Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

AE-PLC-ALB Usine-école de Stockage pour Boîtes

SYSTEMES INNOVANTS

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z.

NOUVELLES LIÉES

Description Générale

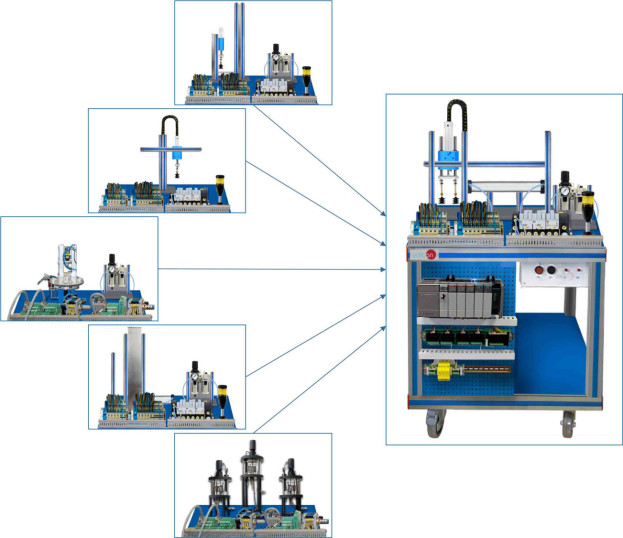

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup that is used to catch and release bottles. The function of the workstation is to catch bottles in the input area, and release each bottle in the programmed position of a numbered pallet.

The "AE-PLC-ALB" workstation has been designed as a modular system to facilitate the understanding of the equipment operation:

- The PLC: is composed by an AE-PLCB that contains a HMI device, analog and digital input/output modules, etc, and the required extra modules to put into operation the workstation successfully.

- The control panel: emergency stop push button switch, start/stop button, reset button, light indicator to show the state of the workstation, etc.

- The pneumatic circuit: contains the required such as solenoid valves, air filters, air regulators, etc. To assure the appropriate operation of the workstation.

- The workstation: is composed by real components used by the industrial automatic storage bottling systems such as: IR beam detector, capacitive sensors, servomotor controllers, manipulators with vacuum technology, etc.

The "AE-PLC-ALB" workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at the "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-ALT

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.The...

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-AL

Usine-école de Stockage

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-ALV

Usine-école de Stockage Vertical

Le Usine-école de Stockage Vertical, "AE-PLC-ALV", conçue par EDIBON, est une usine-école de travail de stockage automatique contrôlée par un PLC qui vérifie le matériau et les dimensions des pièces entrantes pour les classer dans le stockage...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-AL

Usine-école de Stockage

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-ALT

Usine-école de Stockage Temporaire

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.The...

6.2.5.8.- STATIONS DE TRAVAIL DE STOCKAGE DE PIÈCES

AE-PLC-ALV

Usine-école de Stockage Vertical

Le Usine-école de Stockage Vertical, "AE-PLC-ALV", conçue par EDIBON, est une usine-école de travail de stockage automatique contrôlée par un PLC qui vérifie le matériau et les dimensions des pièces entrantes pour les classer dans le stockage...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies