TEPGC Peralatan Proses Ekspansi Gas Ideal, Dikendalikan dari Komputer (PC)

SISTEM INOVATIF

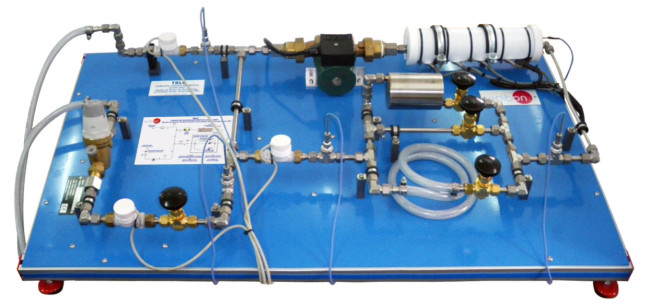

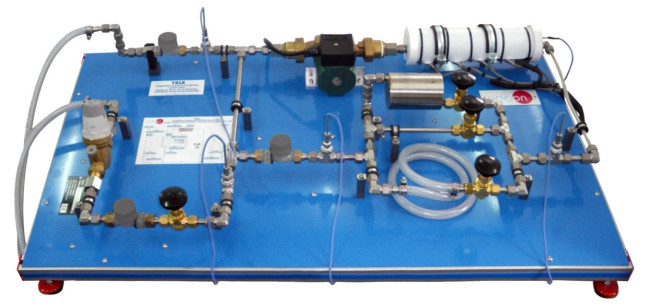

The "TEPGC" is a unit designed to demonstrate the expansion and compression processes of a perfect gas and the basic principles of thermodynamics.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The "TEPGC" is a unit designed to demonstrate the expansion and compression processes of a perfect gas and the basic principles of thermodynamics.

The unit consists of two rigid vessels connected to each other. They are made of methacrylate to facilitate the visualization of the experiments and to thermally isolate their content from the external conditions. One of them works under pressure and the other under vacuum conditions.

There is a computer controlled air pump between both vessels. It includes pipes and valves that will be activated to select the different experiments. One of the objectives of the pump will be to pressurize the pressurized vessel with air and remove the air from the vacuum vessel.

A pressure sensor, a temperature sensor and a gauged overpressure safety valve are mounted on the upper cover of the pressurized vessel.

The capacity of the vacuum vessel is smaller compared to the other. There is a pressure sensor and a temperature sensor on its upper cover.

Both vessels are interconnected by two pipes of different section: a large diameter pipe that separates both vessels through a quick-acting valve, which will enable quick gas expansions, and a smaller diameter pipe that separates both vessels through a needle regulation valve, which will enable slow gas expansions.

The vessels can work either individually or jointly, allowing processes where air flows from a pressurized vessel to the atmosphere, from the atmosphere to a vacuum vessel or from a pressurized vessel to a vacuum vessel.

The unit includes a temperature sensor and a pressure sensor to measure the environmental conditions.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- To study of the pressure changes in the processes involves the 1st Law of Thermodynamics.

- Understanding of the 2nd Law of Thermodynamics and its corollaries.

- Different responses resulting from fast or slow changes in a process can be observed.

- Relationship between volume, pressure and temperature can be studied and used to determine other thermodynamic properties.

- Relationship between the pressure and temperature of air can be observer.

- To study the behaviour of a perfect gas and its describing equations.

- Study of the non-flow energy equation.

- Study of the unsteady-flow energy equation (in vacuum mode).

- Study of an adiabatic reversible process (isentropic expansion).

- Study of a constant volume process.

- Study of the conversion of pressure units.

- Study of an adiabatic irreversible process.

- Study of a constant internal energy process.

- Study of the polytropic processes, with the limiting case of n=y.

- Study of the relative and absolute pressures.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TEPGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TEPGC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Peralatan Latihan Ekspansi Termal

Pompa Kalorimeter

Kalorimeter Throttling dan Pemisahan, Dikendalikan dari Komputer (PC)

Peralatan Boiler Marcet, Dikendalikan dari Komputer (PC)

Peralatan Pengukuran Suhu, Dikendalikan dari Komputer (PC)

Peralatan Pengukuran Suhu

Peralatan Pelatihan Pengukuran Suhu

Peralatan Hukum Gas (Hukum Boyle dan Gay-Lussac), Dikendalikan dari Komputer (PC)

Peralatan Siklus Daur Ulang, Dikendalikan dari Komputer (PC)

Peralatan Siklus Daur Ulang

Peralatan Tekanan Saturasi, Dikendalikan dari Komputer (PC)

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie