Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st...

Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st century, its availability and quality are increasingly at risk. Population growth, industrial and agricultural pollution, water scarcity in vulnerable...

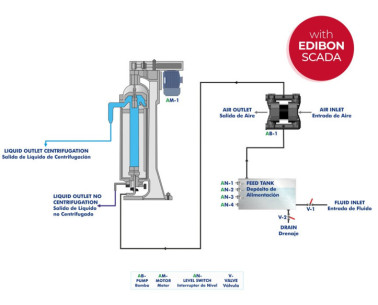

In a world where climate change represents one of the greatest threats to our future, carbon dioxide (CO2) adsorption has become an urgent priority. The increasing concentration of CO2 in the atmosphere, primarily driven by human activities such as fossil fuel combustion and deforestation, has...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

Direct Air Capture (DAC) adalah teknologi inovatif yang menghilangkan CO₂ langsung dari udara menggunakan reaksi kimia dengan pelarut cair atau penyerap padat. Meskipun menghadapi tantangan seperti biaya tinggi dan konsumsi energi, DAC menawarkan solusi potensial untuk mengurangi konsentrasi CO₂...

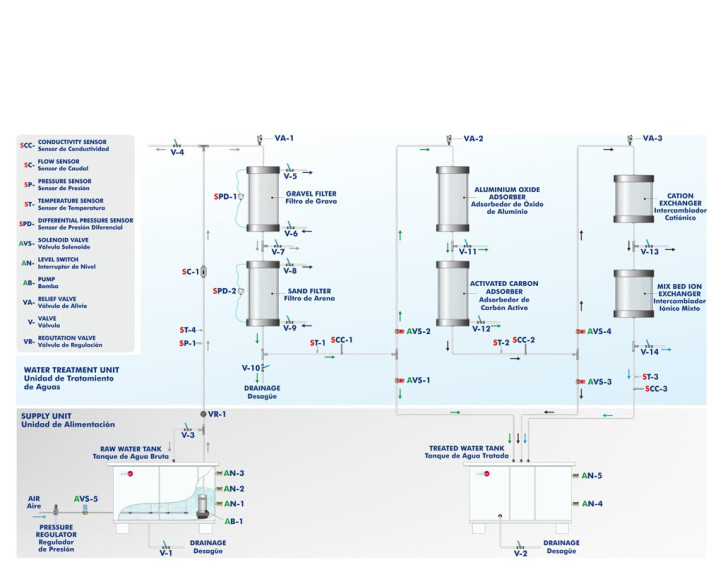

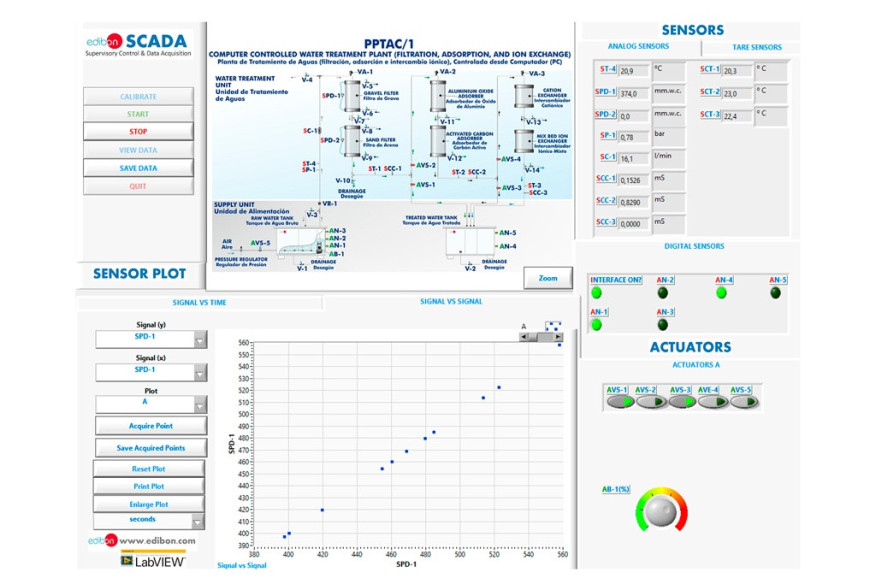

Instalasi Pengolahan Air Limbah

Sementara pabrik pengolahan air minum berfokus pada penyediaan air minum yang aman, instalasi pengolahan air limbah menangani pengolahan air bekas sebelum dilepaskan kembali ke lingkungan.

Instalasi ini memainkan peran penting dalam melindungi sumber daya air dan...

We have returned to the Cfmi_togo to install some of our equipment. These units belong mainly to the areas of Environment, Chemical Engineering, Thermodynamics & Thermotechnics, Energy and Mechanics.

We recently had the honor of installing a complete laboratory at the Centre de formation et des métiers (CFMI) in Togo (Africa).This complete laboratory now has the following EDIBON units

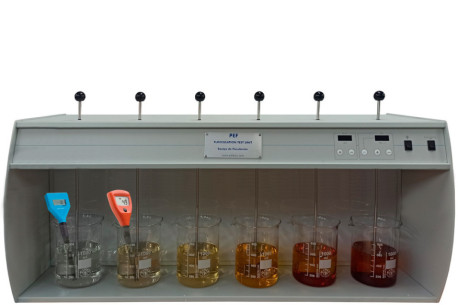

Food Technology is a branch of Food Science based on multidisciplinary knowledge of nutrition, chemical analysis, physics, biochemistry and engineering. Water treatment technologies obtain drinking water, so necessary for our life.

Both disciplines have become in recent years an indispensable...

Preferensi cookie

Preferensi cookie