Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

AE-PLC-CTCA Usine-école de Bande Transporteuse CA

SYSTEMES INNOVANTS

NOUVELLES LIÉES

Description Générale

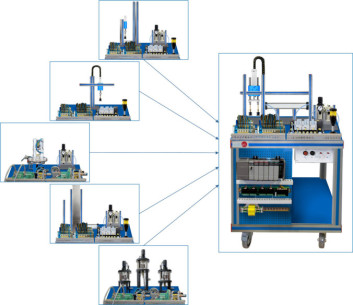

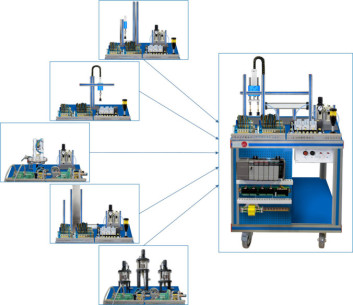

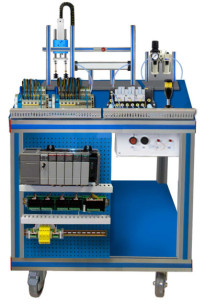

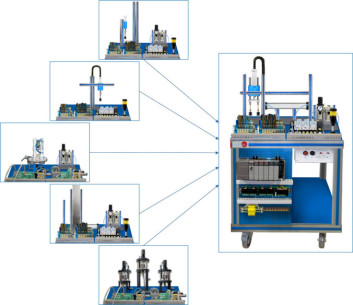

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a complete control of the conveying.

The "AE-PLC-CTCA" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The workstation: is composed by real components used by the industrial automatic conveyor systems such as: capacitive sensors, limit switch sensors, position sensor, etc.

The "AE-PLC-CTCA" workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Introduction to flexible manufacturing system (FMS).

- Study of the sensor detection.

- Manual control of an AC conveyor.

- Automatic control of an AC conveyor.

- Change the parameters of the conveyor system.

- Optimize the process time.

- Study the faults inserted in the process with the fault generation module.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAE

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAN

Usine-école Pneumatique de Manipulation

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MPS

Usine-école de Manipulation des Pièces

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-T

Usine-école de Transport Linéaire

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-SPO

Usine-école de Positionnement

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCC

Usine-école de Bande Transporteuse CC

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MACT

Usine-école Pneumatique de Manipulation et Bande Transporteuse

Le Station de Manutention Pneumatique et Ruban de Transportn, "AE-PLC-MACT" est une station de manutention automatique avec système de convoyeur commandé par un PLC. Le "AE-PLC-MACT" est composé d'un système de manutention pneumatique qui utilise...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MPS

Usine-école de Manipulation des Pièces

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-T

Usine-école de Transport Linéaire

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-SPO

Usine-école de Positionnement

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAE

Usine-école Électrique de Manipulation

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAN

Usine-école Pneumatique de Manipulation

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCC

Usine-école de Bande Transporteuse CC

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MACT

Usine-école Pneumatique de Manipulation et Bande Transporteuse

Le Station de Manutention Pneumatique et Ruban de Transportn, "AE-PLC-MACT" est une station de manutention automatique avec système de convoyeur commandé par un PLC. Le "AE-PLC-MACT" est composé d'un système de manutention pneumatique qui utilise...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies