At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

MSLG Unit to Study Lathe Gears

INNOVATIVE SYSTEMS

The Unit to Study Lathe Gears, "MSLG", designed by EDIBON, allows the students to study, understand and identify the different types of gears that these widely-used devices have.

Expansions

RELATED NEWS

General Description

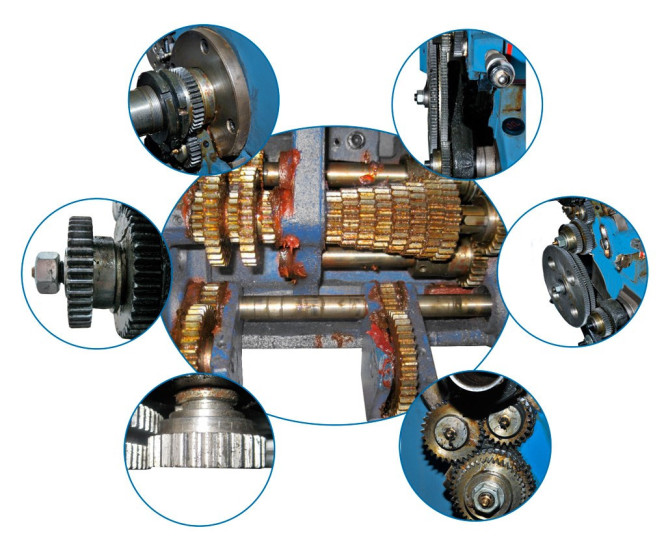

The Unit to Study Lathe Gears, "MSLG", represents the gears of a typical lathe in a machining workshop, including: a main adjustable transmission gear, one Norton gearbox for the machining of specific threads and pitches, a pinion switching gear and a reverse rotation gear.

The part to be machined is represented by an exchangeable cylinder and the cutting tool by a marker. This system allows a dummy test of the machining of the part, the thread pitch and the grinding produced, with the tool post carriage always moving longitudinally.

The unit works using a movable main shaft with three driving pinions of different size, which is driven by means of a graduated handle, and allowing the spindle to change speed. The movement produced in the main shaft is transmitted to the spindle by a gear mesh enabling the reverse rotation. At the same time, the spindle is connected to a Norton gearbox, which conveys the movement to the guide screw, enabling the production of threads of different pitch and the automatic forward movement of the tool post carriage. In parallel, the unit also has an operating lever for the tool post carriage.

Thanks to the lathe gears protective panel, the unit is totally visual and completely safe.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study and understanding of gear operation.

- Analysis, study and understanding of the types of lathe gears.

- Study and understanding of a Norton gearbox.

- Study and understanding of a reverse gear system.

- Study and understanding of a gear switching system.

- Main shaft transmission.

- Tool post threaded shaft operation.

SUPPLEMENTARY EQUIPMENT

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

ADSG

The Drive, Shaft, and Gear Alignment Unit, "ADSG", allows for studying the coupling and uncoupling, maintenance, repair of the related units and checking the operation with the following units:CGA. Combined Gear Assembly Unit.SGA. Spur Gear...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDUC

Computer Controlled Machine Diagnosis Unit

The Computer Controlled Machine Diagnosis Unit, "MDUC", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The Computer...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU

Machine Diagnosis

The family of Machine Diagnosis Unit, "MDU", of Edibon, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The MDU Base Unit, "MDU-UB",...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-MLB

Mobile Structure for MDU

The Mobile Structure for MDU, "MDU-MLB", is a robust structure designed to quickly and easily assemble the various elements of the MDU Base Unit, "MDU-UB" or the Computer Controlled Machine Diagnosis Unit, "MDUC", and thus assemble a mobile test...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SM

Top Table Structure for MDU

A bench-top structure consisting of a slotted table with anodized aluminum frames of 1100 x 770 x 820 mm.It has a transparent protective cover that protects against the rotating parts and allows us to observe the different experiments. The cover...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SSC

Software, Sensors and Control for MDU Unit

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.The system consists of two acceleration sensors, a speed sensor, a measuring amplifier with...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

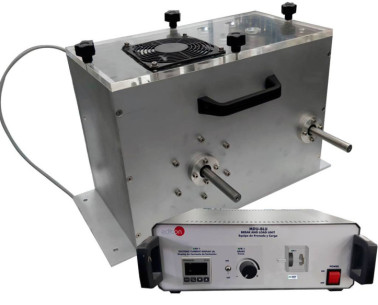

MDU-BLU

Break and Load Unit

The Break and Load Unit, "MDU-BLU", of EDIBON is a magnetic particle brake, a display unit and an electrical control. It is possible to precisely adjust the braking moment. The excitation current is used as a measurement of the braking moment and...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SES

Set of Elastic Shaft

The Set of Elastic Shaft, "MDU-SES", of EDIBON allows to study the behavior of an elastic rotor subjected to imbalance and balance of elastic rotors in operation. It is possible to study the resonance and the phenomena occurred in subcritical and...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SRS

Set of Rotating Shaft with Crank

It is important that fissures resulting from material fatigue in rotating machines are detected in good time before the breakage occurs, which usually leads to fatal consequences.The Set of Rotating Shaft with Crank, "MDU-SRS", consists of two...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SRBF

Set of Roller Bearings with Faults

To determine the remaining life cycle of a roller bearing and decide on its replacement, the slow variation of the vibration spectrum is analyzed. The spectral distribution will enable to draw accurate conclusions about the type of defect and its...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SCO

Set of Couplings

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- INSTALLATIONS AND MAINTENANCE TRAINING

MDU-SBD

Set of Belt Drive

The belt drives are noiseless drive devices, have a long life and require little maintenance provided that its design, assembly and adjustment are correct.The Set of Belt Drive, "MDU-SBD", allows to study the conditions that cause vibrations or...

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences