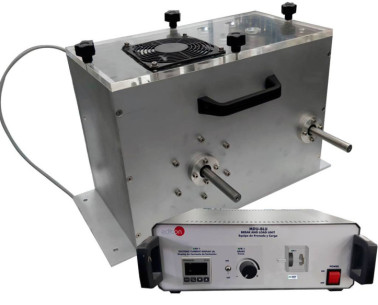

The Basic Unit of Mechanical Drive Systems, "MDSU", consists of a main frame where a series of accessories and elements are arranged, distributed in modules of different level, thought to introduce the user in the field of mechanical systems and their components. The main frame can be divided so that different working groups can work at the same time. The elements are assembled to the main frame by quick release fittings that facilitate the assembly of elements in the configuration required by the user for the study. Apart from the main frame, a variable speed rotary motor is included. It will generate the initial motion along a shaft that will drive the rest of mechanical elements of the system, such as belts, gears, chains, etc.

The unit includes a brake to determine the torque generated by the motor directly or along the mechanical system designed by the student using basic components of any mechanical system. Finally, fundamental aspects of mechanical equipment maintenance will be studied, as well as the tools and products employed for that purpose.

The unit has all the necessary safety measures, mechanical and electrical protections, disconnect switches and emergency stop push button for a safe operation.

クッキーの設定

クッキーの設定