QRALC Reaktor Airlift, Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

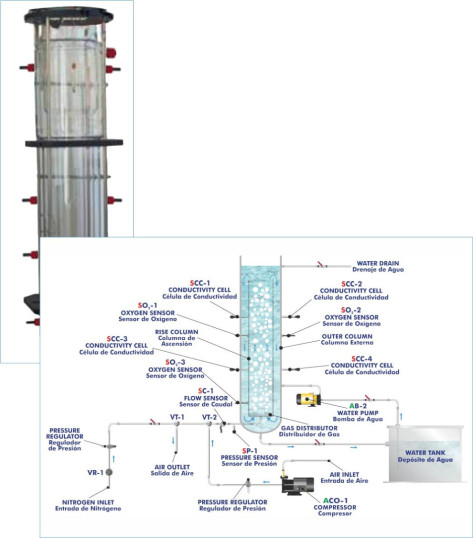

The Computer Controlled Airlift Reactor, "QRALC", is an aerobic submerged reactor designed to determine the characteristic variables of the airlift reactor. It is made of transparent material so that the internal recirculation can be visualized.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Airlift Reactor, "QRALC", is an aerobic submerged reactor designed to determine the characteristic variables of the airlift reactor. It is made of transparent material so that the internal recirculation can be visualized.

The airlift reactor comprises an outer column (the reactor column), a riser column and a gas-liquid separator.

The riser column is placed concentrically inside the reactor column.

The annular space between the riser and reactor columns forms the downcomer section of the reactor.

The bottom of the reactor column is sealed with a membrane. There is a gas distributor to feed air or nitrogen to the reactor. Compressed air is fed into the reactor through the capillaries of the gas distributor, positioned at the center of the reactor, to generate air bubbles and recirculate the reactor contents. The superficial gas velocity in the reactor is adjusted and controlled using a valve and a flow sensor.

The superficial liquid velocity is measured with several conductivity sensors situated at different levels of the reactor.

Compressed air enters the reactor at the bottom and ascends in the riser column as small air bubbles. The water moves upwards due to the lower density of the water/air mixture. The air bubbles leave the water at the head of the reactor. Due to the higher density, the water with the dissolved oxygen sinks again.

To determine the mass transfer coefficient of oxygen in water, nitrogen can be fed to the bottom of the reactor to remove the oxygen from the reactor content.

The unit includes a tank to store water, a centrifugal pump to supply water to the reactor, an air compressor, two pressure regulators, four conductivity sensors, three oxygen concentration sensors, a pressure sensor and a flow sensor.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

,

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Study of the influence of the superficial gas velocity on the mixing time and superficial fluid velocity.

- Study of the influence of the superficial gas velocity on the mass transfer coefficient.

- Study of the influence of the superficial gas velocity on the gas content.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QRALC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QRALC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Reaktor dengan Rekirkulasi untuk Media Korosif 250L, Dikendalikan dari Komputer dan Layar Sentuh

Sistem Pelatihan Reaktor Kimia, Dikendalikan dari Komputer (PC)

Unit Dasar dan Layanan untuk QRQC

Reaktor Isotermal dengan Pengaduk

Reaktor Isotermal dengan Pengaduk dan Distilasi

Reaktor Aliran Pipa

Reaktor Pengaduk Seri

Reaktor Adiabatik dan Isotermal

Reaktor Kimia, Dikendalikan dari Komputer (PC)

Unit Dasar dan Layanan untuk QRC

Reaktor Tangki Pengaduk Kontinu untuk QRC, Dikendalikan dari Komputer (PC)

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie