At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-CPI Stasiun Kontrol Proses Industri

SISTEM INOVATIF

The "AE-PLC-CPI" application is a unit that includes different technologies to carry out four control loops in closed loop: flow, level,temperature and pressure.

BERITA TERKAIT

GAMBARAN UMUM

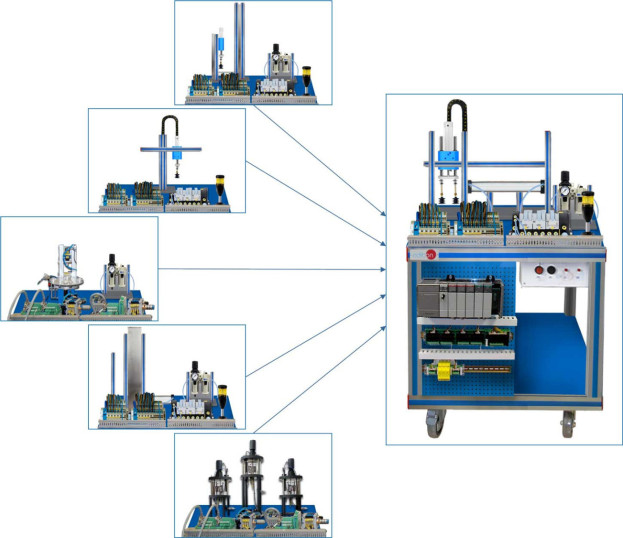

The "AE-PLC-CPI" application is a unit that includes different technologies to carry out four control loops in closed loop: flow, level, temperature and pressure. A flexible system of ball valves and pipe connections makes the configuration of the control loops be quick and easy. The sensors and actuators included in the application allow for the implementation of different types of regulators (P, I, PI, PID) through a controller. In addition, there are elements that generate disturbances in the system so that the response of the control loop is observed.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Implementation of a complex process control system.

- Sensor operation principle: inductive, capacitive, ultrasoundand infrared sensors.

- Actuator operation principle: pump and proportionaldirectional control valve.

With PLC Programmable Controller (Base Unit):

- Structure of a PLC program.

- Programming and use of digital and analog signals.

- Programming of different operating modes.

- Programming of alternative branches (Grafcet).

- Communication with extended I/O remote module.

- Time and response optimization. Programming a PID levelcontroller via PLC.

- Time and response optimization. Programming a PID flowcontroller via PLC.

- Time and response optimization. Programming a PIDtemperature controller via PLC.

- Time and response optimization. Programming a PID pressurecontroller via PLC.

PERALATAN KOMPLEMENTER

6.2.4.- APLIKASI INDUSTRI DENGAN PLC

AE-PLC-SE

Aplikasi Pengendalian Lift

The Elevator Control Application, "AE-PLC-SE", has been designed by EDIBON with a double objective. On the one hand, this application allows to study the main electro-mechanical components that nowadays integrate any elevator. The most relevant...

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie