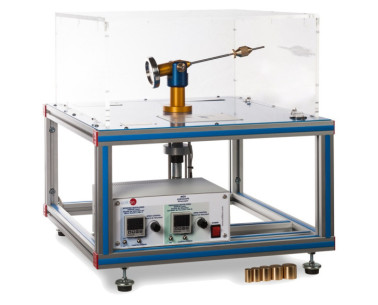

The Cam Analysis Unit "MEAL" allows to observe the effect of the profile of a cam, the study of the displacement, velocity and acceleration profiles of the cam and the identification of the factors that can modify the dynamics of the cam.

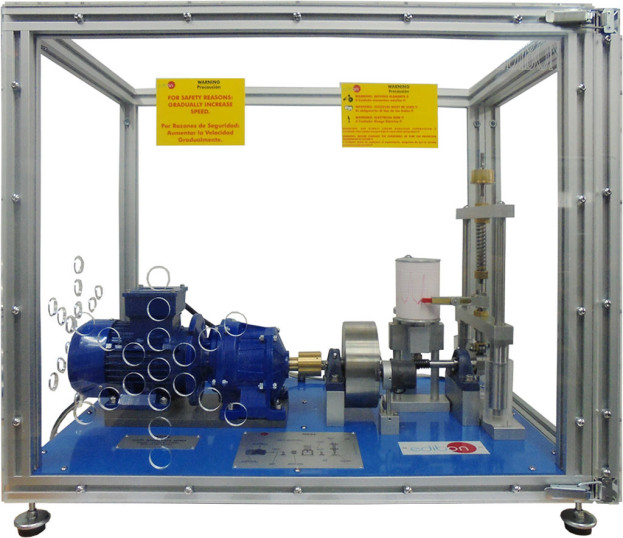

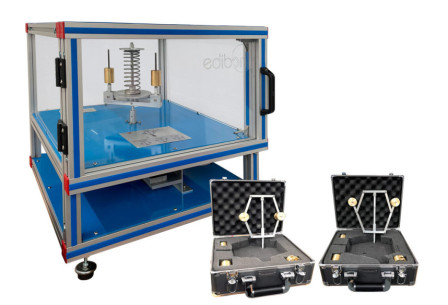

This unit consists of a motor, an extension shaft, a set of interchangeable cams, several different followers, a set of springs and weights and a drum recording system to register the lifting and displacement of the cam.

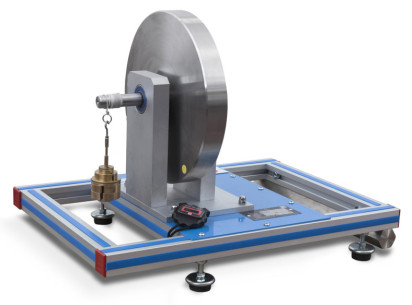

The motor is coupled to an extension shaft that allows to rotate the cams. The cams are easily mounted at the end of the fixed shaft. A large intertia mass is connected between the motor and the cam to guarantee a constant operation at several speeds.

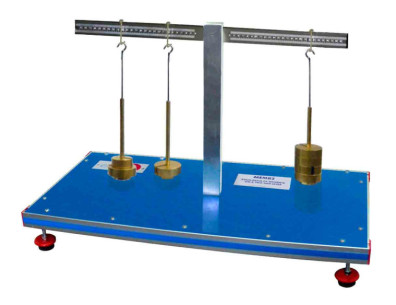

The follower is coupled to a shaft that moves vertically and includes weights and springs, employed to simulate a valve. The upper end of the spring surrounds the vertical shaft. The compression spring will push the follower on the face of the cam.

The stress of the spring and the inertia of the follower can be modified using different weights. Several interchangeable springs are supplied to change the operation of the valve and its response. To demonstrate the "oscillation of the valve", the springs, the weights and the velocity can be modified.

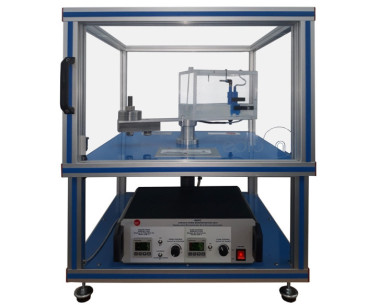

The tracer draws a register of the lifting and displacement of the cam on a piece of paper (displacement curves) using the drum recording system.

The paper is attached to a cylindrical drum register to represent the motion of the cam.

The design guarantees that the elements of the unit can be observed during the motion process. For that purpose, a transparent safety cover is fitted over the unit.

A speed sensor measures the speed of the motor during the practical exercises.The unit includes a console with a digital screen to show the speed of the motor.

Preferensi cookie

Preferensi cookie