THARA2C/1 Unité de Méthodes de Contrôle de la Capacité de Refroidissement, Contrôlée par Ordinateur (PC)

SYSTEMES INNOVANTS

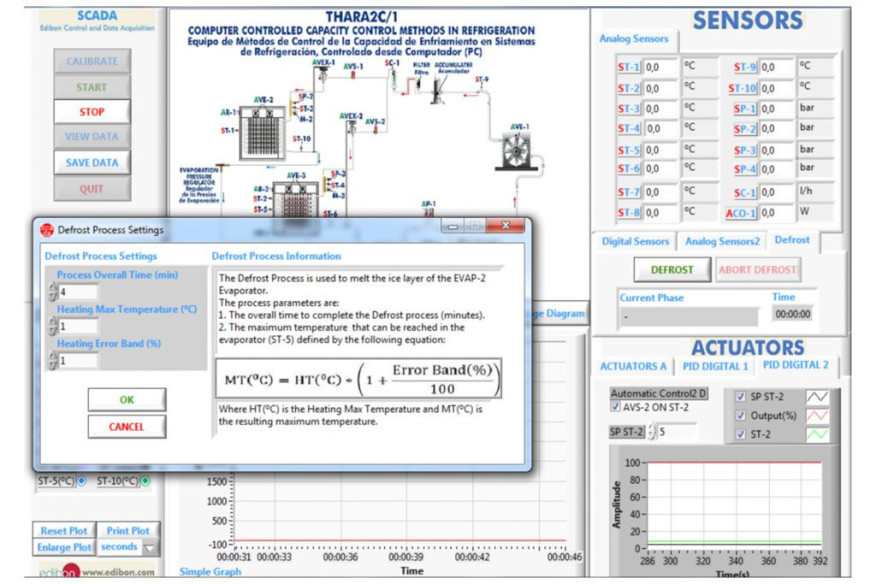

The Computer Controlled Capacity Control Methods in Refrigeration, "THARA2C/1", allows to study and to investigate several methods of capacity control.

Expansions

Laboratories

NOUVELLES LIÉES

Description Générale

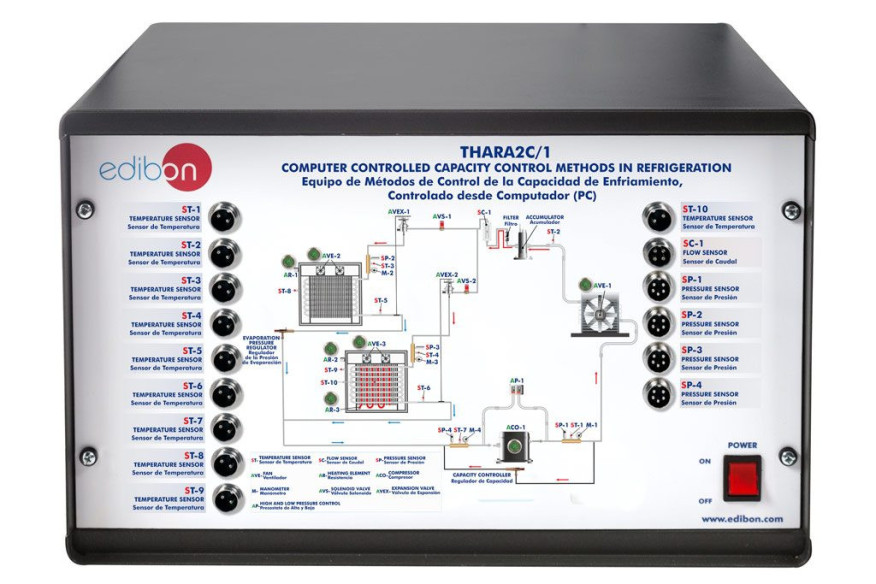

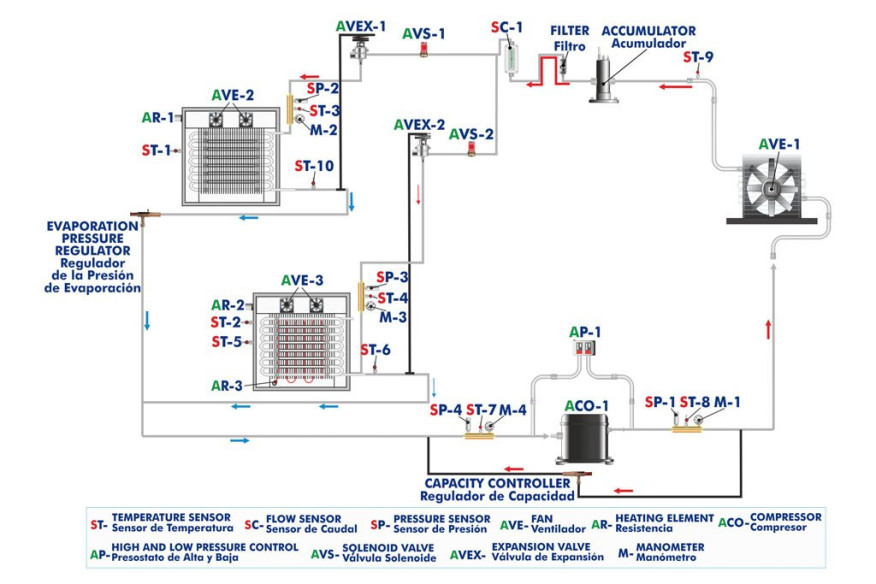

The Computer Controlled Capacity Control Methods in Refrigeration, "THARA2C/1", allows to study and to investigate several methods of capacity control. For this purpose a refrigeration circuit with two refrigeration chambers is available in which a cooling load is generated using adjustable heating elements. Several fans in both refrigeration chambers ensure an even temperature distribution.

The refrigeration capacity of the refrigeration can be adjusted via the speed of the compressor (computer controlled). There also is the option to adjust the refrigeration capacity with the capacity controller situated in the compressor bypass. The unit includes a computer controlled air condenser, two evaporators in insulated refrigeration chambers, an accumulator, a filter, a flow sensor and a high and low pressure control. Each refrigeration chamber includes an adjustable heating element (computer controlled), a thermostatic expansion valve, a sight glass and a set of fans (computer controlled).

In the first refrigeration chamber (refrigeration) a solenoid valve (computer controlled) and an evaporation pressure regulator control the flow and the pressure of the coolant in the evaporator of the chamber and thereby the temperature.

In the second refrigeration chamber (freezing) a solenoid valve (computer controlled) control the flow of the coolant in the evaporator of the chamber and thereby the temperature. This refrigeration includes a check valve and a defrost heating element (computer controlled).

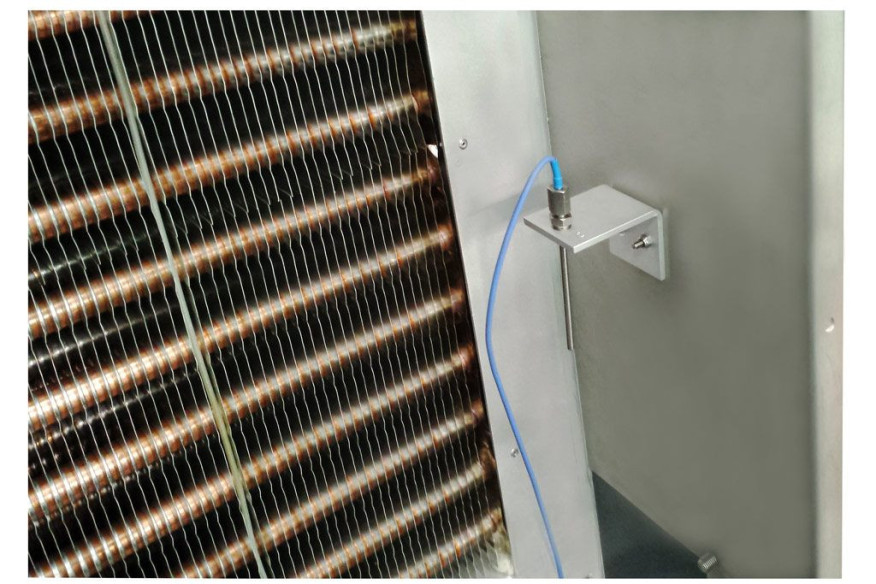

Both refrigeration chambers feature a window to be able to monitor the fans operation and formation of ice.

A flow sensor measures the coolant flow at the inlet of the refrigeration chambers, and several temperature sensors record the temperature of the coolant upstream and downstream of the evaporators and inside of the refrigeration chambers. Manometers and pressure sensors enable the easy reading of pressures at the relevant points.

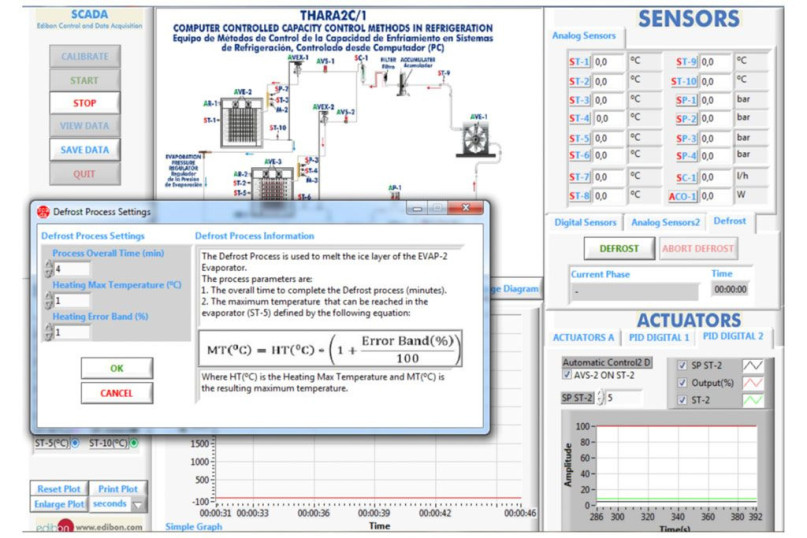

Two PID controls enable constant temperature operation by controlling the open or close of the solenoid valves.

The software incorporates a "Defrost Process" to defrost the layer of frost of the second refrigeration chamber (freezing).

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Study of refrigeration circuit with two evaporators.

- Study of the effect of the compressor speed on the system refrigeration capacity.

- Study of the effect of the evaporation pressure regulator on the system refrigeration capacity.

- Study of the effect of the capacity controller on the system refrigeration capacity.

- Study of a refrigeration controller with specification of temperatures for switching on and off of the defrost heater.

- Sensors calibration.

PLUS D'EXERCICES PRATIQUES À EFFECTUER AVEC CETTE ÉQUIPEMENT

- Properties of the refrigerant R-513a.

- Enthalpy-Pressure diagram for the refrigerant R-513a.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the THARA2C/1 unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the THARA2C/1 unit process.

- Several other exercises can be done and designed by the user.

EQUIPEMENT COMPLEMENTAIRE

Tour de Refroidissement de bureau

Unité de Démonstration du Cycle de Réfrigération, Contrôlée par Ordinateur (PC)

Unité de Démonstration du Cycle de Réfrigération

Unité de Réfrigération par Absorption, Contrôlée par Ordinateur (PC)

Unité de réfrigération par absorption

Unité de Régulation de la Puissance et des Défauts dans les Installations de Réfrigération, Contrôlée par Ordinateur (PC)

Unité de Réfrigerateur Vortex, Contrôlée par Ordinateur (PC)

Pompe à Chaleur Thermoélectrique, Contrôlé par Ordinateur (PC)

Unité de Circuit de Réfrigération par Compression

Réversible Pompe à Chaleur + Climatisation + Réfrigération avec 2 condenseurs et 2 évaporateurs (d'eau/ d'air), Contrôlé par Ordinateur (PC)

Réversible Pompe à Chaleur + Climatisation + Réfrigération avec 2 condenseurs et 2 évaporateur (d'eau/d'air)

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies