12TV Technical and Vocational Education Food Technology Laboratory

INNOVATIVE SYSTEMS

The overall objective to be achieved with the Food Technology Laboratory, "12TV", is to achieve the correct qualification of professionals obtaining a solid scientific training in both basic and more complex aspects applied directly to food.

Expansions

Modules

RELATED NEWS

General Description

The overall objective to be achieved with the Food Technology Laboratory, "12TV", is to achieve the correct qualification of professionals obtaining a solid scientific training in both basic and more complex aspects applied directly to food.

In such a way that allows them to study the nature of food, the causes of its deterioration, the fundamental principles of its processing and its improvement in all phases from production and processing to reach the final consumer.

Therefore, it is intended that in a totally practical way the students of technical training achieve to acquire all the necessary knowledge in Food Technology for their excellent insertion in the working world. Specifically, the specific objectives to be achieved with this Technical Training using EDIBON units are:

- Knowledge of food: study its origin, characteristics, composition and differences.

- Knowledge in food production and processing: to identify the problems associated with different foods and their processing.

- Food safety: establish the prevention and control measures to be taken during the production, processing, transport, distribution and sale of food to ensure safe, genuine, nutritious and suitable products for human consumption.

- Process and product quality management and control: establish procedures and quality controls to achieve maximum quality in the final product avoiding any situation that may contaminate/damage the products.

SUPPLEMENTARY EQUIPMENT

Computer Controlled Deodorizing Unit

Computer Controlled Hydrogenation Unit

Computer Controlled Cheese Vat

Computer Controlled Plate and Frame Filter Press

Computer Controlled UHT Unit

Computer Controlled Teaching Curdling Tank

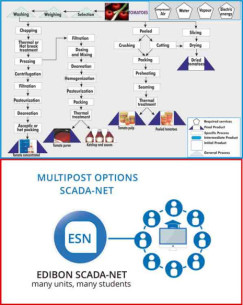

Computer Controlled and Touch Screen Pilot Plants for the Production of Cereals

Computer Controlled Teaching Cream Separator

Computer Controlled Liquid Packaging Teaching Unit

Computer Controlled Butter Maker Teaching Unit

Computer Controlled Teaching Yogurt Incubator

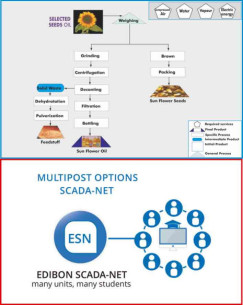

Computer Controlled Continuous Cycle Oil Production Plant

Computer Controlled Teaching Autonomous Pasteurization Unit

Computer Controlled Laboratory Pasteurizer

Computer Controlled Teaching Cheese Press

Computer Controlled Batch Solvent Extraction and Desolventising Unit

Adiabatic and Isothermal Reactor

Tubular Flow Reactor

Isothermal Reactor with Stirrer

Computer Controlled Chemical Reactors Training System

Reactors with Stirrer in Series

Base and Service Unit for QRQC

Computer Controlled Teaching Cottage Cheese Maker

Computer Controlled Reverse Osmosis/Ultrafiltration Unit

Computer Controlled Tray Drier

Computer Controlled Spray Drier

Steam Generator (3 kW)

Steam Generator (6 kW) (for high pressures and high temperatures)

Computer Controlled Contact Plate Freezer

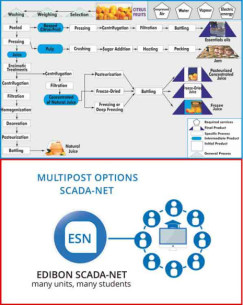

Computer Controlled and Touch Screen Pilot Plant for the Grape Treatment

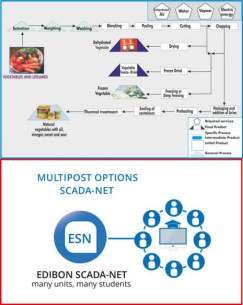

Computer Controlled and Touch Screen Pilot Plant for Vegetables and Legumes

Computer Controlled Multipurpose Processing Vessel

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences