Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

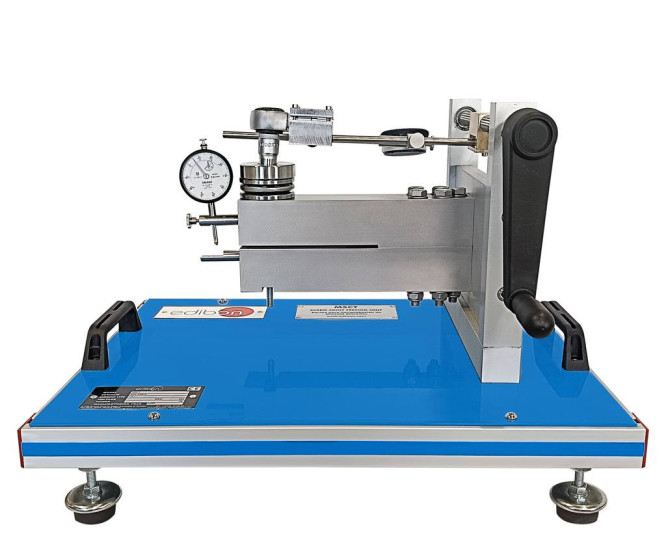

MSCT Unité de Contrôle des Assemblages par Vis

SYSTEMES INNOVANTS

L'Unité de Volant d'Inertie, "MSCT", conçu par EDIBON, est un appareil qui permet de mesurer le couple de serrage d’une vis avec une métrique particulière, qui est liée à une déformation produite dans les deux barres.

Expansions

NOUVELLES LIÉES

Description Générale

L'Unité de Contrôle des Assemblages par Vis, "MSCT", représente la simulation d’un ensemble de serrage composé d’une vis et d’un écrou sur deux poutres de forme rectangulaire.

Une clé dynamométrique très précise effectue le serrage grâce à une tige filetée et un volant d’inertie. La vis et l’écrou joignent deux corps en acier (barres de forme rectangulaire), qui sont séparés à une certaine distance. L’action de la vis et de l’écrou produit une contrainte élastique dans les barres d’acier générée par la tension axiale produite dans le corps de la vis. Le déplacement produit (déformation) est recueilli par un comparateur à cadran permettant l’analyse du couple de torsion avec lequel le serrage a été effectué.

La tête de vis présente une portée axiale qui permet aux frottements d’être négligeables à cet endroit. De cette façon, vous pouvez calculer le frottement du filetage lui-même avec l’écrou.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Étude, définition et compréhension du couple de torsion (effort de serrage).

- Étude, définition et compréhension des déformations élastiques dans les poutres.

- Analyse et étude du frottement dans le filetage de la vis.

- Calcul de la force axiale exercée par la vis et l’écrou, en fonction du couple de serrage.

- Calcul de la force axiale exercée par la vis et force en fonction de la déformation élastique.

EQUIPEMENT COMPLEMENTAIRE

7.4.3.- INSTALLATIONS ET MAINTENANCE

ADSG

L’Unité d’Alignement des Entraînements, Arbres et Engrenages, "ADSG", permet d’étudier l’accouplement et le désaccouplement, l’entretien, la réparation des unités associées et de vérifier le fonctionnement avec les unités suivantes:CGA. Unité...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDUC

Unité de Diagnostic de Machine, Contrôlée par Ordinateur (PC)

L´Unité de Diagnostic de Machine, Contrôlée par Ordinateur (PC), "MDUC", d’EDIBON permet de réaliser des pratiques de mesure des vibrations, en mesurant le déplacement, la vitesse et l’accélération des vibrations dans la gamme...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU

Diagnostic des Machines

La famille des unités de Diagnostic Machine "MDU", d’EDIBON permet de réaliser des pratiques de mesure des vibrations, en mesurant le déplacement, la vitesse et l’accélération des vibrations dans la gamme temps-fréquence.Les composants de l’unité...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-MLB

Structure Mobile pour MDU

L’Structure Mobile pour MDU, "MDU-MLB", est une structure robuste permettant d’assembler rapidement et facilement les différents éléments de l’unité de base MDU, "MDU-UB", ou de l’Unité de Diagnostic de Machine, Contrôlée par Ordinateur (PC),...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SM

Structure de la Table Supérieure pour Le MDU

Structure du plateau composée d’une table à fentes avec des profils en aluminium anodisé mesurant 1100 x 770 x 820 mm.Il est doté d’un couvercle de protection transparent qui protège les pièces en rotation et permet d’observer les différentes...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SSC

Logiciels, Capteurs et Contrôle pour l'Unité MDU

Le Logiciels, Capteurs et Contrôle pour l’Unité MDU, "MDU-SSC", permet d’effectuer toutes les mesures et analyses de vibrations.La fonction de l’analyseur de vibrations est d’évaluer les tests de diagnostic des machines avec les différents...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-BLU

Unité de Freinage et de Chargement

L’Unité de Freinage et de Chargement, "MDU-BLU", d’EDIBON est un frein à particules magnétiques et une unité d’affichage et de commande électronique. Il est possible d’ajuster précisément le couple de freinage en générant une charge résistante. Le...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SES

Ensemble de l'Arbre Élastique

Le Ensemble de l’Arbre Élastique, "MDU-SES", d’EDIBON permet d’étudier le comportement d’un rotor élastique soumis à un déséquilibre et l’équilibrage de rotors élastiques en fonctionnement. Il est possible d’étudier la résonance et les phénomènes...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SRS

Ensemble d’Arbres avec Fissures

Il est important de détecter à temps les fissures dues à la fatigue des matériaux dans les machines tournantes avant qu’elles ne se brisent, ce qui a souvent des conséquences fatales.Le Jeu d’Arbres Tournants Avec Manivelle, "MDU-SRS", contient...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SRBF

Ensemble de Défauts dans les Roulements

Afin de déterminer la durée de vie restante d’un roulement et de décider de son remplacement, la variation lente du spectre de vibration est analysée. La distribution spectrale permet de tirer des conclusions précises sur le type de défaut et sa...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SCO

Ensemble d’Accouplements

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- INSTALLATIONS ET MAINTENANCE

MDU-SBD

Ensemble de Transmission par Courroie

Les transmissions par courroie sont des dispositifs d’entraînement silencieux, durables et nécessitant peu d’entretien, à condition qu’elles soient correctement conçues, assemblées et réglées. Le Jeu de Courroies de Transmission, "MDU-SBD", permet...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies