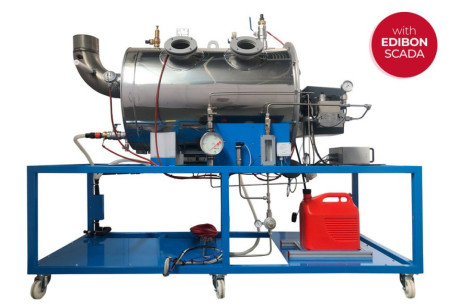

TCESC Computer Controlled Separating and Throttling Calorimeter

SISTEM INOVATIF

The Computer Controlled Separating and Throttling Calorimeter, "TCESC", makes it possible to determine the content of water in the wet steam, both in big and small quantities.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Separating and Throttling Calorimeter, "TCESC", has been designed to determine the steam humidity content and the dryness fraction of steam.

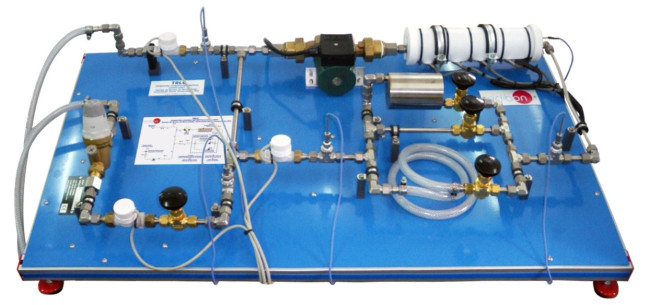

This unit works with steam. The steam is introduced into the line by means of a computer controlled solenoid valve. This line has a safety valve to relieve pressure and a pressure switch.

The steam enters the separating calorimeter, the pressure and temperature variables being measured beforehand, the separation of the incoming wet steam is performed by changing the flow direction through a series of obtuse angles, causing the remaining droplets to fall into the tank and the steam with less humidity to continue, where temperature and pressure are measured again. The separating calorimeter is used for a direct determination of great quantities of water (up to x=0.5).

The temperature of the separated water remaining in the tank is measured and passed to the condenser, where it is cooled by a coiled heat exchanger, the condensed water is collected in a vessel where its weight is measured. The inlet and outlet temperatures of the heat exchanger are measured for both the separate water and the cold water. A flow sensor determines the cold water flowing through the exchanger to study the heat transfer between the condensate of the calorimeter (hot water flowing through a coil) and the cold water flowing through the exchanger.

The remaining steam arrives at a throttle valve where there is a decrease in temperature due to the sudden drop in pressure, the vapor reaches the expansion chamber of the throttle calorimeter, where temperature and pressure are measured. This calorimeter is used for small moisture contents (the quality of the steam is between 0.95 and 1.0) and can be determined using the diagram h, s.

This steam passes to the other condenser, where it is cooled by a coiled heat exchanger, the condensed water is collected in a vessel, where its weight is measured.

The cold water flows can be regulated by means of a valve.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- To use a separating calorimeter for high water contents.

- To use a throttling calorimeter for high vapor contents.

- The steam fraction and the quality of the steam through the separating and throttling calorimeters.

- The global energy balance in the exchanger and the study of losses.

- The exchanger efficiency. NTU method.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TCESC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TCESC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Thermal Expansion Training Unit

Computer Controlled Expansion Processes of a Perfect Gas Unit

Bomb Calorimeter

Computer Controlled Marcet Boiler Unit

Computer Controlled Temperature Measurement Unit

Temperature Measurement Unit

Temperature Measurement Training Unit

Computer Controlled Gas Laws Unit (Boyle and Gay-Lussac Laws)

Computer Controlled Recycle Loops Unit

Recycle Loops Unit

Computer Controlled Saturation Pressure Unit

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie