UV00 Pabrik Pilot untuk Pengolahan Anggur, Dikendalikan dari Komputer (PC) dan Layar Sentuh

SISTEM INOVATIF

The Computer Controlled and Touch Screen Pilot Plant for the Grape Treatment, "UV00", designed by EDIBON, is a pilot plant in which the main production processes related to grapes are carried out.

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

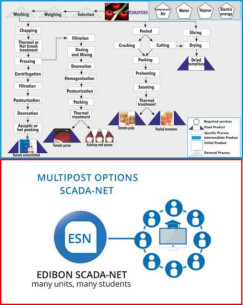

The Computer Controlled and Touch Screen Pilot Plant for the Grape Treatment, "UV00", designed by EDIBON, is a pilot plant in which the main production processes related to grapes are carried out.

- GD/CTS. Computer Controlled and Touch Screen Grape Destemming Unit: The first step in the treatment of the grapes is the washing and the destemming, a process in which dirt, dust and scrapings are removed from the bunches, as well as a light pressing (a process that is carried out in the destemmer).

- TMVF. Two Tanks for Maceration, Vatting and Fermentation of Wine: The next step in the production of wine is the vatting of the must produced during approximately 6 days as the first step of fermentation, this process is not carried out if the final product is juice.

- HGP/CTS. Computer Controlled and Touch Screen Hydraulic Grape Press: Subsequently, the product coming from the destemmer is introduced into a press, where a liquid and filtered product is obtained. The use of a press increases the productivity of the process by being able to obtain a greater quantity of liquid that is not retained in the pomace.

- TERA. Refrigeration or Heating Water Recirculation Unit: For the elaboration of the juice, after pressing, a conditioning and sterilization process would be carried out before proceeding to its bottling or concentrate. In winemaking, the must obtained after pressing must be stored under controlled conditions, 15 °C and a relative humidity between 60 % and 80 %.

- EDLC. Computer Controlled Liquid Packaging Teaching Unit: Storage may be in barrels or directly into the bottle. This pilot plant incorporates a bottling machine equipped with a filter to remove any impurities it may contain.

These units are supplied with EDIBON's own designed SCADA + PLCHMI (system composed of an interface including PLC as the CPU, digital I/O module, analog I/O module, communication module, etc. and a control box with HMI display) to control the whole process and all the parameters involved in the bottling process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Study of the grape destemming process.

- Calculation of the weight of impurities and stems in grape bunches.

- Influence of the speed of rotation in the destemming process.

- Influence of roller adjustment on grape pressing.

- Study of the operation of a hydraulic system.

- Study of grape pressing in a hydraulic press.

- Study of the influence of the working pressure on the grape pressing.

- Calculation of the pressing efficiency.

- Study of the influence of the type of grape on the must yield.

- Study of wine filtration.

- Study of the influence of fermentation time on the final product.

- Study of the influence of fermentation temperature on the final product.

- Calculation of the alcohol content of wine.

- Study of the operation of a plate filter.

- Study of the pressure drop in a plate filter.

- Study of the bottle filling process.

- Study of the operation of a by-pass regulation system.

- Study of the wine maceration process.

- Study of the wine racking process.

- Study of the process of vatting, devatting and bleeding of wine.

- Study of the influence of the maceration temperature on the must.

- Study of the influence of the vatting temperature on the must.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. Each unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc. in real time.

- Each unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- Each unit can be used for doing applied research.

- Each unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Visualization of all the sensors values used in the UV00 pilot plant process.

- Several other exercises can be done and designed by the user.

PERALATAN SIMILAR TERSEDIA

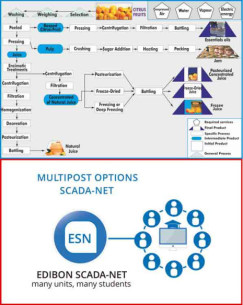

Pabrik Pilot untuk Buah Jeruk, Dikendalikan dari Komputer (PC) dan Layar Sentuh

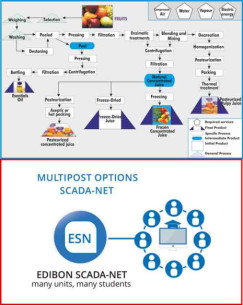

Pabrik Pilot untuk Sayuran dan Kacang-kacangan, Dikendalikan dari Komputer (PC) dan Layar Sentuh

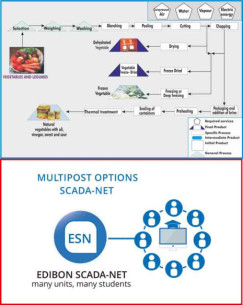

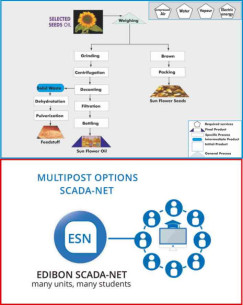

Pabrik Pilot untuk Minyak Biji, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pabrik Pilot untuk Produksi Minyak, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pabrik Pilot untuk Tomat, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pabrik Pilot untuk Produksi Sereal, Dikendalikan dari Komputer (PC) dan Layar Sentuh

PERALATAN KOMPLEMENTER

Pabrik Pilot untuk Produksi Jus Pasteurisasi

Pabrik Pilot untuk Produksi Puree dan Pasta Buah

Pabrik Pilot untuk Produksi Esens Buah

Pabrik Percobaan untuk Produksi Saus atau Pencampur Buah

Pabrik Pilot untuk Produksi Selai Buah

Pabrik Pilot untuk Produksi Sari Konsentrat

Pabrik Pilot untuk Buah Jeruk, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pabrik Pilot untuk Tomat, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pabrik Pilot untuk Sayuran dan Kacang-kacangan, Dikendalikan dari Komputer (PC) dan Layar Sentuh

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie