EMLS Peralatan Pencampuran Cairan/Tekuk

SISTEM INOVATIF

The Liquid/Solid Mixing Unit, "EMLS," designed by EDIBON, facilitates the study and optimization of mixing liquids and solids. It includes a robust support with a variable speed motor and mechanical connections for installing various agitators.

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Liquid/Solid Mixing Unit, "EMLS," designed by EDIBON, facilitates the study and optimization of mixing liquids and solids. It includes a robust support with a variable speed motor and mechanical connections for installing various agitators. These adjustable components adapt to different mixtures and industrial applications.

The "EMLS" allows controlling the intensity of agitation and using agitators of different sizes to achieve homogeneous dispersion. The height-adjustable mobile platform enables positioning the agitator according to the volume and type of material in the tank. Transparent tanks facilitate real-time observation, and lids prevent splashing.

This unit enhances the knowledge of students and professors in chemical engineering. Students gain practical experience complementing theoretical learning, while professors can demonstrate complex principles clearly and tangibly. Safety features automatically disconnect the system when the door is open or the agitator is in the highest position.

The "EMLS" is designed for optimal functionality and safety, featuring an adjustable motor, vertical adjustment system, interchangeable agitators, and transparent tanks. These characteristics ensure a safe and efficient working environment.

The "EMLS" is an advanced solution for education and research, providing a deep understanding of liquid/solid mixing. Its versatile and secure design makes it ideal for students, professors, and researchers, enriching knowledge and preparing future professionals for challenges in chemical engineering and other industries.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Visualization of fluid fields.

- Power required in the agitation process.

- Suspensions of solids in liquids.

- Formation of solid-liquid solutions.

- Emulsion of immiscible liquids.

- Mixing of miscible liquids.

- Heating process of liquid mass.

- Test with models at scale.

- Quality of mixing / mixing time.

- Power speed of the different agitators.

- Demonstration of the different factors (tanks, deflectors, agitators...), that affect the mixing, using visualization techniques and appropriate measurement.

PERALATAN KOMPLEMENTER

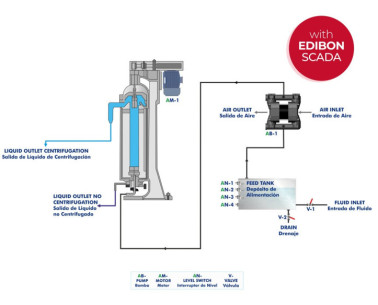

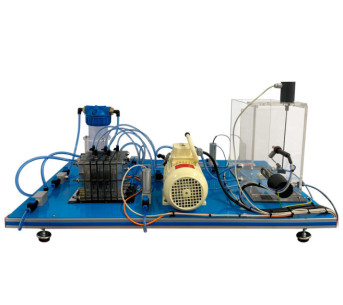

Pemisah Sentrifugal Semi-Kontinu 1000 L, Dikendalikan dari Komputer (PC) dan Layar Sentuh

Peralatan Filtrasi Kontinu dan Diskontinu, Dikendalikan dari Komputer (PC)

Peralatan Filtrasi Kontinu dan Diskontinu

Filter Press Pelat dan Bingkai, Dikendalikan dari Komputer (PC)

Peralatan Filtrasi Lapisan Dalam, Dikendalikan dari Komputer (PC)

Peralatan Filtrasi Lapisan Dalam

Peralatan Studi Sedimentasi

Tangki Sedimentasi, Dikendalikan dari Komputer (PC)

Tangki Sedimentasi

Tangki Filtrasi dan Drainase, Dikendalikan dari Komputer (PC)

Tangki Filtrasi dan Drainase

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie