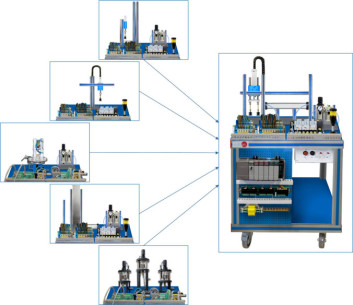

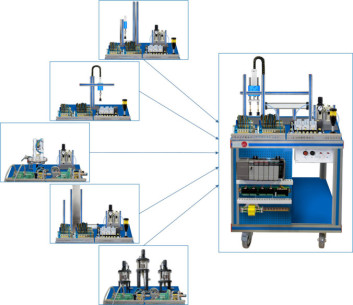

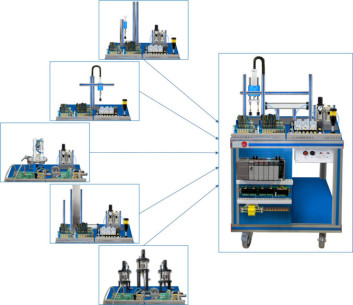

The Pieces Feeder Workstation, "AE-PLC-APS", is a unit that works with pneumatics and electro-pneumatics technologies.

The function of the "AE-PLC-APS" is to supply pieces and to verify them, if they are acceptable.

The pieces will be supplied one by one by a pneumatic cylinder, and then the position of the piece will be verified in order to activate the mechanism that checks whether the piece is acceptable.

Afterwards, the piece is displaced to the outlet area if it is correct or discarded if it is wrong.

The "AE-PLC-APS", designed by EDIBON, allows the user to learn about the basic concepts of pneumatics and electro-pneumatics (operation, elements of each circuit, etc.) without any previous knowledge or experience.

The "AE-PLC-APS" is composed by two main parts the control panel and the sensor and electropneumatic actuators:

- Control panel: contains all the push-buttons and switches to operate with the unit. The Control panel also contains the differential magnetothermal protection inside the box to perform a safe operation of the unit.

- Sensors and electro-pneumatic actuators: contains all the sensors (reed switches and capacitive sensors), pneumatic actuators (single and double acting cylinders), electro-pneumatic actuators (3/2 and 5/2 solenoid valves) and the remote Ethernet/IP input and output signal required to perform an automatic control of the unit.

- Air treatment unit: contains a filter-regulator block with water trap and shut-off valve, to control the air pressure input to the unit. The air treatment unit contains a double scale manometer to visualize the pressure level supply to the unit.

- Piece feeder module: contains the vertical storage to pile up the pieces. The pieces are supply to the unit one by one through a double acting cylinder. The two inputs of the double acting cylinder have each one an adjustable air flow valve with bypass to regulate the cylinder speed.

- Piece verifier module: is design to detect if the pieces supplied to the unit have or not have a hole in the middle. The piece verifier module check this characteristic to a subsequent sorting of the non-desired pieces, this verification is perform by a double acting cylinder with three sensors. The two inputs of the double acting cylinder have each one an adjustable air flow valve with bypass to regulate the cylinder speed.

- Piece displacer module: is design to move the verified pieces to the classification area, this action is carried out by a double acting cylinder. The two inputs of the double acting cylinder have each one an adjustable air flow valve with bypass and piloted check valve, to regulate the cylinder speed and block the position of the cylinder if there is no air input to the double acting cylinder.

- Piece classification module: is design to sort the pieces, if the piece is good, the classification cylinder is activated and the piece will be pile up at the good piece zone, if the piece is defective the classification cylinder is not activated and the piece will be pile up at the defective pieces classification zone.

- Stack light: is a green, yellow and red led lights to indicate the state of the system.

- Solenoid valves block: is a pneumatic valve manifold block with 5 solenoid valves on it, three 3/2 solenoid valves and two 5/2 solenoid valves.

- Electrical Terminal block: contains all signals of the unit accessible and identified, to check the unit manually. The electrical terminal block has a color coded terminal to help the user to identify the type of each signal, and has the name of each signal.

Cookie preferences

Cookie preferences