "BS6-PLC" has been designed to study the liquid level measurement and control techniques of a tank through a PLC. This unit is unit with two tanks with sensor of different technology for level measurement. One of the level sensor output signals is conditioned to be connected to the PLC. Each tank has an individual DC pump, which can be used to pump liquid from one tank to another. The level control of liquid can be controlled by PLC depending on the obtained signals from a sensor.

* Available PLC models of different manufacturers: PANASONIC, SIEMENS, OMRON, MITSUBISHI, ALLEN BRADLEY, etc.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- To use a capacitive sensor to measure the liquid level in the tank.

- To use the differential pressure sensor as an element to determine the water level in a tank.

- To use a changeable resistance fixed to a float system as a liquid level measurement element.

- Conduction Sensor. Use of a sensor made up of to steel electrodes to measure the water level of a tank.

- Magnetic float level sensor. It detects a precise liquid level in the tank with a magnetic contact.

- Control of the module left tank liquid level using an optical level sensor.

- Using the analog inputs and outputs of the PLC to read and write analog signals.

- Read the tachometer signal with the PLC.

- Manual control of the actuator through the PLC.

- PID control of the angular speed value through the PLC.

- Observe the effects of the angular speed control to changes in the PID parameters.

SUPPLEMENTARY EQUIPMENT

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS-PLC

The Modular System for the Study of Sensors with PLC Control, "PLC-BS", are a large number of modules that show the operation of different sensors to understand the sensor control applications of different technologies, applied to common...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS2-PLC

Temperature Test Module for PLC

The "BS2-PLC" has been designed to study the use and applications of temperature sensors as a measure device and how to perform a temperature control through a PLC. TThe unit has a half-open space inside which there is a lamp that heats the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS3-PLC

Pressure Test Module for PLC

The "BS3-PLC" has been designed to study the pressure measurement techniques and control application with a PLC. This unit is equipped with a pressure chamber with several sensors, with different uses and applications, adjusted to measure the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS4-PLC

Flow Test Module for PLC

The "BS4-PLC" has been designed to study the flow measurement techniques and control with PLC. This unit is unit with two tanks assembled on a structure with a pumping system that allows pumping the water from the reservoir tank, through the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS5-PLC

Ovens Test Module for PLC

The "BS5-PLC" has been designed to study the temperature measurement techniques inside a sealed place, such as an oven and how to perform a temperature control through a PLC. This unit is equipped with an oven that contains a heating element and a...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS7-PLC

Tachometers Test Module for PLC

The "BS7-PLC" has been designed to study the linear and angular speed measurement techniques through a PLC. This unit is unit with a miniature motor to move an axle at different speeds, being able to adjust de motor speed by changing the voltage...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS9-PLC

Pneumatic Test Module for PLC

The "BS9-PLC" has been designed to study the control and handling techniques of a pneumatic actuator through a PLC. The actuator is a double acting pneumatic cylinder that allows moving a platform. The displacement of the piston axle is detected...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS10-PLC

Light Test Module for PLC

The "BS10-PLC" has been designed to study different light measurement techniques and control light intensity through a PLC. This unit is composed of a lamp whose intensity can be controlled according to the voltage applied and a series of...

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences