Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

AE-PLC-MR4 Station de Table Tournante : Remplissage, Embouteillage et Capsulage

SYSTEMES INNOVANTS

The "AE-PLC-MR4" is a rotary table workstation commanded by a PLC that perform the bottling, filling and capping functions.

NOUVELLES LIÉES

Description Générale

The "AE-PLC-MR4" is a rotary table workstation commanded by a PLC that perform the bottling, filling and capping functions.

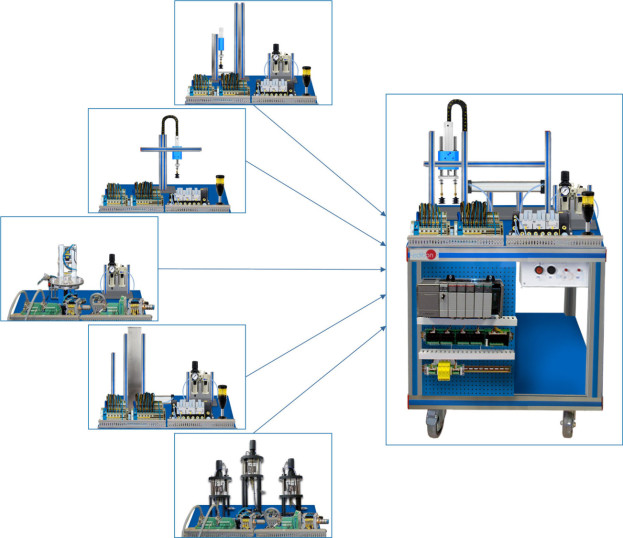

The "AE-PLC-MR4" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed by an AE-PLCB that contains a HMI device, analog and digital input/output modules, etc. and the required extra modules to put into operation the workstation successfully.

- The control panel: emergency stop push button switch, start/stop button, reset button, light indicator to show the state of the workstation, etc.

- The pneumatic circuit: contains the required such as solenoid valves, air filters, air regulators, etc. to assure the appropriate operation of the workstation.

- The workstation: is composed by real components used by the industrial bottling systems such as: IR beam detector, capacitive sensors, pneumatic manipulators, etc.

The "AE-PLC-MR4" workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at the "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR1

The Rotary Table Station: Feeding, Quality Control and Assembly (dimensional study), "AE-PLC-MR1", has been designed by EDIBON to study automatic rotary table systems for mounting, quality control, and feeding parts. It integrates a modular design...

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR2

Station de Table Tournante : Alimentation, Contrôle Qualité et Assemblage (matériau et couleur)

The "AE-PLC-MR2" an automatic rotary table with a feeder, quality control and mounting system integrated in it. The "AE-PLC-MR2" has a vertical storage, the system provide pieces one by one to the rotary table, then, a quality control system check...

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR3

Station de Table Tournante : Contrôle de Traitement Automatisé (étude du perçage et du polissage)

The "AE-PLC-MR3" is a processing workstation with a rotary table commanded by a PLC. This unit takes a piece from the input area, checks if the position of piece is correct, and simulates drilling the piece with a movable drilling machine. Finally...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR1

Station de Table Tournante : Alimentation, Contrôle Qualité et Assemblage (étude dimensionnelle)

The Rotary Table Station: Feeding, Quality Control and Assembly (dimensional study), "AE-PLC-MR1", has been designed by EDIBON to study automatic rotary table systems for mounting, quality control, and feeding parts. It integrates a modular design...

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR2

Station de Table Tournante : Alimentation, Contrôle Qualité et Assemblage (matériau et couleur)

The "AE-PLC-MR2" an automatic rotary table with a feeder, quality control and mounting system integrated in it. The "AE-PLC-MR2" has a vertical storage, the system provide pieces one by one to the rotary table, then, a quality control system check...

6.2.5.3.- POSTES DE TRAVAIL DE LA TABLE ROTATIVE

AE-PLC-MR3

Station de Table Tournante : Contrôle de Traitement Automatisé (étude du perçage et du polissage)

The "AE-PLC-MR3" is a processing workstation with a rotary table commanded by a PLC. This unit takes a piece from the input area, checks if the position of piece is correct, and simulates drilling the piece with a movable drilling machine. Finally...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies