PASC Pasteurizer Laboratorium, Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

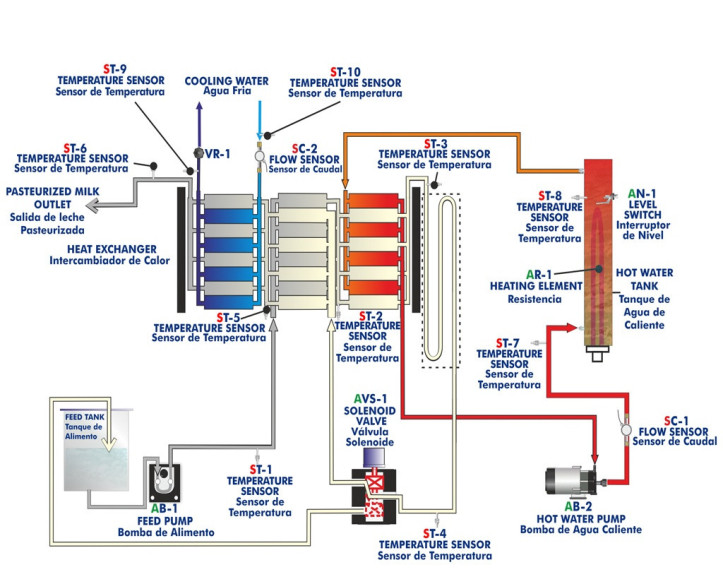

The Computer Controlled Laboratory Pasteurizer, "PASC", is a small scale continuous flow pasteurizer designed by EDIBON. It performs HTST pasteurization (High Temperature Short Time), which simulates the working conditions of a real plant. Nevertheless, small amounts of product can be pasteurized in a short period, resulting in an economical unit whose operation is easy to understand for students.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Laboratory Pasteurizer, "PASC", allows continuous flow conditions with flow rates between 1 and 30 l of product per hour. Temperatures up to 90 °C can be obtained and residence times and efficiencies can be changed. The main element of the Laboratory Pasteurizer is its plate heat exchanger. It is divided into three sectors, for heating, interchanging and cooling.

A series of pasteurization process stages can be distinguished:

- A first stage where the preheating of the food product is realized.

The Pasteurizer receives the product from the feed tank and preheats it in the central section (interchanging) of the heat exchanger, by crosscurrent circulation with the pasteurized and hot product.

- Then, the product flows to a second heating stage where the temperature of the product is increased to a value enough to eliminate the high microorganisms (72° C approximately), during a holding time.

This heating stage is obtained by circulating the product crosscurrent with the hot water from the tank where there is a heating element.

The product is kept at the pasteurization temperature during 15 – 20 seconds in the retention section.

- Instead of the pasteurized product going out at 72 °C, it is made to circulate crosscurrent with the incoming product at 4 °C, so a double effect is obtained:

Energy savings when preheating the incoming product from the initial temperature of 4 °C to 56 °C. The efficiency in the energy recuperation process can reach 75 %.

Outlet of the pasteurized product at the temperature of 40 °C, which helps the last stage.

- The last stage in the heat exchanger is to process the cooling of the product for its conservation. To do this, the product is passed through the last heat exchanger sector by crosscurrent circulation with the cold water.

The Computer Controlled Laboratory Pasteurizer, "PASC", also allows the student to become familiar with a cleaning process known as CIP (Clean In Place) and is automatically carried out by sectors, as it is in real pasteurization plants.

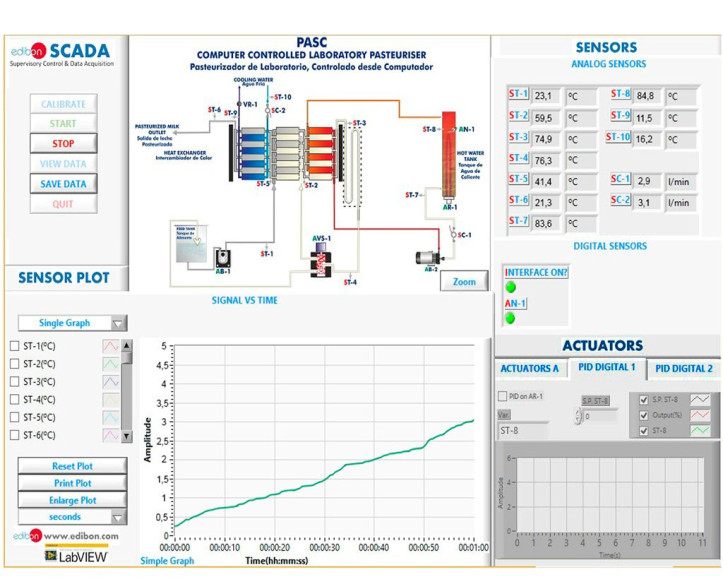

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Study of the HTST pasteurization of alimentary products.

- Study of the destruction of damaging organisms.

- Calibration of the peristaltic feed pump.

- Start of the pasteurization plant, operation with water.

- Determination of the relation between the heating water temperature according to the liquid flow to pasteurize.

- Determination of the survival curve for the different bacterial floras.

- Determination of the threshold temperature for a constant warming time of the product to treat.

- Determination of the necessary time to obtain a desired sterility volume.

- Determination of the thermal reduction time curve.

- Study and application of the CIP cleaning of the pasteurizer.

- Study of different chemical cleaning methods.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control.This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PASC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PASC unit process.

PERALATAN SIMILAR TERSEDIA

PERALATAN KOMPLEMENTER

Pemisah Krim Didaktik, Dikendalikan dari Komputer (PC)

Pemisah Krim Edukasi

Peralatan Didaktik untuk Pembuatan Mentega, Dikendalikan dari Komputer (PC)

Peralatan Didaktik untuk Pembuatan Mentega

Peralatan UHT, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Pasteurisasi Didaktik Mandiri, Dikendalikan dari Komputer (PC)

Bak Koagulasi Didaktik, Dikendalikan dari Komputer (PC)

Pencetak Keju Didaktik, Dikendalikan dari Komputer (PC)

Wadah Pembuatan Keju Gaya Belanda (hingga 50 liter)

Inkubator Yoghurt Didaktik, Dikendalikan dari Komputer (PC)

Pembuat Dadih Didaktik, Dikendalikan dari Komputer (PC)

Wadah Pembuatan Keju, Dikendalikan dari Komputer (PC)

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie